In 1920, Fritz Mann of Germany patented the idea of cutting a shallow ring in the chamber of a pistol as a delaying mechanism. When fired, a cartridge case would expand into this groove, thus requiring more time and energy to push the case out of the chamber and effectively delaying opening. This allowed Mann to reduce the weight of the operating parts of his model 1920 semiauto pistol in .25ACP (aka 6.35mm Browning). The gun was designed to be as small and as light as possible; a true pocket pistol. Thousands of them were made in 1920 and 1921, although he gun failed to see long-term popularity. For more information, I recommend Stefan Klein’s article on Ed Buffaloe’s web site:

Related Articles

Book review

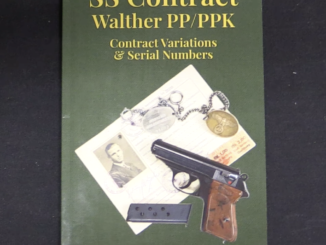

Book Review: SS Contract Walther PP/PPK

I have done some videos previously with Tom Whiteman from Legacy Collectibles – mostly ones about his area of specialty; German WW2 handguns. Well, he has now published a reference book compiling more than 20 […]

Commentary

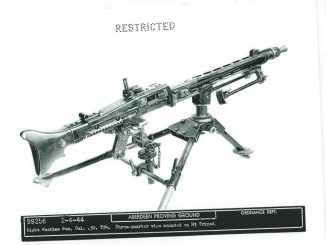

An American .30-06 MG-42, and GPMGs after WWII

The perk for $100 Patrons is choosing a gun they would like me to find and film, and one such Patron (Mark) expressed a curiosity about US testing and lack of adoption of an MG-42 […]

Patent drawings

Bergmann 1894 – No.1 Pistol

As Theodore Bergmann and Louis Schmeisser embarked on the process of perfecting and improving their production pistols, they used a numbering system to identify the different models that were made. There are also model years […]

Seecamp pistol; https://en.m.wikipedia.org/wiki/Seecamp was maybe based “probably” on this, not that I knew about this Mann pistol prior to this video… Clever idea, really… Especially in 1921.

Wonder if Nitinol could be used (I know I say that about most things) but, simply… I.e. A ring on the case, to go into a hole for said “ring” in the chamber… Bang! = Heat = Niti swells = Chamber fills = slower opening. Maybe try it with .762x33mm carbine tied to a fence, pull a string; to depress the trigger. Pop over have a nosey.

Flat ring; swells with heat… Flat in = Swelled out.

Albeit it needs “the niti” to cool a bit to de-swell… But maybe there is a medium I.e. As pressure blowing it out/extractor pulling on the case… So it might just provide a WEE! Stretch (as per normal chamber ring delay; but with increased filling of chamber) but then via said forces give way… The WEE! bit, I emphasise; because it is all over quick- bullet exits barrel so maybe it is wee enough, obviously with that depends how quick the niti actions… Maybe combine both; brass chamber ring as per, backed up by niti (give the nitinol a chance to expand) might work… Be good if it did.

It would really; Point being negate the need for mechanical delay/locking, the round does it itself.

If it works in a .30 m1 fiddle some more; might work in .223 etc, even with more chamber rings/niti rings/brass/normal chamber rings. Ways… Probably anyway, 1921 100 years ago; pretty cool!

Thickness/angle/setting of niti ring, would be to assist de-swelling without temp cooling, much… Anyway all good.

Theoretically I am saying that could work; on the premise that WEE! extra expansion vs Brass, is enough. If the timing can be made right; which maybe it can’t be, I don’t know.

Anyway I won’t go on, and on he he.

I will honest, stop now; but I put it to you niti apparently must atomically change. 100,000psi it just must; thus I am saying, that is the delay.

Be great though as a mk108 type cannon, with niti detonation and this type of round we could increase it’s destructive power ten fold; high pressure, which is what… We may need for, robots.

They have the advantage; they don’t bleed etc.

Can be addressed.

100 fold ideally; seperate subject under the terms of shutting up prior, I am unilaterally allowed to rant about anti robot measures which may or may not be needed he he.

“(…)Point being negate the need for mechanical delay/locking, the round does it itself.(…)”

You do not want need for locking? Then use HUGHES LOCKLESS cartridge https://www.cartridgecollector.net/556-x-30-hughes-lockless

Pah, thats rubbish “for once” we need big fuck off terminator rounds. Mk108. At speed, with more power; but with a cheap gun.

Yay!! He he.

“(…)mk108 type cannon(…)increase it’s destructive power ten fold;(…)”

Unless it is intentional show of disdain it should be MK 108. I do not get how you would to get desired result, remember that it used Minengeschoß which already have high ratio of HE filler mass to overall mass of shell. How your solution can make that ratio higher?

Niti detonators: round is detonated as per now but, its quicker no mech, niti change detonates primer, then round is armed and spat out under a higher pressure than the stubby barrel via thinking of the above as being in the projectile & shell more gas.

Minengeschoß; longer barrel with mk108 action I mean.

Cheap. If we ever fight migs, with eurofighters.

The best design will actually be the mig17 as they will be all dead at the cost of trillions in days.

Get it patented Chatty 🙂

“(…)ring on the case(…)”

Are you sure that such case, i.e. composed of vastly different materials could be stored as effortless as classic one? Also what about price, note that cases are often ejected and thus used once.

Fire them quicker.

Tap, tap, tappity, tap… Hmmm, he he.

Can see some problems with that, he he.

See also Detonics Pocket 9

“Seecamp pistol; https://en.m.wikipedia.org/wiki/Seecamp was maybe based “probably” on this(…)”

From geographic point of view and year point of view Kimball Arms .30 Carbine is closer to Seecamp design http://www.mythicarmory.com/kimball-arms-30-carbine.html

So steel-cased cartridges would not be indicated for the pocket Mann.

I don’t think the .25 ACP ever had a steel case.

I do not know about steel but municion http://old.municion.org/6_35/6_35.htm shows aluminium cased examples, naboje https://naboje.org/node/3360 what is apparently non-brass case (see 1st image from bottom)

https://naboje.org/node/3360

It is nickel-plated (possibly cadmium) brass.

High pressure cartridge.

Colt made a 1911 in 38 special using the ring delayed system.

Interesting. Do you know why? .38 Special should be easily handled by Browning’s tilting barrel system. Just an experiment?

https://revivaler.com/colt-m1911-gold-cup-national-match-38-special/ describes blow-back operated 1911 for subset of .38 Special cartridges and says that

the advantage of this being that the barrel could be kept in alignment throughout the cycling of the action. The disadvantage of this was that the magazine needed to align the cartridge at as close to that barrel line as possible.

nitpick: Wrong flag in the thumbnail. Since 1919 black-red-gold was the flag of Germany.

A perfect example when a competent mechanic thinks that there are no secrets in machine gun building. 😉

Technically, an almost perfect design, while completely inadequate for its purpose.

Due to the tiny grip of this pistol, it was almost impossible to hit anything on purpose.

And due to the overall small size and wacky ergonomics, it was very easy to accidentally hit yourself.

In addition, he also had the habit of biting.

And the field strip is limited to the removal of the barrel. This is enough for service.

did’nt the hi standard t3 pistol /experimental/ use the ringed chamber?

Walther 9 of the same era designed in the due course was slightly heavier but shorter than this .25” pistol… This means there would be no hopefull market chance… But the delaying concept seemed hopefull… For somewhat heavier caliber…

The machining cost seems nearly equal with standart blowback models if the one piece frame was not made of investment casting method which was unpopular at that time…

IMHO…

“(…) delaying concept seemed hopefull… For somewhat heavier caliber…”

Mann later developed automatic pistol chambered for 7,65 mm Browning or 9×17 Kurz cartridge. https://unblinkingeye.com/Guns/Mann765/mann765.html

advert say it is touted as more elegant and light than well-known 6,35 mm automatic pistols [of its’ era]

“(…)somewhat heavier caliber(…)”

If you need automatic pistol with chamber-ring-delaying scheme used and using heavier than 6,35 mm Browning cartridge get http://gunrf.ru/rg_pistol_PMM_eng.html

Somewhere I read about a FLUTED chamber for delaying blowback. The flutes are blind, i.e., they stop short of the cartridge mouth and thus don’t admit gas to the chamber. As with the ring method, the delay is caused by the case expanding into the flutes during peak pressure, and then springing back as pressure drops. (Good old brass will do that.) Thus the stresses on the case are longitudinal rather than radial, and might (he theorized hopefully) be less likely to cause separations.

The flutes are extremely shallow, and I have to wonder wonder how long they last.

The Heckler & Koch HK4 used the type of flutes you describe in its 9 mm kurz (.380 Browning) barrel. But they were not at all shallow and also rather wide.

https://unblinkingeye.com/Guns/HK4/HK4-12/ChamberGrooves.jpg

https://html2-f.scribdassets.com/1pstzd4j9c2argpy/images/1-4d3fc84e6d.jpg

Later, this principle was applied to the 9×18 PMM cartridge.

Not the best solution for the target pistol.

Simple recoil or short barrel throws are more accurate.

The Kimball automatic in .30 Carbine used “rings” or “rills” in the chamber walls to achieve a form of friction-delayed blowback. It was not a success.

Longitudinal fluting was used by Heckler & Koch in their roller-delayed recoil-operated weapons such as the HK 91 to reduce primary extraction drag, by literally “floating” the case on a layer of blown-back gas as the action cycled.

This tends to increase RoF in automatic fire, and would probably be useful in weapons intended for very high RoFs, such as automatic AA guns or aircraft cannon as well.

The first rule of AA or AtA shooting in the jet age is, you only have a couple of seconds to hit something, make them count.

cheers

eon

There were many different.

http://hk-manuals.s3.amazonaws.com/files/Misc/Other/Fluted_and_Annular_Grooved_Chambers_in_Firearms.pdf

And they work in different ways.

As a recoil retarder, this is only suitable for cartridges with a relatively low pressure and a durable case.

As with any system that is critically dependent on the quality of the ammunition, this cannot reliably work with commercial ammunition.

That is seemingly rather slow .223 Remington, unless it was proofed from a 16″ bbl?

A fascinating little pistol – with the emphasis on little. Is there any indication as to how popular such small caliber pistols were (there certainly seems to be a number of these designs)? Given that these seem to be quite ineffective and even had ‘modest presence’ e.g. hardly a strong deterrence if flourished or fired for effect.

“(…)how popular such small caliber pistols were(…)”

6,35 mm Browning was popular cartridge in Germany during interbellum. For example according to http://historypistols.ru/blog/pistolety-pod-unitarnyj-patron-avtomaticheskie/malenkij-mauzer-mauser-werke-1910-1914-1934-g/ there were made 330000 examples of 6,35 mm Mauser 1914 automatic pistol and this one of numerous models, see

http://www.vestpockets.bauli.at/archiv/archiv.htm

Even the bigger ORTGIES automatic pistol was available in 6,35 mm https://unblinkingeye.com/Guns/Ortgies/ortgies.html

After looking at Ed Buffaloe’s article I am glad to have this video and see how the innards were actually put together. I think this is a fascinating design — a solid frame in one piece with all the working bits inserted from front, back, and bottom. Even aesthetically the shape is intriguing: the sloping surfaces rising to an almost-apex at the top strap, the huge curve for the web of your hand, a trigger guard that can double as a knuckle-duster. Many thanks to Mr. M for bringing this to us.

“…the huge curve for the web of your hand…”(C)

It is in this place that they bite.

“Everywhere I hear the sound of marchin’, chargin’ feet, boy

‘Cause summer’s here, and the time is right

For fighting in the street, boy”

Given what was going down in the streets in Germany in the early Twenties (The Allies thought it was appropriate to allow the polezei to carry machine pistols) with gangs to yeggs from both the Left and Right battling it out daily, we can quote an old Tammany Hall operator, ““I seen my opportunities and I took ‘em” (George Washington Plunkitt)Hey, the market was there to be filled, The gun looks well made and finished, as you would expect from a German gin make of the period. I like it ! I may well have bought one back in the day, Dad, can I borrow the time machine, tonight….

PS: OK, I promise to avoid funny little ex-corporals with tooth brush mustaches

Substitute “gun” maker” fi=or “gin maker”, although the idea of German made Gin sounds interesting. Ian, can we get to try some on your next Q&A

Perfect pistol to be smuggled into a Male or Female Prison.

Here’s a totally disassembled Mann: http://www.vestpockets.bauli.at/archiv/mann1p.jpg

The bolt is hanging up on the sear, which is pinned into the frame inside the very back of the web strap. (Perhaps pulling the trigger releases the bolt, like a Carcano rifle?) I believe the scallop cut on the bolt acts also as disconnector.

Here’s a blog thread about it: https://thefiringline.com/forums/showthread.php?t=310658&page=2

Wherein you find other cleverness, such as the magazine return spring and the trigger return spring were one, really odd, stirrup-shaped spring.

Mann also designed a 7.65 after this one went out of production. Also very small with an odd magazine release that uses the same lever as the safety (Up is safe down is fire and way down ejects the magazine). It also used the annular groove system.

https://unblinkingeye.com/Guns/Mann765/mann765.html