The M1 Garand ran great in testing, but as soon as Springfield began to crank out production-line guns a mysterious problem appeared. If the top round in the clip was on the right-hand side, the 7th round in the clip would often run askew and malfunction. Where did this very odd problem come from, and why the connection to how the clip was loaded?

In a classic example of “guns are hard” going from prototypes to production line tooling, Springfield had to figure out the problem while the War Department was busy sending hundreds of problem rifles to Camp Perry for public demonstration…

Reference source for this video:

Thanks Ian. That sort of detail is fascinating, but I don’t have an hour at a time to devote to Othias & Mae unless it’s something like the Pederson device or a gun I actually own.

Wonderful video. Thank you.

When Mr. M. mentioned this stoppage, of which I’d never heard, I hopped all over the internet looking for mention of it. Never found it — as if it never happened! Thank you very much for assuaging my (our) curiosity. I have a faint memory of reading that the Sten gun’s problems stemmed from a similar manufacturing trouble, that a mis-machined diameter cut in the chamber or feed ramp was the actual cause of the jams ascribed to faulty magazines.

It appears that stupidity never ceases to amaze me. I’ve had a few misfeeds on an air-soft K98 I recently bought (it was the D-Boys spring-powered rifle that uses cartridge cases to hold the 6mm BB’s). Every time I had a full magazine, the 4th (second to last) cartridge would apparently misfeed and jam at an awkward angle if I tried to slam the bolt home rather than let the cartridge slip out from under the feed lip by nudging it gently. Perhaps the poor machining trait applies to my situation as well?

If you could find that report it would be highly interesting. All reports on the ‘Stench Gun” (as some Royal Commanders allegedly called when told they had to give up their beloved Thompsons) problem was the magazine. I read one report where STEN gun users would go through a stack of magazines to see which ones functioned with there weapon.

This is correct. According to John Weeks, the problem was that the Sten used the same pattern of feed system as the Lanchester, which inherited it from the German MP28. It is a double row leading to a centered single-position feed. Note that most high-capacity automatic pistols today use the same system.

This feed can work perfectly well if the magazines, especially the feed lips, are carefully made and kept undamaged (no dents, etc.). It worked quite well on the Thompson and the Erma MP38/40, for instance.

But if the magazine is made rather roughly or is handled that way and the feed lips are in any way “off spec”, there will be jams.

This was the reason Sten magazines came in pasteboard cartons. To protect the magazine feed lips from damage. But only improved QC (which didn’t arrive until the Sten Mk V production run in 1944-45)really solved the problem.

cheers

eon

The workmanship (as applied to the MP38 / STEN / M3 magazines) was not decisive.

An error was made in the internal geometry of the magazine throat. And the journal was copied along with this error.

It’s funny that the Germans themselves knew about this error and developed changes to eliminate it. BUT (speaking of bureaucracy) until the very end, they continued to issue magazines of the old spec.

So quick thinking and disciplined performance by James Hatcher and one or two others saves the M1 from possibly being aborted by a press frenzy; and assistant foreman James Camel fixes it without a million Dollar investigation. If they had not done a proper job the US could have started WWII with a few thousand Johnston’s (because of the time taken to tool up) and most grunts carrying a Springfield!

Could do with some sort of app… Or, er… Computer thing, exel… To… Well see all these points: Blueprints thus, but production thus… That prevents folk from chipping off bits; shares it like with the blueprint people.

Maybe we already have these things “not sure” U.K is having problems with Ajax vehicles seemingly… Just saying, the amount of times the author has mentioned such things happening prior; has preventing it been addressed. This is aside from modern production of “test” the R51 pistol on the public, or that Boeing plane which seems great on paper; flies by computers without which it is a paperweight… Test on public; ooops 200+ die in a crash, ooops another 200… Er…

Type thing.

Watched the Johnson rifle vids again incidentally; did occur to me it may have been awhile ago when I thought longer barrels were about more rifling than pressure, and/or I was drunk.

But having done so, I still think I basically get it enough to suggest a cmmg type .223 self opening Ar via the polymer lower and a new tubular upper; just cut the tube for the down motion of the cocking handle after the “up” via the ramp. Assuming you read my prior thoughts on the subject he he.

Anyway, have we sorted the manufacturing problems alluded to in this vid via Cnc given we no longer have lines of folk looking at bits at springfield etc.

If not, perhaps the key to mass manufacture for say (pistols) is lines of folk, as oppose cnc he he. In that it would then work prior to “test on the public” I know nothing about cnc, but just putting it out there… I mean it cost Boeing far more, than paying lots of folk to say this is shit.

Maybe it has come round full circle; you know, maybe making guns is better more profitable via mass production without cnc. I mean maybe not, but how many times will the public buy R51’s etc that are tested on them.

Won’t folk buy Airbus planes etc.

I think I get the idea behind the Boeing plane; because of “electronics” what you can do is… Instead of making a mechanical part to say raise a big flap… At a certain point, by say pulling a wire, you can make a electric “thing” to say flap a wee flap like fuck to try and achieve the same affect… With any luck.

Big flap, cost 10 pound vs wee flap cost 50p… On the face of it, that seems great.

Apart from it crashed and killed everyone, if you see my point.

The Boeing 737 Max-8 has the same problem that all Airbus airliners have. A highly sophisticated, computerized autopilot that is intended to fly the aircraft at all times. Given erroneous software and/or input from flight data sensors, it does things at the wrong time and in the wrong way- like putting the aircraft in landing mode at 37,000 feet and 450 knots true airspeed.

(NB; The usual result of this is a sudden stall and loss of control, and often physical loss of wing and landing gear components not designed or built to be deployed above 240 knots TAS.)

Also like the Airbus airliners, the 737 Max-8 autopilot will resist any effort by the aircrew to turn it off. Meaning, it effectively cannot be deactivated and the aircraft cannot be flown manually.

For a non-fatal example of how this acts on an Airbus, specifically an A380, see

https://www.facebook.com/Documentaries-103110701790182/videos/air-crash-investigation-qantas-32-titanic-in-the-sky-qantas-flight-32/729631911254842/

Unlike the ABC News special, this one details how the autopilot fought the aircrew’s ultimately successful efforts to prevent it from crashing the plane.

Like every other Airbus incident of this type, the French air safety agency investigation, in cooperation with Airbus, came to their standard conclusion;

1. Airbus aircraft are perfect.

2. Your aircrews are all idiots.

3. And anyway, you are not French.

With the 737 Max-8, Boeing was not so lucky. They were up against the U.S. National Transportation Safety Board and Congress. Who, for once, actually did more-or-less the right thing.

cheers

eon

“(…)Also like the Airbus airliners, the 737 Max-8 autopilot will resist any effort by the aircrew to turn it off. Meaning, it effectively cannot be deactivated and the aircraft cannot be flown manually.(…)”

So this https://pinterest.com/pin/429108670725015465/ is not longer actual?

“(…)Airbus aircraft are perfect.(…)”

But how they can after Air France Flight 296?

“(…)cannot be deactivated and the aircraft cannot be flown manually(…)”

Also, is this not somewhat illegal? Though maybe it is legal considering that westerners have ergonomics in high disregard including using horizon working wrong way https://www.skybrary.aero/index.php/Western_and_Russian_Artificial_Horizon_Formats

Boeing’s fundamental problem at the moment is that it is no longer Boeing. McDonnell-Douglas basically killed Boeing, skinned it, and has been wearing that skin for about the last 20 years or so. Boeing was a local company; I know a lot of folks who work there. Notably, the engineers who knew the reality of things all sold their stock in the company when the coup happened, and nodded knowingly once the corporate apparatchiks moved the HQ to Chicago. They predicted everything that’s happened since, to include the debacle with the 737.

I can’t remember whether it was McDonnell or Douglas that had the corporate cordyceps infestation, but one of those companies did, and when they merged, it took over the host in short order, eventually killing the new company. Then, the idiots at Boeing brought the fungus onboard with them, and here we are.

That which is named Boeing is not Boeing; think of it as McDonnell-Douglas having bought their name, and then continuing on with their own bean-counting corporate raider policies that resulted in the downfall of the original company. Boeing effectively died shortly after the merger took place, and what’s wandering around zombie-like should no longer be recognized as “Boeing”. Whatever it is, it’s something else entirely.

Dust cover; tube upper, use that Gerat 06h lark… Ways… Someone else has already made, he he.

May have been 06; point being, tubular reciever… Cut out in it, for bolt handle; that had a dust cover solution.

Just saw that Horn rifle again actually. Jager pistol manufacture method; locking based on the horn, but backwards… Barrel tips up “hinged below muzzle” port front of chamber, sends gas to (piston) embedded to frame; gas rings etc.

Pull trigger, gas hits piston, barrel tips up into slide; breech end, delaying it thus. Jager method, that would hit a stud, inclined surface lark; slide overcomes.

Polymer/metal 3d printing, new methods of design could incorporate the old all good.

Being worried about “Terminators” my point is, they are computers; their design capabilites may quickly become better then ours. Without archives etc.

This type “in the video” of fannying around was ok, if not ideal against Germans; fellow humans. Against Robots, will (hypothetically) will we have time.

The return spring could impact on the rear of the “piston” said piece being sat at around a 300 degree angle, the piston could be loose mounted on a v shape; spring hits right side of V… He he, might be less good good than a Steyr GB or more he he. Spring “under barrel” adding to delay by slide compression, perhaps.

Anyway, all good he he.

Slide pin, mounted behind barrel tipping pin… Boing, squish… Euro 2021 on Friday… He he.

Actually forget that, seems a bit convoluted or maybe in 7.62×39… No, he he.

Be good to have some sort of “super computer” really, program it with everything anyone has ever said on here about tolerances or such…

Then when you want to make a new gun you could type in, such & such and it would say (DUUUUR! & Flashing red light.) With a point. Speed up the process of making new versions of that… Forgot what it was called, looked kinda of like the robocop pistol… Supposed to offer a pistol platform which shot flatter or such… Low bore axis…

Spring was lower… Forgot.

Hudson H9. Not having a go at it; just saying the maker of that said making it was a pain in the ass. Sure a lot of these things have been covered on here; tap tap tappity tap like… Computer program.

Take the Johnsons ejector, quite good, if the takedown method was fiddly… Basically it would probably be of benefit to firearms design if folk would have a way to try to not re-invent the wheel so to speak via what I alluded to… Some sort of (DUUURR!) Thing.

Quite.

Extractor.

Anyway, I will leave it there; but take those Johnson mags… No feed lip lark, that might help some designs; but perhaps folk just forget etc. A computer would be like… A giant brain; probably not a revolutionary concept in 2021 he he.

Life is full of little glitches like that

We’ve got a really good guy at work, but, he has this urge to change things without asking…

Probably all with the best of intentions as well.

There’s something of the Cargo Cult airstrip in a lot of projects

It sort of looks like the real thing, but it just doesn’t quite seem to work

Example would be the 1902 and 1903 Springfields, sort of like the result of a drunken one night stand between a 92 mauser and a Krag and Jorgensen, but missing some vital insights

The SA80, sort of a bullpupped AR18, but missing all of the critical know-how from Armalite and Sterling

and of course, the M60.

Funny how I know some Viet Nam Grunts who liked the Pig other than its weight. I fired a lot of rounds through them, and even from standing using short bursts they were highly accurate. Once they figured out a better way to change barrels, did away with that stupid it, the gun was okay. Kolkaris hated it because you could put the piston in backward but he was a Combat Photographer and I never saw reports of people doing that in the field if properly trained. Denmark or Norway just bought some new ones. M-60E series became quite handy. The SEALS use chopped off M-60s in Viet Nam and are not people to use weapons that will get them killed. And the 1903? What was the specific complaint other than the original bullet design?

Denmark bought new M60s to replace their aging MG42/59 GPMGs. I don’t remember all the contestants, but FN MAG was certainly one of them. MG42/MG3 (whatever they would be called) were not included I believe, since the production line for them does not exist any more.

I’m still in awe of the fact that they did that, TBH. None of the really major fundamental issues of the M60 were addressed by the new version, and I’m eager to see what happens when they run out of money and maintenance time on those.

M60s can be kept up and operational; all you have to do is throw money at them, and replace the parts once they start wearing out. And, due to the composite nature of that receiver, you’re doomed to treat it as a disposable wear item. In my experience, you were lucky to get 10,000 rounds or so out of them before the rivets loosened up and the thing shook itself to death. Maybe even less…

To my mind, the M60 is just not a very good weapon. Too much maintenance required, too fussy to work with, and way too fragile. About the only way to really “fix” them is to do what the US Army finally did, and pull the tripod out from under it and put a new gun on top of it…

The Danes, after all, are the same folks who brought us the Madsen LMG. I suspect that there may be a bit of a national tradition of idiosyncratic MG procurement issues there, stemming from some inexplicable national madness. As my Norwegian friend once said about the Danes, you just can’t understand them, and you’ll save your sanity by not trying to.

DISA still makes excellent tripods, tho… Can’t fault that, at all. Of course, that tripod was originally built to go under the Madsen LMG, soooooo…

The problem with the M1903 was that early production receivers with only a single heat treatment tended to be brittle. They could literally shatter like glass during firing. When a double heat treatment was introduced, the problem was solved.

See Hatcher’s Notebook;

https://www.tngun.com/wp-content/uploads/Hatchers-Notebook.pdf

Then-Col. Julian S. Hatcher was a member of the investigating team at Army Ordnance that determined what was wrong and how to fix it.

cheers

eon

Hi Lloyd,

If you search for anything about Lewis guns and, the German FG 42 paratroop rifle on here, s well as the M60, you’ll find comments from Kirk, who had extensive experience maintaining and teaching the M60

He makes a very clear and convincing case for the M60 design team not understanding the design.

A couple of examples would be

1) the inclusion of a supplementary spring behind the striker.

On the FG42, this provided extra impetus to the heavy gas piston and striker assembly, to allow reliable ignition in the closed bolt semi auto mode.

The M60, doesn’t have a closed bolt mode, the spring is meaningless, but the design team didn’t understand that.

2)The simplified machining of the M60 bolt, compared to the FG42 and Lewis,

This resulted in significant peening on the tower from the gas piston that held the striker, and operated the locking and unlocking camming.

Kirk found that he had to do significant amounts of stoning to get rid of burrs after even short use of the guns, to get them back into useable condition.

Those problems are just not present on the M60’s direct ancestors

The case for the M60 design team not understanding the design is very convincing, even just on those two points.

Who is Kirk and where is all this burring mentioned? If it is Kolkaris he was dealing with very used guns in less than hospitable areas (South America et al). Just like the M-16, lots of complaints by a minority yet it worked, problems worked out, and killed the enemy, kept in service thru Iraq.

“Who is Kirk…”(C)

Kirk is a certified M60 operator with hands-on experience.

Who, nevertheless, has a psychological trauma caused by the fact that he was given a defective machine gun as a child.

No offense, Kirk? 😉

Kokalis probably forgot more about running machine guns of all flavors than any of us know.

And, if you don’t know about the burring issues with the M60, my guess is you never served as a gunner or an armorer. I did both, and the friggin’ thing beats itself to death at the front of the bolt cam track and on the op rod tower. If you’ve never seen that, then you’ve never taken one of those guns apart after any real usage–In my experience, there was always work for the stones after even a single belt or maybe, if you were lucky, two.

The M60 is an utter POS churned out by idiots that had no more clue about the weapons they were copying than your average trained monkey. They could have gotten all of the German TDP for the FG42, and they could have even asked the guys who designed it why they did what they did. They did not bother, and produced a product that was nighmarishly difficult to keep in service.

Trust me–I know whereof I speak, having spent a considerable chunk of my career trying to keep those pieces of shit operable enough to defend myself and my guys with. If the Army hadn’t have changed the rules about what constituted “combat readiness” sometime in the mid-1980s, then there would have been massive scandals about the M60 in Congress, because the readiness rates on those things were damn near zero between about ’88 and the time when they finally got off their asses and replaced them with the M240. There were entire years there, where I had no more than one or two guns out of a company complement of 9 up and running, and there was nothing to be done about it because the guys at 3rd Shop maintenance didn’t have the budget to do what needed to be done and code out the receivers.

The M60 is a machinegun only by courtesy; what it really is would be a loose assemblage of parts moving in formation which really do not want to be a machinegun, and who are constantly trying to beat themselves to death in order to avoid that fate. There may be worse weapons that have been procured by the US military, but as far as I saw during my 25 years, the M60 took the friggin’ prize for that dubious honor.

So another rant about the M-60 which was just repurchased by the Danes. Kolkaris was an Army Photography who may have done some combat photography who then attached himself to Soldier of Fortune Magazine. He became a know- it- all curmudgeon traveling on SOF dime primarily to South America to deal with worn-out weapons. He became a Gun Magazine Writer, not, I believe, a weapon’s developer. Funny how some Viet Nam Vets of my age were not as dismissive as you are. And Funny how the SEALS made good use of them. It is easy to rant on the Web. So tell me, how many rounds have you put through an M-60?

You demonstrate an astonishing level of arrogance and ignorance, which I should not be surprised at. You don’t know much of anything about the weapon, or about Kokalis. You can’t even spell his name right.

Peter Kokalis may have been a combat photographer, but that does nothing to lessen what he knew and did with weapons. The El Salvadoran troops he trained and assisted down there during their war knew what he did for them, and what he taught them–Which was how to keep the guns up and running. The SF guys I knew who were down there on the training teams knew what Kokalis was doing, approved of it, and considered him a subject matter expert on the guns. He wrote for many other publications besides Soldier of Fortune, and I’ve yet to see anyone refute or criticize what he had to say in much of anything.

Peter Kokalis earned his respect from the community the hard way. What have you ever done besides misspell his name, malign his reputation, and talk shit about things you’re in total ignorance of?

I would strongly suggest you back off before you find yourself in a state of embarrassment. I would be more than happy to school your stupid ass on the multitudinous flaws of the M60 when I have more time on my hands, but if you want to save me the effort (and your own embarrassment), have a look at the search function. I’ve gone over it in voluminous detail, and your childish and ill-informed insistence that it is even a vaguely serviceable weapon does nothing to enhance your credibility.

There are reasons that the Rangers and Marines worked behind the scenes to get rid of that POS back in the 90s. It’s a travesty that they had to do that, but it is more than indicative of what an utter POS the weapon is that they worked together to back-door the M240 into the system–Not to mention, the fact that once they’d done that, the M240 demonstrated such massive superiority that the morons running procurement had no choice but to acquiesce to the entire affair without ever running another multi-billion dollar procurement racket.

That’s how bad your beloved M60 was–It got back-doored so thoroughly that they couldn’t even keep ahead of a bunch of company-grade Marine and Ranger officers running an insurgent campaign behind their backs to replace it with excess guns originally procured as coax weapons for the M1 and Bradley. I can’t think of any other case that’s even remotely similar to that, anywhere in US military procurement history.

Which is, in and of itself, damning evidence for the quality of the M60.

Proof of all your back door information. Why are SEALS photographed using an M-60. You claiming I am arrogant is the kettle calling the stove black.No one has ever been able to explain to me why Kolkaris did not obtain another job in the military if he was so desiring more experience in combat arms. Have a nice day arguing online just to argue.

Lemme see if I can sum this up… On the one hand, we have Peter G. Kokalis, a source who is considered by many to be authoritative years after his death. A man who wrote for a multitude of publications to include Small Arms Review, Shotgun News, and others. Someone who was trusted enough by the El Salvadoran Army and the US Special Forces to provide intermediate maintenance support to the El Salvadoran armed forces when the US could not or would not support the “sainted” M60. They thought highly enough of his work on their behalf to issue him official commendations.

On the other, we have Loyd. An internet troll whose fundamental illiteracy and stupidity knows no apparent limits–He can’t even spell the name of the man he’s maligning without screwing it up, and he then cites “pictures of SEALS with the M60” as some sort of closing argument.

Dude, you’re a pitiful excuse for even a troll: You can’t even troll properly; refutation of your blathering is so easy and trivially accomplished as to make fishing in a barrel with high explosives look hard. I almost feel sorry for you, because you obviously don’t grasp how low your actual IQ and knowledge of this field actually is.

Which probably means you are or have worked for US ordnance in some capacity.

“The M60, doesn’t have a closed bolt mode, the spring is meaningless, but the design team didn’t understand that.”(С)

The fact that You do not understand the purpose of this spring does NOT mean that the designers of the M60 are idiots. 😉

The firing pin spring is needed to stabilize cyclic rate and survivability of firing pin.

There is a similar spring in the Negev and in others.

“…stabilize cyclic rate and survivability of firing pin.”

You’re gonna have to explain to me how that works, because I’ve got not a single ‘effing clue how that spring could perform either function.

I’ve also observed M60s in the field which fired ungodly amounts of ammo without that spring in place, with no ill effect or change to the cyclic rate. So…? Please explain that, and if you could perhaps point to the engineering work that validates your position, I would appreciate it.

Oh, and by the way… The opinions I have on that matter are not due solely to my own experience and observation. They come from a number of sources, one of which was a long-service small arms maintenance warrant officer with extensive experience on the gun, and a guy who was engaged with actual, y’know… Engineering work on the M60. His take on the original design is mostly unprintable, and not once have I ever heard him say that that spring performed any function whatsoever. So, if you’re right, and you can back it up, I’d appreciate the citations.

The fact that you’re saying this pretty clearly indicates that you’ve got not a fucking clue what is going on in these weapons. In the Negev, the bolt is basically a Galil bolt, and that firing pin spring is there to do the same thing it is doing in the Galil–Stop the firing pin from bouncing and detonating the cartridge before it is fully locked. The firing pin spring is in front of the shoulder on the firing pin. The one on the M60 is the opposite, indicating that the idiot who copied the FG42 did not understand that it was there to assist the firing pin in semi-auto fire…

Please refer to this illustration of the Negev’s parts for actual, y’know… Facts:

https://www.gunco.net/threads/feed-lever-design-in-negev.36704/

Specifically, you want Figure 3, part numbers 34 and 35.

As I would say to any of my students as an instructor when they tried to sharpshoot me, you’re showing your ass. If you want to be taken seriously, you really need to provide us with the citations for your assertions.

For the ’03 Springfield project we really need to go back to the trials where the Krag & Jorgensen was adopted.

The first patent for the Krag and Jorgensen shows an en bloc charger, useable with the Krag adopted by tje kingdom of Denmark.

What was the purpose of the Springfield project following the Spanish-American war in Cuba?

It was to provide a rifle capable of charger loading!

Bear in mind that for 10 years or more before 1903, Mauser rifles had been available with stripper loading

They had also been available with controlled feed and double column magazines since either 1894 0r 1896, along with minimal cartridge head protrusion from the chamber

Eventually we reach the 1898 Mauser, with inner collar breeching and gas deflecting shrouds

What did the 1902 Springfield have?

A single column mag and a magazine cut off, with massive and unsupported case head protrusion, along with an over length case, that under performed at anything more than 100m

1903, added a double column magazine, and still represented the deformed results of a drunken one night stand between a Krag and a Mauser 96, with worse breech design than either.

It also carried over the spongy and fragile jointed striker from the Krag.

It’s one saving grace, at least it was short enough for general use without a special carbine version.

The Springfield design team and Theodore Roosevelt, had studiously ignored almost all of Mauser’s design experience from the previous 13 years.

Regarding the metallurgical problems, the metallurgy hadn’t changed from the Krag, it was plain and simple state sector inertia and incompetence.

The bullet choicesas well, both the 03 and 06 bullets had the same ballistic coefficients, it’s just that the 03 had a higher MV.

Both were far out classed by French Balle D and .303 Mkvii,

Butcher’s notebook is clear on that point, but he is not consistent

He then has the nationalistic insolence in his description of the Lewis gun, to describe it’s difficulties in being adapted to the “vastly superior. 30-06”

With reference to Hatcher’s earlier (and more honest) chapters, it would be interesting to know how and where the .30-06 might possibly be “Superior”, and, if so, “Superior” to what?

At the time,.30-06 was superior to both the 7.9 x 57 it was derived from and the 0.303in in range and accuracy, which was the dernier cri’ of rifle cartridge design in those days.

Its main problem was that its 7.62 x 63mm cartridge profile made it more difficult than average to run through a machine-gun as opposed to a manual-repeating system like a bolt-action rifle. This was the main reason for the development of the 7.62 x 51mm NATO, which was developed from the .300 Savage, rather than the .30-06.

As for the Lewis Gun, Hatcher considered it overall inferior to the Benet-Mercie’ M1909 Machine Rifle, which of course was really just a Hotchkiss Portative in .30-06. It’s a tribute to how well designed the Hotchkiss system was that it “ran” quite well in .30-06, having originally been designed for 8 x 50mmR Lebel; it’s hard to imagine two cartridges with more radically-different profiles.

It’s worth noting that Hotchkiss-pattern guns were used in both world wars as first line MGs. For instance, most of the Japanese HMGs and etc. prior to the Type 99 were based on the Hotchkiss system, and even the 99, though nominally a ZB26 type like the Bren, was really more of a Hotchkiss/ZB26 hybrid.

As for the Lewis Gun, it gave rise to the FG42 and the M60. As the old engineering saying goes, if nobody else does it that way, there’s usually a very good reason.

cheers

eon

Hatcher made very clear, that the 150 grain .30-06 gave a significantly shorter range for laying down a machine gun barrage, compared to French 8mm Balle D, or .303 Mkvii.

If you run the figures, it turns out that 8mm Lebel Balle D, was ahead of .30-06 in all ballistic criteria at all ranges beyond 100m

.303 Mkvii took a little further to overtake the. 30-06.

Even load a .303 Mkvii bullet down to .30-30 Winchester muzzle velocities, and it will still exceed the ballistics of .30-06 beyond 800m!

Hatcher used the Swiss 180grain boat-tail target bullet to develop the .30-06 M1 ball, which corrected the ballistic short comings of the original. 30-06, but was unpopular because of its heavier recoil, and it exceeded the danger zones around practice ranges.

The M2 ball returned to the performance of the original .30-06 – a big, long, loud, under-performer.

Hatcher was very clear on this, yet, he still lapsed into unsupported nationalistic jingo about the “vastly superior.30-06”

Gee, if the Springfield was so horrible, why was it successful? I have one, it does not shoot like a rifle designed by a drunk. I think you have a bit of bigotry going on with over-the-hill comments.

The 1903 Springfield was not successful in any competitive sense,

It was adopted by a bureauctic institution, and those bureaucrats stuck with their (IMO poor) decision.

It’s very clear that the design team for the 1903, failed to understand many of the details of the Mauser designs that they were trying to copy.

In your English Opinion just looking for an argument. The Springfield worked just fine even in WWII when hundreds of thousands were given (1903A3) to our allies and the Marines used on Guadalcanal. Some Old School Marines did not rust the Garand, modified Springfield to accept BAR magazines.

Denmark bought the M60E6. I’ve shot it in the Danish Home Guard a few years ago.

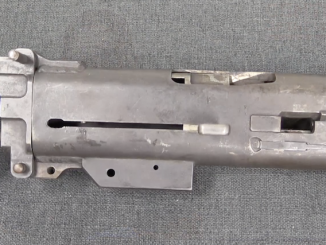

I’m going to guess that the nub on the right side of the receiver was helpful in directing the 7th round into the chamber, if the clip had the first round on the right. Ian didn’t specify the nature of the “jam”, but FTF seems most likely.

Back in the day when I was buying L1011 Tristar components for the worlds favourite airline, I had a problem with a supplier who suddenly experienced a 98% failure rate on a specific component. Turned out they had a newby on the lathe who followed the drawings, as he should but he couldn’t get it right. Turned out the “old bloke” before him and who had been shucking out thousands for 20 years with no problem at all had just retired not bothering to tell the new one (or the drawing office/management that the gobbleygook on the workshop blueprint scribbled around the edges actually meant’ something (as in, don’t do it this way do it that, don’t cut x thou off cut y ) but only to the old git who had just retired. Took month to sort out and big delays on our maintenance line

Tribal knowledge, as they say. It’ll be the death of us, because nobody thinks it has any value and has even less idea how to capture it.

“…design team for the 1903, failed to understand many of the details of the Mauser designs…”(C)

It is interesting.

Truth.

And You can wonder where exactly this happened?

Or is it, as with the M60 firing pin spring, You just did not understand the manual? 😉

The person demonstrating the lack of understanding here would be… You.

Your assertions about both weapons are in fundamental error. One, you do not demonstrate any understanding of how the M60 actually works, nor do you seem to grasp the fact that the M1903 was based on the earlier versions of the Mauser, specifically the 1893 Spanish model.

Other people have laid out the differences and issues, and I’ll quote one of them because I’m not the primitive weapons expert I should be:

“From a pure design point of view, the ’03 is inferior to the original Mauser design.

The Mauser ’98 design is one of those rare “perfect” designs. There is NOTHING that can be done to “improve” the ’98 design, and all changes since Mauser invented and perfected it, are to allow it to be made cheaper or faster.

When the ’03 was designed, the basic Mauser design was modified to what the ordnance department thought an American service rifle should be.

In order to do that, they actually produced a design that was inferior to the deceptively elegant ’98.

The Mauser’s bolt lock is a very robust, large pin with a strong spring, both of which are completed covered by the bolt shroud. These just don’t give trouble, no matter what.

The ’03’s bolt lock is a tiny, flat piece of steel with a very tiny spring, both of which are mounted on the side of the bolt shroud, and completely exposed to dirt, grim, and weather.

They fairly regularly gum up, rust, or wear and fail to properly lock the shroud.

The Mauser extractor’s front end rides in a dovetail groove. The harder the bolt is pulled, the tighter the extractor grips the case head.

The ’03 extractor rides in a non-dovetail groove, and can slip up out of engagement with the case head.

The Mauser’s safety is a one piece chunk of milled steel, and is easy to disassemble.

The ’03 uses a multi-part assembly with an exposed spring and plunger and requires tools to disassemble.

The Mauser uses a light one piece firing pin with a small, light cocking piece.

The ’03 uses a heavy multi-part firing pin assemble, with a massive, and more or less unnecessary cocking piece grip knob.

The Mauser uses a simple, strong ejector/bolt release assembly.

The ’03 uses a smaller, weaker ejector, and the complicated magazine cut off/bolt release. To be fair, the cut off concept was still valid in 1903.

The Mauser receiver is deceptively simple, and has a very strong rear bridge.

Although hell-for-strong, the ’03’s receiver is complicated, and has a weaker rear bridge.

The Mauser stepped barrel is easier to bed, and the bedding system at least potentially offers better accuracy than the tapered ’03 barrel and it’s tendency to “wedge” in the bedding.

The Mauser stock, and particularly hand guards are stronger than the ’03, and offers a better shooter’s grip than the skinny straight-grip ’03 stock.

Overall, the ’03 was superior for the quality of workmanship. The Mauser suffered from manufacture during loosing wars, and quality ran from excellent to “last ditch” poor.

The ’03 was always uniformly excellent.

The Mauser sights were too simple, and should have had a windage adjustment. Although simple and fool proof, the sights prevented the rifle from reaching it’s full accuracy potential.

The ’03 sights were too complicated and fragile, and were incapable of repeatable settings since there were no “clicks” or other positive means of adjusting them.

In fairness the ’03 sights were state of the art in 1903.

In sum, the statement that the Mauser was a battle rifle, and the ’03 was a target rifle, does have a certain truth. This is understandable, since the period from around the turn of the century up until the era of the M-16, was the era of the “target shooter’s” in Army ordnance.

They insisted on accuracy almost to the exclusion of all else. The well-documented development history of the M1 Garand gives fascinating insights into this attitude. There was strong resistance to the M1 because it wasn’t accurate enough, and would lead to the old horror of the “target shooter’s”: Soldiers wasting ammunition.

In the 1903, they got the target rifle they always wanted, and it did serve very well through two world wars, the “banana wars”

and into Vietnam.

It was superior to the Mauser only because of the quality of materials and workmanship.”

I’m going to criticize this summation, mainly because I think the writer has somewhat rose-colored glasses on when he discusses “quality of materials and worksmanship”. The Germans never had the heat treatment issues that the US did, mostly because they actually used pyrometers from the beginning, and did not have the casual approach to heat treatment by eye that the US used.

As well, there’s the not insignificant fact that the 1898 model that the Germans settled on was a more refined model than the one used as the basis for copying the Springfield. It was what it was, and that was not the “ultimate Mauser-based bolt-action combat rifle”. That might have been the Arisaka Type 38, which was highlighted by P.O. Ackley as the “strongest action ever tested” by him. Established, I might add, by destructive testing… The Type 99 came in second.

Another person you pick and chooses his sources just to argue with people. Did Springfield do an excellent job in various conflicts? Yes. Will some people still claim the Mauser is somehow better? Yes. Does that make you an expert who can then disparage others who disagree with you? No, it does not. Argue with the Danes about the M-60 as to why they choose recently such a horrible MG according to you. And changing the subject to the Arisaka? That rifle is legendary for its bolt strength even over the Mauser, which is why so many were modified in the U.S. later on. Have a nice day!

The Danish soldiers who get to use the M60, may well have a different opinion of the gun than the bureautwats who chose to buy it, and who have no actual skin in the game.

American arms exports are a very political matter

It’s therefore a fair question to ask, whether the performance, serviceability and lifetime cost of the gun were prime criteria, and even there, big mistakes can easily be made.

Or, whether kickbacks or some political quid pro quo was the primary decider.

Incidentally, the bolt lug design of the Arisaka isn’t exceptional in either shear or bearing area.

The strength of the design during blow up “tests”, has to be found elsewhere

The same thing is true of the remarkably resilient Carcano.

A Mauser 98 has quite modest lug bearing and shear areas, yet it is still a prime choice as a basis for rifles in some very big, high pressure cartridges, including. 460 wetherby.

The answer in all three examples is the careful design of the breech, to limit the chances of high pressure gasses reaching the area of the receiver ring that has been bored out for the locking lugs, and which offered a larger surface for gas to act upon.

An area which the designers of the 1903, failed to understand.

People can be really good at coping with foulups before the newspapers find out. I hope Walter Campbell was well rewarded for his work.