Nick Crawford contacted me after seeing my recent video on the Tariq pistol RIA is selling this weekend, to mention that he’d had the opportunity to poke around the factory where those pistols had been made. I asked Nick for details, and he generously obliged with the following writeup of his experiences:

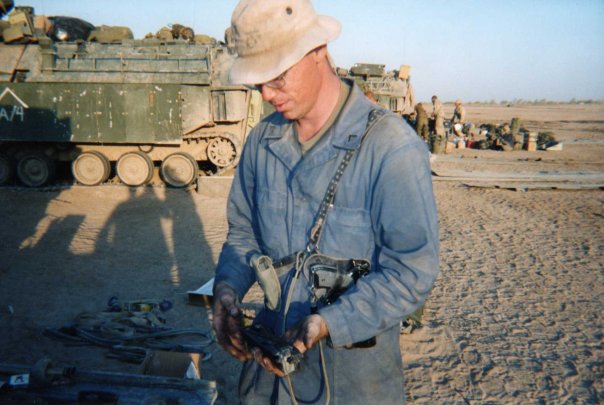

I watched Ian’s recent video on the Tariq pistol with great interest as it brought back memories of my experiences with the Tariq. My personal experiences with the Tariq pistol were during my 2003 deployment to Iraq. I served as a member of the U.S. Marine Corps Regimental Combat Team 1 and participated in the invasion and initial occupation of Baghdad. After two weeks in Baghdad my unit began our retrograde to the city of Al Hillah, about 60 miles south of Baghdad. It was at Al Hillah that I first examined the Tariq.

Once in Al Hillah, our company was quartered at a factory complex that manufactured the Tariq pistol. This complex included bulk fuel storage, warehouses and vehicle storage areas. The actual pistol factory was about 15,000 to 20,000 square feet in size and part of the larger overall industrial complex. Prior to the invasion the complex was under the control of the Iraqi Army. The factory was looted by civilians during period the Iraqi Army left and U.S. forces arrived. This was a common occurrence with other sites we had encountered previously. While in Baghdad we were quartered briefly at the UN Assistance Mission and it had also been looted prior to our arrival.

After being at the industrial complex a day or two a fellow Marine approached asking if I wanted to see something interesting. The Marine then handed me four pieces of metal and asked if I could identify them. The first ones I examined were not a complete pistol but two slides and two frame assemblies in various stages of completion. Of the two slides I examined, both had Arabic characters and the word “Tariq” in English on the slide. The state of completion was approximately 60-80% for both slides and frames. The frames were not identical as one was larger than the other. The “Tariq” marked slides seemed to fit the larger frame. As a long time collector the overall design looked very similar to the Beretta 1951/Helwan pistol. The smaller frame was not recognizable to me at the time. The overall completion of the smaller frame led to an educated guess on my part. I told the Marine the larger pistol was most likely a Helwan copy and the smaller frame was most likely chambered in .32 ACP or .380 ACP with the possibility of 9mm Makarov. Only after returning to the United States did I learn the smaller frame was a copy of the Beretta M70 model.

When I asked the Marine where he had gotten them he pointed to the building behind us. It seems that for the last 2 days I had been sleeping beside a firearms factory and I wasn’t even aware. A group of us walked over to the building and looked through the windows. The windows were mostly broken out and allowed for a good view of the interior. The scene reminded me of photos taken of the Walther factory by US troops during World War Two. The factory had work benches arraigned along the outer walls with various machine tools in the center. The benches had pistols on them ranging from raw blanks to assemblies in 60-80% completion.

After seeing the factory I wanted to see what else was inside and looked for a way into the factory. I located a side door and proceeded to look around and examine what was being manufactured. The operation was very basic and not at all advanced. The operation relied on standard machine tools such as lathes, milling machines and drill presses. The floor of the factory was littered with production jigs, gages and small parts. The factory had been looted and nothing of value remained inside. As I examined the factory I realized I had not seen a single magazine or magazine assembly. Maybe the magazines were manufactured offsite or another location in the complex. This was my sole visit to the factory as it was under guard afterwards and remains one of the best memories I have of my time in Iraq.

Overall I encountered a variety of weapons during my time in Iraq, everything from 1886/93 Lebel rifles to Colt Diamondback revolvers with German proofmarks. While I had a background as a small arms repairman/armorer, I always sought out weapons and militaria as a collector first and foremost. What some saw as a worn out old rifle or curiosity, I viewed them as unique historical artifacts with interesting stories. In some ways I went to war not as a United States Marine but as a hardcore Cruffler/collector and my experiences reflected my interest in historic arms.

Biography

Robert “Nick” Crawford

Military Experience

U.S. Marine Corps (1998-2004)

B Company 4th Assault Amphibian Battalion

MOS 2111 Small Arms Repairman/Armorer

Civilian Experience

Curio Relic FFL Holder 1994 to Present

Firearms collector for 22 years

Specializing in pre 1950 military weapons

Handloader

Education

Texas State University-San Marcos

Master of Arts History Program

Currently enrolled

Texas State University-San Marcos

B.A. Anthropology/History Double Major

Graduated 2014

Honor Graduate of U.S. Army Ordnance Center and School

Great story!

My own fascination with firearms really began when I was 14 and got a copy of “Firearms of the World” in 1969. The one page on South Vietnam shows copies of the M1911A1 and the Browning Hi-Power that were manufactured by the Cao Dai, with whatever tooling they could get, and I realized one didn’t have to be Colt or Fabrique National to make serviceable weapons!

The Cao Dai High Power copy was interesting, because it had a 1911-type slide, complete with separate barrel bushing and recoil-spring plug, while retaining the Browning cam ramp instead of the Colt swinging link. It also had a “slab-sided” slide like a Colt, instead of the “scallop” on either side near the muzzle typical of the FN pistol.

The Colt-type bushing is easily understood, as the cuts needed to make that work in the slide are easier to make with hand tools and drill presses, etc., than the ‘blind’ cutout of the FN slide. (The Spanish Llama and Star automatics used the same setup for the same reason.)

As for the slide treatment, the Argentine copies of the HP made in the last two decades do it that way, as well, to economize on production costs by reducing the number of machining operations. The Cao Dai no doubt did it to leave more metal around the barrel bushing locking recesses. Plus, they probably just didn’t think it was worth the extra time and aggravation just to make it look more like the “real thing”.

They were trying to win a war, not a beauty contest.

cheers

eon

First of all, sir, thank you for your service to our country and the cause of world peace.

Secondly, what you described is a very typical gun manufactory as you might have seen it in the Eibar region of Spain a century ago. The Eibar type automatic pistols and even S&W revolver copies were made in just this manner. Machine shops rather than true “production lines”, with a great deal of handwork usually paid on a piecework basis.

The gunmakers were artisans, not production line workers as we use the term. Even machine operators were trained not so much to just “run the machine” but in how to use it to make a specific part.

The machine tools in use would be for the most part the basic types you describe, as opposed to specialized gunmaking tools. In the case of the Eibar guns, this led to some peculiarities such as the curved slide grasping grooves seen on some of the blowback automatics. They were made with a cutter on a lathe head, because the factory didn’t have a milling machine to cut straight grooves.

The workers in those factories were trained by what amounted to an apprenticeship system, as opposed to a trade school. As such, you would find workers who knew how to file a hammer from stock but not much else, etc.

The Eibar plants often had small components such as springs, etc., made “off-site”, generally by small cottage-industry shops run by a single family. Some of these concerns operated for a few generations doing nothing but making springs, magazine followers, etc.

There might have been a similar setup in use at Tariq, which might explain why you found no provision for manufacturing the pistol magazines there.

Overall, the Tariq factory likely operated very much like those in Spain. As to whether this was based on expediency, someone actually studying the Eiber operations, or some form of cultural tradition affecting both Iraq and the Iberian peninsula, that’s another debate altogether.

cheers

eon

At the same time, looking at the quality of the Tariq pistols shows what can go wrong with such a process. Because it’s up to each artisan what is ‘right’ after they finish their apprenticeship, you easily run into problems where the artisan is simply not making the part to the right dimensions (their own mistake or one of the artisan they apprenticed under) and no one can correct them because no one else knows how it’s supposed to be made- even if it’s evident that the parts don’t fit together right, there might be no recourse besides reverse-engineering the part all over again. And because each worker cannot be replaced quickly or easily, there’s a lot of room for dropping to the lowest common denominator. If they’re paid piecemeal, then they want to get the most money for the least work, so what constitutes the least work that won’t cause them to be replaced is what you’re going to get 99% of the time.

In old factories the work benches were on the perimeter of the building to take advantage of any sunlight that would come in through the windows. That was where a workman spent his day with a vise at elbow height and a collection of cold chisels, files, lapping compound, etc.

Before electrification, machine tools were massed together as they ran off of a single steam engine (or a water wheel or a gas engine or maybe a simple DC motor) that drove sets of overhead shafts and belts. There were cases where belts even went underground if the power house was separate from the machine area. It was easier to line them up in parallel rows. For a long time thereafter, that was still how one laid out a factory, because that was how it was done. I worked a plant ten years ago that dated back to the 1960’s, and sure enough, the machine shop had all the lathes lined up in neat rows even though shafts and belts had been gone decades before that shop was built.

Regarding magazines, a simple mechanical C stamping press is cheap where OSHA is not around. But, maintaining the dies takes some expertise, and takes surface grinders, demagnitizers, and such to maintain and it takes a good machine shop when the tooling wears out. Also, a mechanical press can “wreck” and tear up tooling in the blink of an eye if some scrap is left in place, the strip jams up, etc. If the operator is not diligent in gaging parts coming off if it, a pile of scrap can be made in short order. If it was a small shop making guns, out sourcing magazines would be really attractive. The expertise to keep the dies in shape could better be spent in making jigs, fixtures, and gages for the machining operations.

When I was stationed in New London CT in the late 70s I spent a lot of off-duty time about 12 miles upriver in Norwich, which at the time was a sleepy little former factory town that had last boomed during the era of water power. (I’ve heard that since Foxwoods Casino opened it has become a bustling and much more expensive place to live.) Never knew where the Hopkins and Allen factory was – and it seems like several other “hardware store brand” guns were made there – but I did see the inside of several abandoned brick/ stone factories down by the river and they were obviously designed for sunlight to be the main light source.

About 15 years ago a neighbor – one of those guys who makes a living with a truck and a trailer – told me that he had cleaned out an oil-field equipment machine shop a few miles from downtown Houston that had been boarded up since the oil bust of the mid-80s and was scheduled to be demolished for residential redevelopment. The sheet-metal building was filled with postwar American-made lathes, mills, etc… he rented a forklift and hauled off the machines to the scrapyard for $3/ hundredweight and made some pretty good money, but the first thing that popped into my evil little mind when he told me the story was “STEN gun factory.” If not something more advanced, but just playing with the idea I realized that the most intricate/ demanding component would be magazines.

Probably any small arms manufacturing shop looked that way including such industrial country such as Canada. They had Long Branch Armoury going on since early 40s till June 1976 when they finally closed the door.

http://www.pbase.com/mrclark/long_branch_factory

Production started with .303 Lee-Enfield rifles and ended with Canadian version of 7.62mm Nato FN FALs. It was sequential operation in step by step, each for every special setup or fixture. Hardly any other way to do things before CNC age took off.

Ian, can you ask Robert Crawfordfor more photos?

Unfortunately, he doesn’t have any pictures of the factory itself.

An excellent, well-written article with an intimate personal viewpoint as expressed by a veteran who was there, and who was more aware of the context of firearms development and history than most — many thanks to Nick Crawford, and to Ian!

Jim In Houston’s information about the old lathes, milling machines and other manufacturing machinery being carted off for scrap at a lousy $3.00 per hundredweight almost made me weep. A lot of them were probably old Bridgeport machines or a near-equivalent, some of the very best and most reliable of their kind, operated by old-time machinists who really knew what they were doing — and where the exacting science and technical engineering of high-precision machining became a true art.

As an industrial-commercial diver and underwater engineer with welding, machining, NDT, pipefitting and other qualifications that have had to bridge the generational changes from the old-style technology to the current computer-driven technology, I can understand that times have changed and that we have to adapt and change with them. However, an intrinsic part of me still finds incidents like this a travesty in terms of the collective humanity and history that has been lost, not to mention direct, hands-on tactile man-machine interface skills that have been displaced by computerized machining ( such as CNC ). CNC machining is a marvelous tool that has enabled us to efficiently achieve incredible levels of precision in complex machining operations like never before, but I still have the greatest respect for the old-timers who could do things we today would seldom imagine possible using manually-operated machinery and outright skill.