Herr Horn (I have seen his name given as both N.V. Horn and V.G. Horn; not sure which is correct) was an engineer working in the R&D department of Mauser at the end of WWII, and he designed one of the many different experimental last-ditch rifles that was conceived in the last years of the war. The requirements for these rifle designs were to use standard MkB-42/MP-43/MP-44/StG-44 magazines, weigh 4kg (8.8lb) or less, have a barrel the same length as an MkB-42 (413mm / 16.3 in), and to be select-fire with a cyclic rate of approximately 500 rpm. And, of course, they should be simpler and cheaper to produce than the standard sturmgewehr while maintaining it’s combat effectiveness. Initially the guns were required to be blowback operated, in the interest of simplifying production and design. Of course, this was problematic – the bolt required to safely contain 8mm Kurz without a locking system would take up a large percentage of the allowable overall weight.

Some designers continued with the blowback system, most notably Barnitzke, with the Volkssturmgewehr Gustloff (aka VG1-5) and Maier with the Gerät 06H. Horn, however, decided to add a sort of gas system to delay the opening of the bolt.

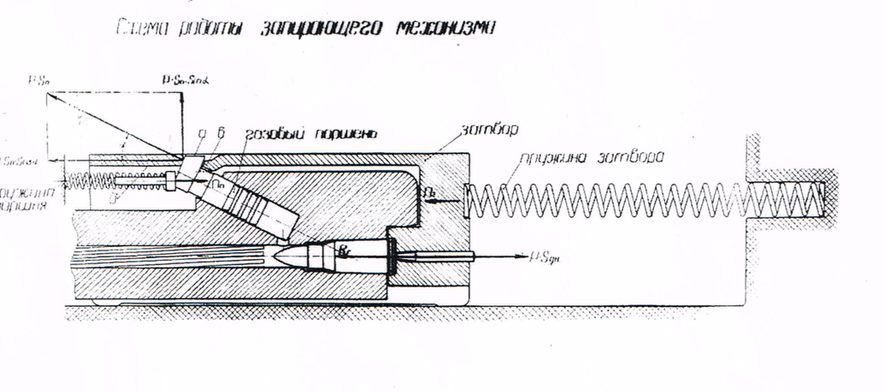

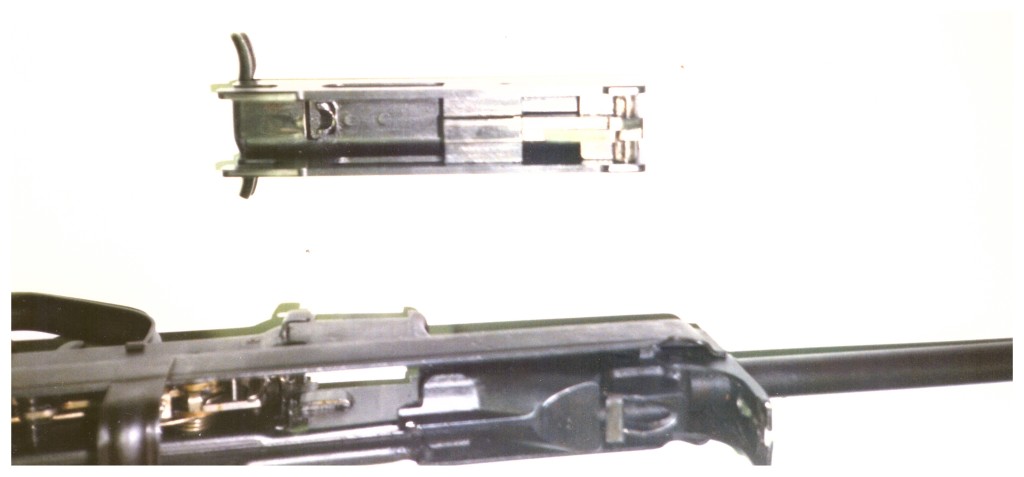

Horn used a barrel fixed in a stamped sheet metal receiver, with a long bolt much like a pistol slide. Above the chamber was a small gas piston which was connected to a gas port just in front of the chamber. When the rifle was fired, gas pressure would immediately force the piston up and into a recess cut in the slide. The bolt was able to travel rearward only about 1mm before the piston engaged, and then the rearward pressure on the bolt had to fight against the angled surface of the piston engaging in the bolt. This was not a truly “locked” system, but rather one of gas delay, as the piston was intended only to counteract some of the chamber pressure and slow down the opening of the breech.

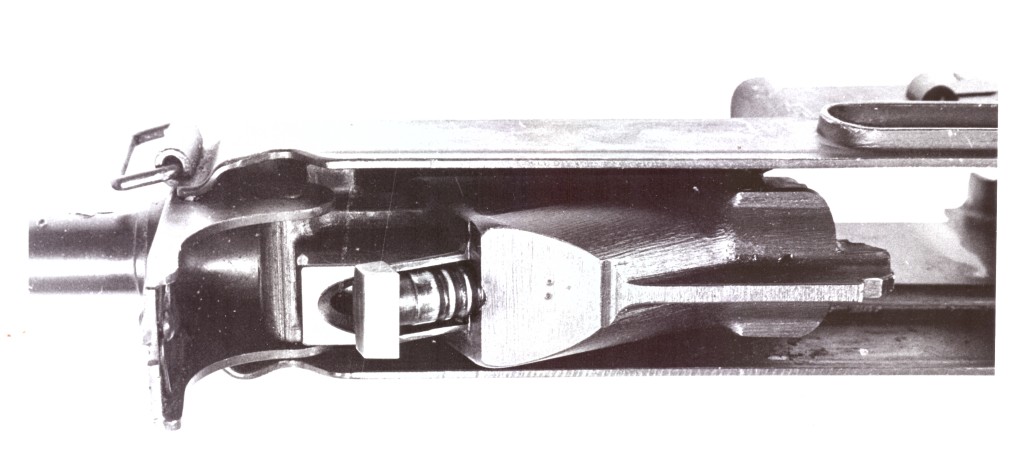

In early testing it was found that a free floating piston caused problems. If the rifle were manually charged while being pointed downward, gravity could pull the piston forward and cause a nasty double feed type of malfunction. This was addressed by adding a light spring to constantly push the piston downward. The spring force was not enough to have any adverse impact on the firing cycle, but it would counteract gravity.

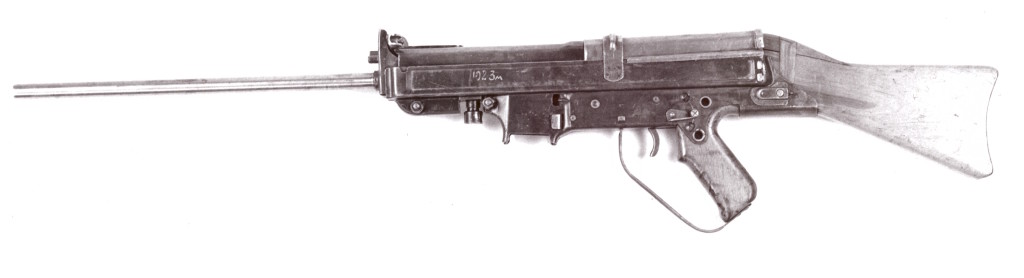

Another interesting element to take note of is that Horn extended the magazine supports in the front and back of the magwell as compared to the StG-44. These magazines when fully loaded were both heavy and long, and would bounce back and forth on firing, eventually wearing a crease in the front of the magazine where the magwell ended. This would eventually cause functioning problems. The sides of the magazine well could not be altered because of the overtravel stops molded into the magazine stampings, but the front and rear could be extended, which Horn did.

The Horn rifle was hammer fired, and used a quite complex fire control mechanism to prevent out of battery firing and bolt bounce. Either of these would be quite dangerous to the rifle, as the bolt was much lighter than would be required for safe firing without the use of the delaying piston.

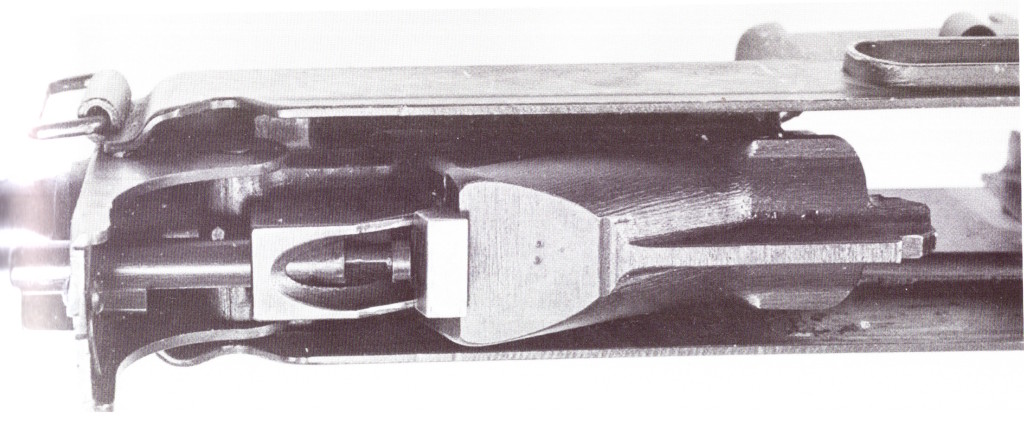

The Horn bolt was a long affair rather like an automatic pistol slide, with the actual breechface located in the center and a long surface running forward over the chamber. This forward extension added mass to the bolt and also provided the area for the retarding piston to lock into the bolt. It had two wing-like grasping handles at the front to allow easy grasping.

A handful of these rifles were made during the war – the Russians reported capturing 5 at the testing facility at Kummersdorf and another 4 from various units in the field. Horn was one of the engineers they captured, and after the war he continued to develop the concept briefly for the Red Army. Like Barnitzke, Horn reported that when he arrived in Russia, his office from Mauser had been perfectly recreated for him, right down to his coat hanging behind the door. Only the view out the window was different.

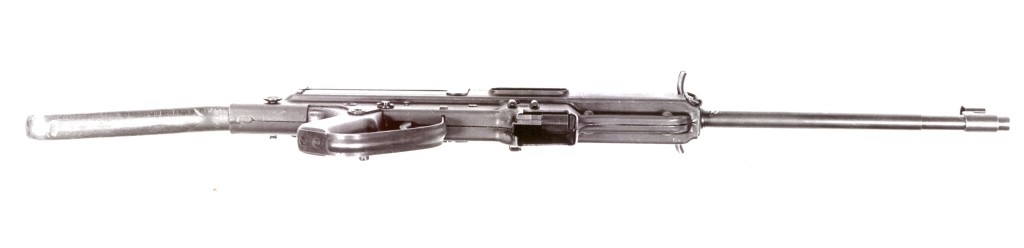

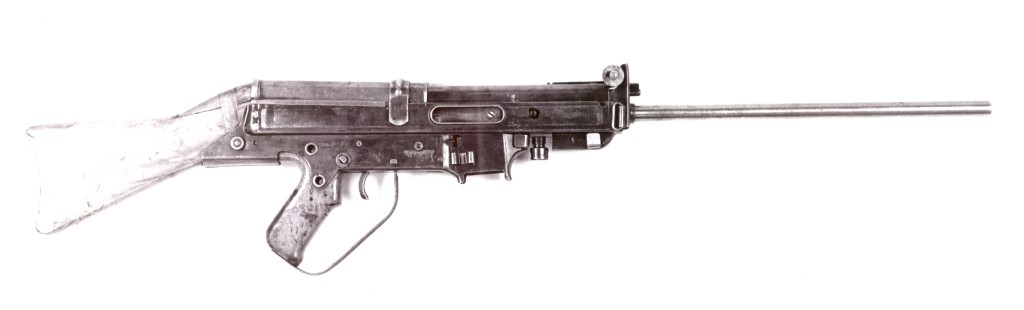

Anyway, Russian experimentation was limited to two examples, I believe. Here is one of them, which appears to have been fitted with a pressure measuring device under the chamber. Note the lack of front sight, where the German production guns used StG-style front sights. Also, note the full-hand style of trigger guard, which was copied form the original German production guns. This rifle was designed with the expectation of use on the Russian front, where the ability to use it with gloved hands was an important factor:

In Russian testing after the war, the Horn rifles were found to have a number of deficiencies. For one thing, they were awkward to handle, suffering from being excessively wide and from being poorly balanced, with too much weight too far forward. The charging handles were found to be inconvenient when crawling (they would catch on the ground) and too far forward for easy use when reloading in a prone position. The selector lever was not convenient to use from a firing grip, the buttstock was not attached securely enough, and the magazine release didn’t always work well. Of course, these were rifle still very much in the development phase, and all of these problems could have been addressed.

It seems that Horn had a rather novel and interesting mechanism, and it may well have had real potential had it been developed further. The Russian experiments ended without that development, and I do not know why. Horne did return to the west shortly before his death, but never spoke much about the work he had done in Russia. Interestingly, the only reason he was captured by the Russians was because he had been at the testing center at Kummersdorf when the Russians occupied Berlin – the Mauser facilities and most of their staff ended up in Allied occupation zones.

Three Horn rifles are still in existence, in a museum in Russia. Larry Vickers recently visited and was kind enough to send me these photos of one of the guns (a German example):

I also have some photographs of this rifle being disassembled some time before the advent of digital cameras (they are scanned photographic prints):

Interesting design and a definitely a Forgotten Weapon. Thanks for sharing!

This looks like a good system for a submachine gun. The bolt would be lighter for a given RoF, so a simple compact and controllable weapon could be produced.

Click here: http://strangernn.livejournal.com/910508.html

too see disassembled Horn rifle.

“In Russian testing after the war, the Horn rifles were found to have a number of deficiencies.”

Yes, poor ergonomics was noted, but on other hand its reliability was incredible high, above linked texts states that 1900 fired without ANY failure caused by mechanism in wide range of conditions: without grease, sand, temperature from -60°C to +50°C.

“The Russian experiments ended without that development, and I do not know why”

Russian has many indigenous proposals for new avtomat for Red Army, too see some of them click here: http://forum.ohrana.ru/ognestrelnoe-oruzhie/thread557.html

Click here: http://www.kalashnikov.ru/upload/medialibrary/44a/020_026.pdf

to see high-quality photos and cut-away blueprint of that fire-arm.

Lots of potentially forgotten weapons on that link.

Had the gun been developed further, could it have competed with the HK G3?

It does sort of resemble a G3.

Superficially…

I would think so if it came into service and not the STG45(M) or the other options

i think, in the immediate postwar period it was anybodies game, had for instance, ludwig vorgrimler been captured by the soviets instead of making his way to CETME in spain the story would likely be different. how different i wouldn’t speculate. lots of ingenious designs ended up in the circler file because of unfavorable circumstances. on the face of it the horn prototypes had just as much going for them design wise as the mauser stg 45, just no post war devotees.

Fascinating. The Gerät06 seemed much more refined and still cheaper than the Stg44, hence slated for StG 45 status… I wonder to what degree–if at all–Herr Horn may have been influenced by the carbine Williams short-stroke piston on the selbstladekarabiner M1? The carbine taps gas from the barrel quite close to the chamber, which slams a short piston to whack the operating rod assembly/bolt carrier, which moves back while the projectile leaves the barrel, and then cams the rotating bolt out of locking engagement to cycle the weapon. Meanwhile, Horn’s taps gas even closer to the chamber, in fact, from the chamber, to slam a small piston up at an angle to “grab” the slide/bolt extension and hang there until the bullet leaves the barrel and the pressure drops so that blowback/unlocked operation can occur.

One of Mr. Vickers’ photos shows the Gerät Neumünster or MP.3008 there to the rear of the Horn rifle… Take the Sten Mk.III, and if anything, make it even cheaper ans simpler to produce.

Thanks all round for the informative brief on this forgotten prototype!

Probably not, since the gas bled to piston serves to delay the blowback action in Horn, versus opening the locked action in the M1, very big difference, also I dont think these rifles were available in the Eastern parts of the Reich where Horn was made.

Ported barrel so close to the chamber also serves in some degree to lower the pressure in the barrel, so it could safely use (by russian account) 0.9kg bolt (compared to vg 1-5 of 1.4 kg)

One potential flaw of the whole idea and design could be in excess fouling of the piston area, also maybe above than normal erosion…

Maybe that was the reason of abandoning the Korobov first design.

Since many russian designers experimented with german captured prototypes, and tried to perfect them (only thing they didn’t have was roller locking), if some russian archives someday open and shed a light on a subject, the gun community would have lot of valuable information that is hidden 60 years without needing to recreate the concepts and results.

Very little amount of that kind of info flowed out of that country, especially during the Cold War, and west is generally unaware of lot of their technology achievements, sometimes made with fairly crude methods and tools, but with surprisingly effective results.

“Maybe that was the reason of abandoning the Korobov first design.”

So far I know there was not clear technical reason of abandoning this design. Despite it shows good results in test, it was decided to adopt improved AK (AKM).

In Soviet Union some weapons system were chosen, not because technical advantages, but due to have more support from deciding peoples.

There is anecdotal story that Degtyaryov convinced Stalin (which favored Degtuarov) that machine gun that prove itself superior in test should enter service, so SG (Goryunov) machine was adopted, as it proved to be better.

Does the plug not vent gas then?

The gas plug pops out of it’s chamber revealing its gas sealing rings, perhaps it vents thus.

The spring has been removed on the popped out photo, but it must vent presumably.

“One potential flaw of the whole idea and design could be in excess fouling of the piston area, also maybe above than normal erosion…

Maybe that was the reason of abandoning the Korobov first design.”

Erosion, yes. Not sure about fouling. The M1 carbine design: “A gas port is drilled at an angle through the gas cylinder and barrel, entering the bore about 4 1/2-in.from the rear face of the barrel. This rearward positioning of the gas cylinder and port makes it possible to take the gas from the bore close to the chamber, before cooling can take place, thus minimizing carbonization.”

I assure you that Mauser designers would have had access to captured Allied weapons.

The M1 carbine has a captive piston to operate the operating slide/bolt carrier because it is a gas operated design. The Horn is merely a form of delayed blowback, in which the small captive piston “grabs” to prevent the bolt opening too suddenly. The carbine’s captive piston is returned by the spring-loaded, reciprocating operating slide/bolt carrier while the Horn has a little spring-loaded lever to push against the piston.

Maybe the manner it vents, does cause fouling problems, it appears to just blast it out all around the plug around the same gas ring presumably, which given the plug has to fit back into it’s channel again may cause stoppages.

“Horn rifle was hammer fired, and used a quite complex fire control mechanism to prevent out of battery firing and bolt bounce. Either of these would be quite dangerous to the rifle, as the bolt was much lighter than would be required for safe firing without the use of the delaying piston.” Maybe a two part assembly would be better i.e. Have a gas plug like of an Sa80 emanating from the the barrel port, with it’s gas piston on top- The Horns plug top being attached to its top, so it vents around the side.

” I dont think these rifles were available in the Eastern parts of the Reich where Horn was made”

M1 Carbines were common enough that the Germans had an actual nomenclature for them (Selbstladekarabiner 455(a)). Did they issue a whole bunch out? Nope, and probably primarily to units like SD detachments, that were high prominence but low priority for ordnance. But the Germans were certainly well aware of the M1 Carbine and had plenty of examples to play around with no later than 1943. Undoubtedly enough to have examples available to arms designers

Again, top notch material, but as one commenter noted, in original russian article they numbered some good points of the rifle, not just deficiancies.

However, the (very unconfirmed!) story of “Office replicated in the Russia”, and “Died shortly after return to the Germany and never told anything about time in Russia” is often circulated on the internet these days, with Hugo Schmeisser in lead role, but it seems like it’s become of a generic story, just change the names !

Its often used by proponents of nullifying the russian effort to the point of “german engineers made everything for them after the war”, which I don’t think is totally false,

but again all this is speculation and obscure (much like the whole AK story being made/invented by “gifted selftaught tank mechanic”).

Interesting enough, first (out of few) Korobov 454 design after the war used this very system (speaking of ingenuinity) but I don’t seem to be able to find any pictures of the inside of the rifle, or even closeups, it’s apparent by the elongated barrel trunion area that it is very similar to the Horn/Grossfuss rifle.

That link below, mentions the 454 “1947 GA Korobov creates Tula CDB-14 new machine TKB-454-43 (TKB – Tula Design Bureau), the first time equipped with a system of free gas brake light shutter, provides ease of design, cost reduction in the production of and facilitating weapons.” gas brake light shutter is presumably the one with Horn type system.

http://tonnel-ufo.ru/eanglish/weapon/korobov-tkb-454.php

Bemusimg Russian transliteration aside “And serves to support the combat larvae during the shot.” Combat larvae…

“Combat larvae”

There is story, I don’t know whatever it is true or not, but is good example of electronic translators “skills”: Americans once developed English-Russian Russian-English translator, to test it they put sentence in EN-RU and its output to RU-EN and compare that with initial input, result was interesting:

INPUT: The spirit is willing, but the flesh is weak

OUTPUT: The vodka is good, but the meat is rotten

I hope the translators at NATO are better “OMG! THE RUSSIANS HAVE SECRET COMBAT LARVAE, SPETSNAZ INSECTS WILL HATCH IN OUR TOWNS AND CITIES AND PESTER US TO DEATH!!”

Get the Exterminator! [dramatic music]

Is there a really good website or book for Korobov’s designs? I’ve become fascinated with rifles that don’t require a gas system and have the operating components centralized in the rear.

None I am aware of…

Lot of ex Ussr info is still in shadows, and waits for the future to be unveiled, but I only hope that it will not be lost or forgotten in the process, since with states that do not have liberal gun laws like Usa, the research and whole gun culture is severely limited and sometimes forcefully hidden from people.

Hm. It occurs to me that by varying the size of the gas port (which governs pressure as per the Venturi principle) and the diameter of the piston (greater cm\2=more total pressure exerted), this system could be tailored to almost any cartridge, up to and including automatic cannon rounds.

It could not only have made an acceptable assault rifle, it could have been the basis for a simple, easily mass-produced AAA or aircraft cannon. Something that would have come in very handy for Germany about that time.

cheers

eon

“this system could be tailored to almost any cartridge, up to and including automatic cannon rounds.”

What about Rate-Of-Fire?

Cyclic rate of a full-auto weapon is governed by the following;

1. Momentum factor of projectile (muzzle velocity x projectile mass);

2. Bolt mass;

3. Recoil spring tension;

4. Locking system (if any).

Newton’s Third Law of Motion in action. Factor 1 decides how much “reaction” there will be; factors 2-3-4 govern how much resistance to that reaction the system has.

Generally, straight-blowback or retarded-blowback weapons (like this one) need a heavier bolt to reduce RoF to a reasonable figure, defined as “bolt not moving so fast it either rips head off cartridge case, fails to feed next round, or both”.

Some weapons get around this by using a “bolt retarder” or “rate reducer” to act as a drag on the bolt either moving backward out of battery or going forward into it. The Skorpion MPs and the Spanish Astra 903 Mauser “Broomhandle” copy had such rate reducers tucked away in their pistol grips.

To govern the RoF of a heavy auto weapon built on the Horn principle, you would be adjusting the size of the gas port to govern gas pressure exerted on the piston head, the size of the piston head itself, bolt mass, and recoil-spring pressure.

Note that while the rifle is hammer-fired, there’s no reason an autocannon couldn’t be a fixed firing pin, advanced primer ignition “slamfire” type, as firing from an open bolt wouldn’t be much of a handicap in that application, allowing cooling airflow through breech and barrel between bursts.

Also note that this helps to reduce RoF still more, as the recoil thrust of the case head has to arrest the forward motion (inertia) of the bolt before it can commence rearward travel.

In 20mm, I’d figure the RoF at around 550-600 R/M. Keep in mind that for a single-barrel, non-revolver breech cannon, that’s a lot of steel-jacketed HE going downrange every second.

Enough to put eight or ten rounds in a one-second burst into a Mig-15.

Or an F-86 Sabre.

cheers

eon

That would have been a very welcome development at the time.

Calculate the raw materials needed to make aa cannon compared to rifle, plus aa ammo too.

People are astonished today when they found out that one artillery shell costs like a box full of ak’s…

But you need big guns obviously in wars.

Wars are a bad idea, better spend the money on peasants, mind you peasants need jobs… War production. Which idiot invented the A Bomb.

Yeah, but not in the volksturm anything goes phase. They should have thought about rationalizing in ’41, just like Ussr and Gb, in 44-45 it came too late, theyve wasted too much resources on high tech high quality weapons that they start to lose pretty fast after 1943…

Oh well, that’s good speaky ze Deutsch etc.

It was a novel idea, a product of “last ditch” thinking I think. It probably has potential for future development, it’s interesting that it didn’t require a fluted chamber seemingly as delayed rather than locked system. It’s good this forgotten weapon, has been remembered so to speak.

It doesn’t rotate like I thought, the plugs lug thing just rides up and down its angled “rails” because it was never really finished either by the Germans or Soviets it does provide the basis for a “What if” design, if anyone can come up with one. Would this perfected weapon, have become the principle arm of Ze Nazis victorious counter attack using an Zombie army of reconstructed casualties brought about by Mengele.

Or the first auto-rifle design that could be built in a post-Smash scenario, because it’s less complex and demands less sophisticated construction materials, techniques, etc., than even an AK-47.

cheers

eon

Aye that.

Not needing a fluted chamber must be better for a “Folk” rifle, it’s simpler not having one.

It’s one less machine to transport to the mini Reich towards Osterreich, a chamber fluter.

The trains will need all the gear for reactivating dead Soldatens, including said stiffs.

The Horn would be many times easier to make than an AK. Especially on smaller scale production.

I’d never want to have to make an AK without having forging to work with. For a normal rifle of the type, it would be hard to beat the Leader for making.

Theoretically this Horn thing is the best thing to happen to Volksweapons since sliced bread, was… For, like… Ducks. It makes perfect sense end of Nazi Germany everything is proper fecked, that’s why they came up with it, how they did even.

It just wasn’t perfected, the Ak explains why the Russians didn’t that worked they weren’t proper fecked.

“The Horn would be many times easier to make than an AK. Especially on smaller scale production.”

You think about AK-early or AK-late? That designs are different manufacture-wise.

AK-early (dubbed “Type 1 AK” in West literature) was produced in stamping technology, but then available technology caused many flawed examples, this led to AK-late which was manufactured by milling.

AKS (AK with folding stock) also can be found in stamped and milled variants

AKM (AK modernized) reverted to stamping technology

Make a channel for a horizontal gas plug above the chamber, ¬ shaped but the other way round. Loose the top part of the current plug, make circular piece viewed thus o with a larger diameter half circular piece on it. Pin this through the bolt so the lower half circular piece rests against the plug, have two “barb wire” type springs, round ones with protruding ends sit either side of said “wheel” with one set of ends acting on the wheel via pin running through it on the left circular part, the other set of ends stop against a further pin running through the bolt. This makes the wheel sprung in a manner that ensures the half circular piece is vertical, when it can… It can, when the top of said piece is aligned with a hole in the receiver, gas hits the plug, the plug prevents the wheel turning, the wheel is engaged into the receiver preventing the bolt from moving.

That way the bolt sits behind the chamber more conventionally, stick the cocking handle/anti bolt bounce thing off the Hk sporter on a recent article on it.

Vents by the plug popping out into the chamber, possibly causing gunk… But, there’s no rotary bolt to mess up.

Theres a cut out through the front of the plugs channel, a pin which passes through the plug into this channel stopping it from blowing out. Modify the plug so it extends past the barrel port, for the above, cut a /| shape into the plug which sits above the port when the bolt pushes against the plugs front via the wheel.

With the existing bolt setup, there’s no reason it couldn’t have a single “upright” cocking handle near the front of the bolt, similar to that on the AR-10.

Or a folding one on the side near the front, rather like that on the MP-5.

cheers

eon

Well so long as you can cock it, and it de-bouncifys the bolt.

It must need modifying otherwise they’d be still in use presumably, in some form. I reckon Herr Horn was onto something though.

If gas pressure is enough to hold the bolt shut untill the bullet has left, it shouldn’t need a fluted chamber.

Doesn’t matter that the flat edge of the receiver engaging wheel isn’t contacting the receiver with said edge, it’s sat inside a decent sized recess for it, the rounded edge will help it de-engage.

Aye… It rotates counter clockwise, hmmm… Confusing, it’s the plug so gas against the wheel, which prevents it from rotating thus.

Well, a fluted chamber help with systems with less-than-great primary extraction, by preventing the cartridge case from adhering to the chamber walls.

Generally, pistol-caliber weapons don’t need it because the chamber pressures are lower; rotating bolt actions generally don’t either, because the initial rotation in the unlocking phase breaks the case walls loose from the chamber walls.

For something like .50 BMG in an action like this, I’d go with a fluted chamber, simply because SAAMI pressure on it is 65,000 PSI, about the same as most of the big Magnum rifle rounds (Weatherby, etc.) Autocannon rounds I believe are in the same ballpark for the most part.

The thing is, a fluted chamber isn’t that hard to make. With a proper burr and a rotating workpiece clamp that you can index, you can generally do it with a drill press. Which you would need anyway for heavy work. Any factory capable of turning out heavy-caliber weapons on this principle will have the necessary tools for the job.

For that matter, any factory that can turn out splined-end half-axles for cars or trucks can do it. And that was always a job shop thing in Europe back then.

In fact, they could probably make the whole barrel on their existing equipment, with the addition of a few specialized bits of extra tooling.

cheers

eon

Takes time though, the Gerat06h was reputedly quicker to knock up, so you could knock up more than the Mp44… The Gerat06h has a fluted chamber, but it was cheaper and quicker to knock up, having no fluted chamber would surely be quicker still and if it was cheaper than the 06h better still.

You could use a enlarged Gerat 06h receiver etc as applicable, and put a version of Horn rifles chamber/barrel in it- This version has a triangular ridge running along the top of the chamber, a “see-saw” is then attached to this via a hole through it in a manner which allows it to swivel. There’s a hook on the rear end of the see-saw which sits behind the back of a modified 06h bolt “no rollers in it, 06 type firing pin as appropriate, modified ejector etc” the front of the see-saw rests on the Horns plug, when the plug is down the hook is above the bolt, when it lifts up the hook blocks the bolts path rearwards until the see-saw can return. Tilting bolt sort of…

Probably wouldn’t wish to though, he he.

Were self opening rollers really the best answer hence why they adopted them, or would have if they weren’t defeated by then your opinion Eon? For small arms, in particularly. If so, what about larger guns as you suggested. Do rollers have a limit of practicality, in regards the weight needed to keep them in situ before blowback overcomes the resistance mass is placing on them so to speak. .50Bmg roller system a no go for example, to much oomph going rearwards without putting a car on the bolt etc. Does this Horn lark come into it’s own for bigger things, because locking mechanisms are heavier for bigger things but this could offer a delaying method by widening the plug or such.

The Stecke lock (the actual name of the roller-lock system) can e adjusted in size, ramp angle, etc., to accommodate almost any cartridge.

I used to have a Czech Vz52 with the roller lock that handled even the heavy-loaded Czech 7.62 x 25mm with no trouble, and most of its parts were castings.

The main problem with it is that it requires fairly precise machining, more so than say a Colt-Browning lock.

The “modern” version of the Browning lockup,as on the Glock or H&K USP series, actually was developed by Petter before WW2 for the 1935S version of the French MAS service pistol, as a “war emergency” type that was faster to make than the parent 1935A. It’s about as simple and mule-stupid as a short-recoil locking system can get, and it can just about be “machined” into a platform with nothing but hand tools and maybe an electric drill for the heavy cutting.

Come to think of it, a rifle like this or the VG1-5 could be built around such a lockup. Pretty much eliminating the need for even a gas-retarded blowback system.

Accuracy might be an issue, though. After all, the barrel moves in the vertical plane to unlock and relock. That’s a possible source of wear with high-intensity cartridges (rifle ammunition).

Still, it’s an interesting thought.

cheers

eon

It’s gas delay you need for a fixed barrel though isn’t it, the Cz52 barrel moves in order for it to be locked. If you could improve the efficiency of gas delay .50Bmg Machine guns could be lighter/simpler for example. If you used the Horn system in a different configuration, using it to provide resistance to a set of rollers closing via gas delay this would be working in conjunction with the bolt mass/recoil spring acting against blowback.

“Muzzle velocity bullets on average 38.5 m / s lower than the AK-47 because of the grooves in the chamber” Thats a quote from the Russian website about a later Koborov rifle, presumably the grooves aforesaid are Gerat06h type chamber ones for the same purpose. Does a G3 with the same hypothetical barrel length as a M14 lose velocity in 7.62 Nato, because of chamber fluting?

That’s how I’d do it anyway, have I lost or won ze var for Der Zombie Reich?

Spring load ze plug, deeper ze hole behind unt ze plug.

Port above ze chamber, corresponding to half drilled plug mit ze further port matching die above in das chamber.

Plug even.

The wheel is now mounted above the chamber, spring loaded etc as per. But the bolt has an extension which contains the recess for the wheels bolt engaging lug, this sits over the chamber. The wheel rotates clockwise when gas isn’t pressing the plug against it’s lower engagement lug, the plug is pushed back into its channel by said rotation. The port/channel is that alluded to previously, the plug is just the original one now though minus the end. The wheel is sprung so the semi circle is sat at \ that sort of angle at rest, the plug engages when blowback has pulled said piece |.

Or not, anyway all good, the Horn principle is interesting.

How about this, a circular piece viewed thus o with a pin through it vertically. This is mounted above the chamber, by a pin through the circles centre “the pin aforesaid passes through this” this section above the chamber is so:

|_

| shaped at either side i.e. with a gap in between, the gas port shaped ¬ but the back to front. Sits in the upper part the shape above, the circular piece is pinned through the apex of the _

|

Shape approximately, the upper of the vertical pin, through the circular piece rests against the gas plug in this position. There’s a further pin passing through the circle horizontally, through the other pins. The end of this pin rests against the end of cut out aforementioned, so it would sit under the gas plug. The bolt sits below the end of the verrical pin through the circle, it’s front meets the chamber and theres a protruding lug on it’s forward upperside that rests against the bottom of the vertical pin. Upon firing, gas hits the plugs rear via the port as per, the plug prevents the “wheel” from turning anti clockwise, because the plug is resting against the upper part of the vertical pin, and thus the lower part is preventing the bolt from moving rearwards because to do so the wheel needs to rotate, the shape of the chamber section alluded to above permits this rotation with clearance for the pins providing the function stated. On the return the bolts lug hits the pin through the wheel which was the horizontal one but now is vertical “this is a half pin” in so doing it rotates the wheel back to the original position. The plug is pushed back into it’s chamber when the pin via the wheel rotates, it has a split ring say round it’s front to prevent it from going back overly far i.e. So it’s end blocks the port, there’s a slight recess in the front of the plugs channel to ensure clearance as above. This version loses the springs and more intricate machining, I reckon it works? Sitting above the chamber however makes this part of the gun somewhat bulky, like the original.

The shapes were supposed to be lighting bolt type shapes, before posting formatted the text.

I mean, it uses more parts than originally… But if it provides a more positive lock up, I mean it might not but that’s the idea.

Blowback is probably taking place, but the key is the plug engaging it’s engagement pin on the wheel before said pin has rotated past the plugs channel.

Sort of like a Baryshev AB-762 but using gas, well a gas propelled plug, but not alike.

Modification: There’s an Sa80 type gas plug, with gas piston in the chamber channel only all three are square to prevent rotation, the plug connects to the port, and the pistons end is \ angled to help the pin close it thus provide it with the clearance required when the wheel rotates. The pin won’t quite pass the the pistons end keeping it from popping out prematurely if the gun is held vertically for example, prematurely i.e Above the re-rotating pin, jamming it. The piston over a lug would solve the going back to far thing… The wheel would probably be better being sprung in a manner previously suggested, but this time the spring acts to keep the re-rotating pin in the vertical position.

Speaking of the Baryshev, and thinking of this different configuration of gas lark… If you had a .50Bmg blank inside the gas plug, and you fired a .50Bmg round out the barrel the plug hitting the wheels pin might do the counter recoil thing. Fire the blank first when the wheels pin is | angled, the plug hits it at \ then pushes it back to | it can’t go to / because it smacks into the receiver. When the bullet leaves the barrel a port from the plug into the barrel vents the plug aligned to correspond with the | angle, then the bolt pulls the wheel to \ again untill it reaches – Might be ok for a single shot anti recoil rifle, the above is an approximation obviously. You could fire the blank via a slam fire lark, spring loaded plug, fixed pin behind, with an extension acting as the hammer for the main round when it’s slammed.

Actually cancel the blank thing, not like the Baryshev.

Can this system made into something like “reverse roller-locked”? Short, spring-loaded gas piston with a angled surface on one side, pushing roller into recess of bolt?

Gas would push piston back, and it would hold single, relativly big roller down (if gas system is over chamber) to hold bolt closed. When pressure goes down, piston moves to forward position due spring, roller is now moving free up and down, so bolt can move back.

Just a imagination gone wild.

One of the advantages of roller locking, concept that germans favored before ww2 very much (but were pressed to abandon the concept) is that there are no ports on the barrel, yet you still get reliable action opening and extraction.I suppose with roller locking they were very proud of achieving such thing. Also as I stated before they were mostly pioneers in the area, as apparently russians,as far as I know, did not capture any stg45 rifles to try and reverse-engineer the concept and put it in their assault rifle trials. But the method you suggest could work, Im just trying to point that it is inferior to the roller locking,and application where I see it could be perfected and used, is in cases where there is not possible to make conventional rifle round locking or retarded blowback with rollers (lol the term they abandoned gave me smiles always). Probably the most important aspect of this gun is not the piston itself, but the safety mechanism that prevents out of battery firing, since with only 900g bolt It would end up in maybe not total deadly catastrophe, but at least severe damage to the gun,probably to the point of bending and breaking some parts of receiver

It might well work, it would be worth doing also if your able to. Doubtless it would probably take lots more work, fiddling around with things, calculations etc but still- Simplicity itself! In regards the Horn principle.

Thinking about… A gas actuated system, as oppose delayed might lead to some developments also. If you look at the photographs of plug raised and lowered, that movement could be utilised in itself. Imagine a bolt sat behind the chamber with two plates either side of it acting as an extension, passing past the chamber on each side of it. If the plugs top lug was wider, it could sit in recesess within said extension in the plugs lowest position, upon firing the plug would lift out of these recesses traveling along the extension until the recesses returned.

That way it’s the conventionally locked- Metal lugs in recesses, but it’s unlocked unconventionally by gas… Well, conventionally but not type thing. The amount of lift, would dictate the delay- The recesses are angled to correspond with the lugs travel, so it’s the depth of the recesses.

Do you know what I mean, it’s not the gas causing the delay, you just using the same layout for simplicity. As oppose using a gas piston, etc.

Uses more metal, but it might be more reliable… Depends how good gas delay can actually be, it does make me wonder why it wasn’t worked on more if it has more potential.

Someone needs to find out, were it’s legal to.

If it can work it must use less material than other mechanisms and be quicker so simpler to make, to fulfill it’s original volks weapon criteria.

Mind you the rollers work without it, so it would need to be cheaper easier to make- Would it remove the need for a fluted chamber via creating more delay, and if so does that achieve the above. I imagine a plug sitting in between the rollers preventing them from coming inwards, until they can squeeze a spring loaded plug out the way via them acting on it’s angled surfaces when gas pressure has dropped is what I think your essentially saying in principle JJ but in a different way. Catapult ammo size steel bb’s instead of rollers, free floating in a horizontal channel they can’t come free because of the receiver sides being to close.

>° plug so shaped, smacks between them, they have to

° go outward. A bolt with recessed surfaces at either side would have to pass the expanded balls…

Really that’s all roller locking is but the pressure of the slide is holding the balls in so tp speak as is my understanding.

I quite like the combination idea actually JJ, a gas plug of a similar type and rollers of a sort in this case. With the notion, it removes the need for chamber grooves. I’m going for two .38 cal steel bbs housed inside two horizontal channels i.e. Above and below inside the bolt. Then a gas plug channel ¬ shaped, from the port but back to front, with the plug having a > shaped end if viewed from above. When the bolt is closed the bbs will be pushed into recesses in the receiver, by the plug fitting into a slot for it at the bolt between said horizontal channels, or they will push the plug back into the channel upon firing though the plug will move and/or keep the bbs in the recessess. Gas pressure on the plug is presumed to offer more resistance than bolt mass would to blowback, because the bbs stick out the sides of the bolt therefore holding it until they can squeeze the plug back creating more delay. Theoretically, needs refining etc he he.

Having watched the Gerat 06 part of the Gerat video again, using that bolt, you could use this proposed plug layout as a tappet, but you’d be speeding it up because the carrier impact would be quicker. However, if the plug was acting as the guide rod on the 06h’s bolt, by essentially turning this bolt back to front “while using a 06 firing pin lark” then the rollers would have to squeeze the plug back against gas as oppose the carrier against the recoil spring. The bolt shouldn’t move, because the rollers are engaged in the receivers recesses as per.

So, if the rollers were simplified given a modified Horn system could operate thus as far as I can tell… Would said rollers be cheaper/quicker to use in conjunction with said modified system as oppose fluting the chamber. If so a hybrid Horn/Gerat 06h may have been the weapon to arm ze zombie with.

Authentic- Both actual Nazi systems of the last ditch era.

Gas must offer more resistance, hence the Horn not requiring a fluted chamber i.e. The delay is greater, thus the hybrid should reflect this in regards the rollers having to force themselves free of gas pressure instead of recoil spring/bolt mass both via the shaped surface holding said rollers into the recesses.

Should make some, market it as a “what if” what if Hitler counter attacked across the Oder with a Zombie army armed with historically probable hybrids in 1945, who wouldn’t want one of those along with a fancy dress S.S camo uniform, plastic tin hat and a Zombie face paint kit all in for 899.99 bucks use actual rollers from a G3 say.

A pin, instead of a machined half circular thing. Engagement surfaces are still there, vertical pin, horizontal pin via the circular “wheel” a pin straight through the circular piece.

Scheisse, all seems to be going wrong now… Probably better doing this sober. Can it be in the bolt, tut.

FANTASTIC ARTICLE!! VERRY INTERESTING !!

“Cyclic rate of a full-auto weapon is governed by the following;

1. Momentum factor of projectile (muzzle velocity x projectile mass);

2. Bolt mass;

3. Recoil spring tension;

4. Locking system (if any).”

****************

and also the length travel of the bolt.

the mp40 and the ppsh41 have similar bolt weight, but ppsh have shorter bolt travel and a buffer.

it’s would be fun to make a replica of this thing….

http://fr.scribd.com/doc/76267633/sturmgewehr-grossfuss

it’s not thee same document as above, there is 2 more pages.

Interesting, bit more info etc.

Another excellent piece about a forgotten weapons that has a very interesting method of operation. I’ve known about the Horn for a while, but you certainly did greatly increase my knowledge about it.

Plus what you’ve written, does give a bit of encouragement making at least a test platform of it. I hope to do that with both the Horn and a Clarke in about 4 years.

You really do come thru in giving information about the gun that I had an interest in previously to you featuring them. To name a few, the Liu, VG1-5, Horn.

How if you are ever able to locate that farmer in Tennessee who has a Clarke carbine I hope you will be able to work something out to do a feature on that.

Confusing myself, no, sorry, but I want my zombie Nazis to win. Mine you understand, my army of Frankenstein Nazis, because they are mine with me as der farter, a strong farter for a farterland which will last a thousand farts. What?

Needs a bayonet lug.

The MKb/StG family never had bayonet lugs, mainly because they were a bit too short for the bayonet to be practical. The FG-42’s “spike” bayonet was regarded by the Fallschirmjager about the way the British Tommy thought of the spike for the No. 4 rifle- either a bad joke or a tent-peg.

Bayonet fighting is more of an art than a science, and most post-1940 rifles aren’t well designed for the job.

Neither are the blades they stuck on them. The most ludicrous combination being a 5-6″ bladed knife-type bayonet (good camp knife) on the end of a bullpup rifle (aside from keeping somebody from snatching it from you by grabbing the barrel when you enter a doorway in MOBUA, pretty much useless).

The folding bayonets on Chinese AK and SKS clones were mainly for morale boosting for the troops in drill, looking cool on parade, and intimidating unarmed civilians.

(“This is a Goa’uld staff. It is a weapon of terror. Its purpose is to intimidate the enemy.

“This is a P-90. It is a weapon of war. Its purpose is to kill the enemy.”

-Col. Jack O’Neill, Stargate SG-1)

BTW, very few men were killed by bayonet during the American Civil War. Bayonet “charges” were almost unknown. At Gettysburg, Joshua Chamberlain’s Maine Volunteers fixed bayonets and walked down the hill to break the Confederates’ morale and make them retreat or surrender- because the volunteers were completely out of ammunition. It was a bluff that worked.

That’s about the best you can say of a bayonet even today. Especially on a carbine-length or shorter platform.

cheers

eon

Well I’m shocked, next you’ll be saying there’s no point cavalry having swords.

They usually got slaughtered by machine guns or artillery in open plains. Polish cavalrymen tended to attack German troops who didn’t have conveniently located panzer support. The result was that whichever light panzer came to the rescue generally found not horsemen but Polish or captured German anti-tank guns where a company of German soldiers once screamed “mommy.” Said guns were now in Polish hands!

Did I mess up?

No point in having cavalry, actually. Rifles settled that before the machine gun ever showed up.

Charging infantry with muskets that can’t hit reliably beyond 100 yards? Doable; a horse at full charge moves about 35 MPH, or 17 yds/sec. You have six seconds to close during which the PBI will get off one volley at you if they’re already loaded. Chances of them hitting your horse, about one in three. (Chances of breaking your back or neck when horse goes down, 50/50.) Note that infantry tended to fire by ranks, by the numbers, so odds are at least one rank will be able to “let you have it”.

Charging infantry with rifle muskets that can hit a man sized target consistently at 250 yards?

Cavalry is screwed. They shoot the horse out from under you at 300 yards when you’re still moving at a maneuvering gallop (20 MPH, 10 yds./sec). (Still a 50/50 chance you’re crippled or killed when you hit the ground.)

Congratulations. Your (surviving, unhurt or lightly injured) saber-armed cavalry are now badly-underarmed light infantry.

I might add that after the invention of the Welsh longbow, the crossbow, and gunpowder, being a horse on the battlefield isn’t a viable career choice. See Crecy, Agincourt, Plains of Abraham, Salamanca, Waterloo, etc.

cheers

eon

Mounted infantry would provide protection against buried I.E.D’s in that your horse would offer you some protection, the 1912 cavalry sabre is a good sword it’s a skewer. Bayonets are vital though, for tactical psychology.

Fixing bayonets means folk will attack more aggressively, because they know the enemy doesn’t like it up them. The Sa80 isn’t ideal for actually using the bayonet, in regards length and it’s layout. The bayonet though is designed for it, in regards making it as practical as possible. It’s very thick, and on the end of the rifle if you stuck someone and twisted the pistol grip it would snap ribs like twigs.

The SA-80 bayonet, like the M9 bayonet for the M16A2, is an extremely good utility knife. The reason most Civil War soldiers carried sheath knives is that the epee’ bayonet was completely useless for camp chores like opening tins of food, cutting firewood, etc., for which a sturdy, sharp fixed-blade knife is indispensable.

According to one of my ancestors who was with the Ohio Volunteer infantry, the epee’ bayonet had exactly three uses in camp; as a roasting spit, candle holder, or ersatz tent peg.

cheers

eon

You forgot about the Japanese Type 30 Sword Bayonet. While it was of questionable use when fixed to the standard Type 38 Rifle, the Type 30 Bayonet handled like a machete and probably served as one when going through thick jungle. Remember, in the jungle, sometimes its better to use bladed weapons when the game turns into “search and destroy.” The usual set up for stealthy infantry fights in the CBI theatre pitted Japanese troops with bayonets and katanas (both the officer’s mass-produced shin-gunto and family swords brought into service) against British Commonwealth troops with machetes, Nepalese Gurkha troops with Kukris, or whoever else stowed the guns and whipped out knives for dirty work.

And the Polish 49th Hutsul Rifle Regiment practically annihilated the SS-Standarte Germania by bayoneting almost all of them to death in the middle of the night. It was horrifying to the Germans who reclaimed the place only to find all the original heavy equipment burned to ashes and all the German corpses sporting looks of terror on their faces.

Nothing wrong with spike bayonets “who likes needles” think of it like that, aye you’ll run, kilts flapping in the wind.

Ever read about how the Royal Army took Mount Tumbledown in that little fracas where they evicted the Argentinians from the Falklands/Malvinas, Eon?

Visually it looks a little like the UMP.

This is apparently an extreme design born out of necessity; kind of dicey actually, with questionable range of safe operation.

But what impresses me part of preceding Stg line of rifles is absence of excessive amount of ribs and ridges. This is something the soldier would appreciate during cleaning.

I’ve been waiting to read about this one for years — thanks, Ian! I’ve always wondered why a delayed blowback mechanism on these principles hasn’t been tried more often.

If you look at the Russian schematic drawing of this mechanism, I think they didn’t do it like say a P7 “I know this didn’t exist, I mean the logic of the design” simply because the cartridge is too long in relation to how close the end of the plug has to be to the port. In regards the size of the plugs chamber having to be of such a size, which it couldn’t be because of the bolts so plugs amount of rearward travel to facilitate feeding the cartridge. Or is it, you want metal vs metal or both.

The curved sort of indent part of bolt above the Russian b type symbol, that points to the plug, would close the gap between it and the corresponding shape on the uppermost front part of the chamber block. When the plug is lowered,allowing the forward part of the bolt to pass it. I missed that when I thought the plugs end rotated out of the recess in the bolt, a so shaped rotating plug would facilitate it disengaging the bolt if it was designed differently- As I rambled about in a previous article.

I’ve just been having a doodle, with interesting results I think. I’ve crossed the hybrid Horn/Gerat06h idea with a Fg42, the port is now straight down from just in front of the cartridge mouth into the original piston tube. The port now leads to a chamber for a gas plug, the plug ends in a shaped surface section as alluded to previously, the flipped 06h bolt head is attached on the underside of the bolt.

The bolt doesn’t rotate now, but it is cut to allow a firing pin block and bolt holding block to fit inside.

The bolt holding block has a recoil spring guide rod attached to it’s rear, the guide rod fits through a “washer” which screws into the old buffer attachment threads, the rod extends through this into the stocks old buffer compartment when the spring is compressed against said washer when the bolt holding block moves rearward.

The top of this block is drilled through it’s side as is the bolt, to facilitate a pin passing through it- Holding the bolt to the block. The firing pin block which engages the sear, compresses a now stronger spring around the firing pins rear as a guide which extends out the rear of the bolt, the pins front is in it’s firing pin channel.

At the front underside of the bolt, there’s a modified 06h bolt head “just the rollers and channel for the locking piece i.e. The shaped surfaces” which is flipped so said channel faces the chamber, the firing pin block when fired stops against the rear of this piece. The recoil spring pushes the bolt up against the chamber, the firing pin block free floats inside the bolt it’s rear is up against the bolt holding block when cocked.

Theres a port from the chamber, in front of the cartridge mouth heading down into what was the piston tube. Instead of a piston, theres a channel running from the port to the below the chamber mouth. Inside the channel there’s essentially a G3 locking piece “The shaped surfaces” but with gas rings on it’s rear tubular section. The channel is shaped to accept this, theres a spring which goes around the tubular section stopping against the channels tube shape. The spring is compressed by the rear of the shaped surface block to it’s front, theres a cut in the middle of the locking piece this facilitates a pin to be put through the bottom of the channel to hold the locking piece in a sprung postion while allowing it to move rearward.

Which ensures the locking pieces end is forward of the port from the barrel.

The locking piece is inside the bolt head, pushing the rollers into recesses, in what was that part of the piston tube when the bolt is fully forward. Upon firing, gas holds the locking piece in position until the bullet leaves and the rollers then squeeze the locking piece back against it’s spring, the port vents into the barrel. The bolt then moves rearward with the firing pin block inside until the bolt returns and the firing pin block is caught by the sear.

Saves weight and complexity, that’s a basic outline, seems basically sound. Delay is by the bolt mass held in place by the recoil spring, and the rollers engaging recesses held in place by the locking piece which is backed by gas pressure instead of the bolt mas/spring as is usual- So if that works, groovy he be.

Aye… So the blowback needs to be insufficient to pull the bolt rearwards- Therefore pulling the rollers inward via pushing the locking piece rearward, until gas resists this rearward motion of the locking piece.

The locking piece spring is also giving it a wee boost.

Tell me why this isn’t feasible then?

Schweinhundschnellgasverduckschloss.

And good evening.

Well I am quite pleased with that, doodling via a paint program with a schematic of a Fg42 mk1 was really quite sexy.

Well I think it’s a good idea, Mk45 Smg gun lark. It’s right, a hybrid with provenance… Horn was captured over there, Voldemort whatever he was called was captured over here. If niether was captured because the Russians etc, weren’t near. Ordnance would have put the two together, the Horn unt ze 06h obvious “aye it is” eventually. Apart, nobody ever did- Recreating someones office, when their country has done a twilight of the gods isn’t going to help. The Fg42 fits the profile i.e. Physically, under tube etc for der new mechanism. Polymer, non reciprocating Hk style left hand cocking lark, you can do a buffer. Why not? It’s bringing history, back.

I am saying, fluted chambers in the parallel universe of Zombie Nazis aren’t the future.

woooooo! “Zombie, Nazi… There” Bullpup like- but not a Bullpub, parallel futures, woo, woo! Etc.

Unt ze guns would looken like the Fg42 mit der futures, it doesn’t shoot cases upwarden. Lose that flash an all, without ze need for das back poopfen.

Or maybe this…

http://www.historicalfirearms.info/post/106837493047/knorr-bremse-paratroop-rifle-the-rifle-above-is

Which is sort of that.

“However, the Springfield Armory notes that it is gas-operated and roller locking. The weapon’s muzzle device is ported and the top is cut open in an attempt to compensate for the recoil produced by the the 7.92mm round.”

The stock is attached to the buffers arse end, right. So that’s another reason to keep it, can be done. Everything can be done, no? Why???

Hey look, a polymer stocked Fg42:

http://www.thefirearmblog.com/blog/2012/04/26/fg-42-tactical-take-a-deep-breath/

Em2’s auto bolt release when you pop in a mag, would be good…

It seems to resemble the ump and its carbine variant externally

two observations concerning the grossfus carbine. one if you look at the russian schematic drawing the gas piston/slide retard surface is positively controlled by the difference in height of the cutouts in the inside of the bolt, when the bolt closes it draws the piston into the fully extended position. second, the angle of the piston, provided that the the piston is the same diameter as the cartridge base will provide a closing force equivalent to the cosign of the angle, ergo, 30 degrees~86% of the force pushing on the bolt face.disregarding friction.

It honestly looks a lot like a H&K UMP45

Been smoking some funny stuff ?

I am developing a weapon system based on this design.