Today’s article is another guest piece from Michael Heidler, author of several very useful books for the collector. This time, he is taking a look at the Italian TZ-45 submachine gun, and it’s unusual implementation of a magazine safety:

The TZ-45: Italy’s Late-War SMG with a Special Safety

by Michael Heidler

Italy and submachine guns – with these words usually three large names come to one’s mind: Villar Perosa, Beretta and from the 50’s-years Luigi Franchi. Until the end of World War Two only few other companies tried to break into the market dominated by Beretta. Only the model 1943 of the Fabbrica Nazionale Armi di Brescia and the TZ-45 of the Armaguerra Cremona went into serial production.

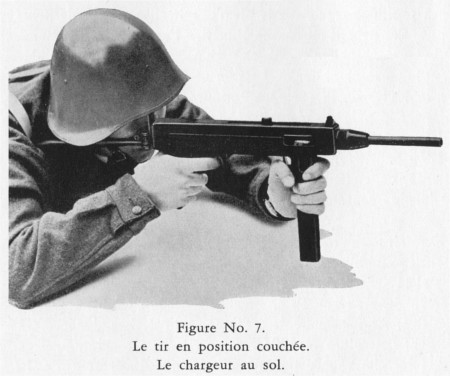

The L-shape grip safety is located behind the magazine well.

At a first glance the TZ-45 looks like a typical submachine gun of it’s day: A simple blowback system (open bolt), constructed of sheet metal parts fixed to a tubular receiver. Only the grip plates are made of wood. The retractable steel rod stock resembles the American M3 (Grease Gun). In the pushed-in condition the ends of their two rods are resting in a holder plate beneath the barrel. When shooting from vehicle hatches this plate also prevents an accidentally withdrawing of the weapon. That’s a similar safety precaution as the hook-style barrel rest of the German MP 38 and 40.

But the TZ-45 has some more special: An automatic grip safety. Such a thing has never been used on a submachine gun until then. At that time, apart from saving raw materials, the needs of a simple and speedily manufacturing process had priority before all. Little attention was given to safety. Not so with the brothers Tonon (“Toni“) and Zorzoli Giandoso, when they were working on the draft of their first submachine gun. They created a very simple but effective safety which became active by itself. All other submachine guns only possessed manual safety devices.

The automatic grip safety wasn’t a mold-breaking innovation. Already some early self-loading pistols like the German Pistole 08 or the Colt M1911 featured a grip safety on the back side of the grip, which was only released by a firm clasp of the shooter’s hand. In German it’s called “Handballensicherung” (heel-of-hand-safety). But for a submachine gun this construction was too complex. Therefore the brothers Giandoso transferred the safety to the outside of the receiver behind the magazine well. It only consists of a spring-suspended L-shaped lever, which projects into the receiver and blocks the way of the bolt. Only if the second hand clasps the magazine well firmly, and presses the lever forward, it releases the bolt. As soon as the shooter’s hand loosens, the lever snaps back again and the weapon is safe. No matter whether the bolt is in its front or rear position.

Despite all adversities and the foreseeable end of the war the Giandoso brothers succeeded in manufacturing nearly 6000 weapons in their own company “Armaguerra Cremona“. A majority went to the units of the R.S.I. (Repubblica Sociale Italiana) in Northern Italy to fight against partisans. The magazines of the TZ-45 are identical to the Beretta submachine gun magazines, so in mixed armed units they could be easily swapped during combat.

After the war some weapons were brought to England and the USA for trial measures, but were soon classified as outdated. However the Burmese government bought the rights on the construction and introduced the weapon as “BA-52” in their army. For support during the preparation of the serial production Tonon and Zorzoli Giandoso went to Burma. Afterwards their trail was lost. Production numbers and the period of official use in the Burmese army are unknown.

The safety of the TZ-45 was foolproof – nevertheless it did not continue to become generally accepted. After the war more quality and comfort were required again. Numerous submachine guns received an integrated grip safety like the pioneer ZK 476 from Czechoslovakia, the UZI from Israel or the Beretta models from 1955 on. Thus also a crucial disadvantage of the TZ-45 was eliminated: both hands had to grasp the weapon when shooting. One-handed shooting, e.g. after being wounded, was not possible. Same with different aiming styles during an attack. That could be a crucial disadvantage in fighting. Furthermore the safety had not been optimally designed: The shooter had to press the shorter arm of the L-shaped lever, which required a strong grip due to the leverage and the strong spring. If the hand fatigued, the lever began to touch and slow down the bolt moving inside the receiver. This often led to malfunctions.

A new attempt: The problem was recognized, namely by the Danes. The company Dansk Industri Syndicat A/S (DISA) from Copenhagen was one of the few, that built a submachine gun with grip safety at the magazine well again. In the year 1946 their “P.16“ went into production, better known as the “Madsen 1946“. The unusual construction with the laterally hinged receiver featured a more favorably placed lever. The bolt is caught by the lever’s nose just before it’s end position. To hold the bolt in the rear position a manual sliding-safety was used. The grip safety seemed to have worked satisfactorily in this case, because it remained unchanged with all revised subsequent models (M.1950, M.53 and Mark II). Beside the Danish police the weapons found their way mainly to South America and Asia. Larger quantities were sold to El Salvador, Paraguay, Guatemala, Colombia, Thailand, Korea and Indonesia.

Despite the success of the Madsen MPs the history of the grip safety at the magazine well already ends with these two weapon models. No more other weapons manufactured in series possessed this safety.

Technical Specs (TZ-45)

Caliber: 9x19mm

Length, overall: 33.5 in (851mm)

Length, stock collapsed: 21.5 in (546mm)

Barrel length: 9 in (229mm)

Weight, unloaded: 7.0 lb (3.2kg)

Magazine capacity: 20, 30, or 40 (uses Beretta M38 magazines)

Rate of fire: 600 rounds/min

The author wishes to thank Al Houde of the U.S. Marine Corps Museum at Quantico, VA for his assistance.

Another excellent and informative article! Vielen Dank! Thanks!

The Duce of the R.S.I., Benito Mussolini, was executed by Italian Garibaldini/partisans with a “forgotten weapon” smg, namely, the French MAS-38: http://armesfrancaises.free.fr/PM%20Mle%2038.html

There is a 1997 Brazilian film _O que é isso, companheiro?/ Four Days in September_ by director Bruno Barreto about the 1969 kidnapping of U.S. Ambassador Charles Elbrick [played by Alan Arkin] by the terrorist/urban guerrilla MR-8–movimento revolucionario oito de outubro–that has an Italian submachine gun appear in it… I’ll have to see if it is the simplified 1942 beretta or the TZ-45! Basically, there is a scene where another urban guerrilla/terrorist group sends “reinforcements” to the kidnappers, and they have several SMGs in a suitcase… Now I know to look for that magazine well grip safety to determine which kind is portrayed in the film!

Anyhow, great stuff. Interesting site.

There were many groups and individuals who would have liked to have claimed bagging the brace of Benny and his mistress

One of the favorites with the locals on that part of lake Como, blames/credits one of Churchill’s agents for ensuring that Churchill’s offers of deals would never be publicized.

Franco Bartolini, discusses some of the local stories in his book “Secret Lake Como”, he also covers some of the wartime bunkers and defensive positions.

http://books.google.co.uk/books?id=jUbEGAAACAAJ&dq=secret+lake+como&hl=en&sa=X&ei=CM5MUd68MYeRO5OtgaAM&ved=0CDoQ6AEwAA

Google Images has a fair number of other good pictures of this interesting SMG.

What an interesting weapon. Thank you.

This appears like attempt to do something quick, kind of makeshift. At the same time the creators recognized necessity of some sort of added safety. This measure elevated genI SMGs to genII level. I recall story told by late U.Gal on accident which happend to his friend. He (the friend) jumped into jeep and his Stengun inadvertantly went off. The poor man was literally decapitated. This experience was starting point, in his mind when conceiving the famous UZI.

I’ve always like pistol grip safeties, like the Uzi and the 1911 series. The second-hand safety grip has always puzzled me though, as it becomes another reason for a gun to fail-to-fire. An improper or weak grip at the wrong time would be a very serious problem to have, especially in a life or death position. Had I been issued one of these two guns, I would’ve taped the grip safety in place.

Given that this idea died, along with trigger safeties on MGs (Maxim style, etc), it would appear that others agreed with me.

A very interesting looking gun. Thanks for sharing.

The receiver is more than just a “simple tube”.

It looks like it has been turned down from the wall thickness shown by the ring that the rear sight is fitted to, and the rear end.

The rear appears to have been turned using a form tool to get that radius, the sight band appears to have had a different tool forming its front edge.

The chatter marks over the length of the mag and ejection ports and cocking handle slot, perhaps indicate that these openings were formed when the receiver blank was still at its full wall thickness – before it was turned down.

all of that slow and expensive turning, when the mag housing clearly shows it is attached by welding, why weren’t the full diameter bits of the receiver just welded on as well?

Some rather scabby vertical milling is evident on the rear sight mounting ring, to clear the way for the firer to use the cocking handle, and the stock mount also appears to have been milled!

The stock brings out one of the more intriguing questions – the marks on the sliding rods, are characteristic of them being turned to diameter on a turret lathe or an automatic lathe – so either the stock was not designed to use an available pre drawn rod – or, such material was no longer available when this particular gun was made.

all of that metal being turned into chips, and the nice pressing to form the housings for the trigger mechanism and the mag, contrast sharply with the peened on selector lever and the two piece slotted barrel jacket

it’s an interesting bundle of contradictions.

I can see you are man of trade Keith. Yes, you are right, contradictions, but what to expect during war time? I am surprised that raw material (tubing, sheet metal, bar stock… or welding electrodes) were even available. And they were bombed day and night on top of it. I recall all kinds of talk from past experience with ME people asking to change this or that for whatever the reason may be. This was in peace time, of course.

As Keith has pointed out, the manufacturing process, based on the visual evidence provided by the individual components of this gun, appears to be a bundle of contradictions. Perhaps the main reason underlying this mixed bag of manufacturing techniques is that by the time the TZ-45 was approved for production, the general situation in Italy had deteriorated to the point where they were forced to use whatever manufacturing tooling and technology was immediately at hand, hence the seemingly odd hodge-podge of milled, stamped and peened parts. The exigencies of the late war period may have also effectively prevented re-tooling to a lower-grade but nevertheless standardized manufacturing level ( eg, all-stamped metal construction ), thus contributing to this issue.

They had to improvise from day to day, most likely. Just brings back flashes of like the reality might have been from movie Catch22. For guys above (allied bombers) is was daily business routine, no questions-no complains, just do the job. I can hardly imagine how people were able to sustain that and to make product like this.

With the recent major political changes in Burma and the resulting opening of the country to the outside world, it might not be amiss to see if any of the Burmese-manufactured TZ-45’s / BA-52’s is currently available to private collectors and museums.

It would also be most interesting to find out the eventual fates of Tonon and Zorzoli Giandoso after their disappearance from the public record ( presumably in Burma ), because this would fill a vital socio-historical niche in the somewhat checquered career of the TZ-45. After all, the story of the gun is never complete without the story of the man ( or woman ) behind the gun.

Talking about technological hodge-podge and daily improvisation, here’s some photos of another TZ-45 with aluminum magazine well, just like the middle guy in a vintage photos set carries. I’ve sent the pics to Ian for processing (I don’t even know if there’s a possibility to include pics with the posts, but not seeing any, I gather it is not possible) so cahnce is, you’ll be soon able to see it not only up-close, but stripped as well, for all fellow gun-porn lovers out there 🙂

Actually, there was another smg with that safety. During the 50´s, FMAP from Argentina made a US M3A1 copy with that safety, the “PAM 2” in 9×19 mm, still in use for parades.

http://imageshack.us/a/img696/8707/museo8.jpg

Thanks, Markost! You jogged my memory with the photo and description of the FMAP PAM-2. I remember reading about it thirty or so years ago in an article on the state of the small-arms inventory of the Argentinian Armed Forces in one of the international defence publications ( it might have been International Defence Review, but I can’t say for sure ).

The problem with bombing accuracy during WWII – it was virtually impossible to hit a small shop making 20 or 50 smg a day, if the allies even know about it. Hence the idea of terror bombing, try to take out the civilian workers and infrastructure to make production grind to a hold. Wasn’t much more effective, as it just lead to a more dispersed production, with hardened facilities for critical plants.

From today’s “headlines,” possible interest:

http://news.yahoo.com/blogs/sideshow/mussolini-most-secret-bunker-discovered-beneath-historic-roman-015542530.html