Sold for $1,610 in the February 2020 Sport & Collectors auction.

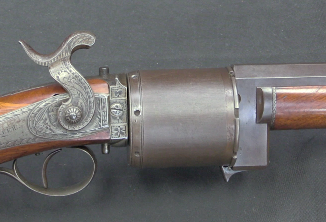

Ross Rudd was born in Toronto in 1915, but his family moved to Springfield Massachusetts in 1917, and he would grow up there. Interested in guns and gun design from an early age, Rudd went to work for Savage in 1940, where he was involved in Lee Enfield production and the simplification of the Thompson SMG. In the early 1970s, he formed his own company to produce a pistol he designed using a clever delayed blowback design. He also adapted the system to a rifle, and it is his prototype AR-180-based rifle that we are looking at today.

While the mechanical system seems sound, and his prototype pistol appears to have run well, Rudd was unable to find a financial backer for the project, and neither the rifle nor pistol ever went into production.

You can see Rudd himself explaining his pistol here: https://youtu.be/7lAxVYYhACM

And his patent here: https://patents.google.com/patent/US3998126A/

This is indeed example of forward thinking. If there is a negative, it could be accelerated wear at contact/ locking surfaces. That can be overcome by exchanging parts with selected hardness (likely the shoulder in receiver) – for minor cost.

Someone in discussion at YT suggested its application in pistol. Hmmm, food for thought. Overall, rather refreshing. Thanks Ian and keep up with your work!

“(…)application in pistol(…)”

Ross Rudd developed .45 caliber delayed blow-back automatic pistol code-named SINGULAR, see 1st photo from top here: http://www.mythicarmory.com/ross-rudds-45-prototype.html

“(…)food for thought(…)”

Before undertaking any action related to that please read Delayed bolt action for firearm (US Patent 3998126) by Ross Rudd

https://patents.google.com/patent/US3998126A

to avoid wheel reinventing

Excellent finding!

He shows slide upside down with moving “Bolt” inside of slide, but does not show where it engages Frame. The patent address rifle, not pistol. I do not feel need to latch on this, but appreciate he information.

Has anyone seen the Radial Delayed Blowback operation?, its used on the CMMG MK57 but would it work with 5.56x45mm NATO?. If so it looks more hardwearing than Roller Locking/Lever Delay operations.

https://www.youtube.com/watch?v=vXPqxC6Z4kI

Never heard what caliber he planned for it!! Great Ideal but could it handle the bigger cals (308 an up)

I doubt it would. The reason is Off centre load and reaction to it, which will likely go into guideways/ rails. For .223 it may work, with some noticeable wear. With HK designs you have equilibrium of load/ resistance to it centred around bore axis and wear is manageable.

Gas strut. Sorry, going off on “tip up” springs again.

Cheap… Ok the bolt looks fairly well machined, meh big spring Zamak $200 bux.

Of course you have to factor into it the shoulder lock angle. You may want to look at patent Daweo came up with. Get yourself sheet of paper and start sketching; it will become instantly clear.

Thanks to Daweo for that “missed it, being all enthused in lockdown” I’ll look at that again… Still thinking zamak mind currently he he.

Remington R51. Pistol… Mind you I have been drinking. Still have that on the brain, mental trauma really; he he.

“Not to make light of a serious issue, including Lariam”

Love old gun mags, great weren’t they… I’ll have to look at that patent etc another day; beer, burp. But cheers.

A rather witty synthesis of ZB29, G3, Thompson and BAR.

The design is interesting but useless.

I do not see noticeable advantages. But it turned out a concentrate from the shortcomings of these systems.

“(…)ZB29(…)”

What is that?

Apparently he meant tilting Breech lock on ZB 24/26. But that is off the scope of this topic since it has gas piston control built into it.

If it were not a working sample, it would be were hard to beleive its functioning…Leverage seems having mechanical advantage… Instead of disadvantage… Inclined contact surfaces seem little delay providing… The bigger mass of slide and receiver of rifle seeming sole factor getting disadvantaged accerelation… Hats off Mr. Rudd… IMHO…

>Leverage seems having mechanical advantage… Instead of disadvantage…

I believe you’re referring to the cam pin being closer to the front pivot pin, while the “locking” surface is farther?

Let’s throw some numbers at it, assuming a leverage ratio of 1.25 or 0.8 (depending which way you look at it), and further assuming that both camming angles (in the upper receiver and in the bolt carrier) are 45 degrees.

For the bolt to move rearward 1mm, the tail of the bolt must drop 1mm.

When the tail drops 1mm, the cam pin drops 0.8mm.

So the bolt carrier is pushed back 1mm (along with the bolt) plus an additional 0.8mm (from the cam pin moving down its track), for a total of 1.8mm.

Thus, the bolt carrier’s mass sees a mechanical advantage (or equivalently, the bolt thrust sees a mechanical disadvantage) of 1.8 — certainly less than the ~3:1 ratios we usually see in delayed-blowback rifles, but the ratio is still in the usual direction.

Thanks for interest… l would like to point out the distance from rear pin to the top of cam lug…Leverage seems occuring over that pin…

So no? He he.

Would that bolt carrier be equal to the mass acting on the angled surface things, engaging the rollers?

In a Hk.

Think about it: it order to “unlock” he’s got to act with those pins hard enough at slant/ angled slots in carrier. Anything more than static friction angle (5-7deg for steel) will go. He’s got it at what looks like 45deg.

I reckon my meccano diamond trellis with a further “half trellis” ^ with a gas piston pinned on its front, to get gas from a barrel port, thus preventing the trellis contracting inwards would work.

Meh it has rollers, all good. (Meccano: Jager pistol ww1)

“THEY AIN’T GETTIN THE T.V” Mars attacks.

It’s fundamentally sound; you just need to think of the bolt etc, being… Not conventional. Jager, but inside.

No reason why it should not be. Bayonet mount: Defeat the Zombie Hun in 1946.

Wooo!

Should have been a “Ghost” emoji then… Woooo! See.

Bolts thus; Can be laminates, stuff.

Good stuff… Shit robots will be firing at you in future.

Possibly; so its good, Google amassed knowledge.

It’s possible to make even the most idiotic design work. If only there were no springs inside the barrel. 😉

Slowing the unlocking in the system is achieved not so much due to the fictitious mass (as in normal linkage systems), but due to friction.

And friction is everywhere …

Considering that when firing the bolt and the carrier bursts with great force in the upper, it will have to be made strong and heavy, otherwise it will simply inflate. Well, most of the other elements are designed technologically illiterate.

I have no doubt that this can work with a certain geometry of parts. But this is just the case when the system does not work “thanks” but “contrary to” the applied solutions.

Stillborn.

Blish lock? What springs inside the barrel? Do you mean “heat” from the barrel, makes springs less (springy) boing!

“What springs inside the barrel?”(C)

It was apagogy. 🙂

It’s just that this is the only thing that occurred to me as an even more ridiculous solution than the one applied.

In general, in mechanics, there are many different mechanisms that automatically turn on only when the control part reaches a certain angular velocity or linear acceleration. But in smallarms they are usually not used.

At the beginning of the last century, there were several samples of self-loading weapons, in which the return spring is disconnected when manually cocked.

There were rifles, and machine guns, and autocannons.

Some of them are described by Ian.

https://www.youtube.com/watch?v=gtCLiY9I6dQ

Apagogy; New word, to me cheers. I see what you mean, well… Thats why Ians arc… hive, is important; I forget. Alot. Of like info, which “enthused” me, at the time… Be handy for future generations. Vs Terminators or not. On hand, like a diary. Moo. Dairy; Bse, British thing.

https://en.wikipedia.org/wiki/Reductio_ad_absurdum

Pardon if disappointed.

But it’s not so serious.

No? 😉

I’ve seen a Badger. I totally get you; tut, life!

“Blish lock?(…)”

This is supposed to use stiction

https://en.wikipedia.org/wiki/Stiction

this does exist, however if it has any non-negligible effects in case of low-pressure .45 Auto cartridge is another matter.

Well that was interesting… Whats that pistol with the spring above the barrel… “Ye olde” FN 1900 might be that, might not be; but it would be something very similar… Anyway I remember discussing, that you could perhaps… Well, it was to do with a “tip up” spring I.e. A strong spring, that you could use in firing but not in cocking; because you moved it.

Anyway if this opens too fast, really; given the lack of mass acting on the rollers unlike in Hk’s, as is my understanding. Then with this, a stronger spring might be the cure; and that could be via the “tip up” well… Disengaging spring; in order that to cock it, it disengages (as it would be “springy” tough, like) but in firing; more springy.

I like it; it’s simple, I just wonder given it’s simplicty; why it never took off.

It’s pressure isn’t it acting on the bolt “no inertia” or such… So, it seems very simple… It’s good, in away. But, does it work well; given how simple it is… I mean thats an improved Ar180 if it does, I’d have thought. Which makes me think it doesn’t.

Pistol: Frommer Stop… Forgot. I remember folk saying “springs” aren’t generally used, for delay… But if this lacks delay, I reckon thats the more simplistic solution in this case. How, er… Spring running over the barrel; disconnect thingi ma bob.

Hi point .556 no? Angled piece with hook on end of forward pivoting spring, cocking handle engages said angle up.

You fire first? Mind you the out of battery safety is probably enough to prevent serious injury; outside of court.

Hmmm… Maybe it would be a decent “simple” idea, in war.

“(…)Hi point .556(…)”

What is that? Do you have any photo of such weapon?

No… But a spring might help this delay better, or failing that a weight over the barrel; that is lifted up as the front of bolt goes up as its rear goes down in the carrier. Hk rollers are acted on by a mass, its not simply the angle of surfaces.

“(…)strong spring, that you could use in firing but not in cocking(…)”

Dreyse automatic pistol for 9×19 mm cartridge

https://unblinkingeye.com/Guns/D9mm/d9mm.html

?

Aye that sort of thing, talked about it on here for sure. Thanks for that link; I’ll read it again.

The vertical offset between the center of the breechface and the front pin on the bolt are important to how this gun works. As the cartridge is fired, the bolt pitches upward at the rear into tighter lock up. IMHO

“Thanks for interest… l would like to point out the distance from rear pin to the top of cam lug… Leverage seems occuring over that pin…” Thats a quote from above… Do you mean, something similar to that? Well if it works, sure.

“Not that I understood”

Sure… Yet, it still didn’t really work maybe? It just was too, quick.

My view is that its flapper locked, sort of, with only one flapper. The bolt is the flapper. To unlock the gun either the pressure on the bolt face is reduced enough to function as Strongarm describes, or the inter play between the bolt carrier and the front pin changes and reduces the upward force on the rear of the bolt. In the video with Rudd and his pistol, it works upside down. What is he trying to show?

Flapper delayed with only one flapper, it’s a Remington R51 in 5.56 upside down; if it works well I’ll be very surprised. In the video of Rudd with his pistol “which I have seen before; when looking into the R51” he is showing that you can shoot it upside down I.e. That the bolt is still in battery, as the pistol is upside down; or the right way up, bit like Australia. You could doubtless shoot this upside down, but I still doubt it works well.

Well ok, no it isn’t a Pederson hesitation “lock” I haven’t “traumatised” myself about that for some time; so I forgot, but it’s similar apart from in that pistol the slide moves a bit first. Which to me is probably a better idea, in terms of delay. Although in his video the pistol seems to work. Well anyway, I find it hard to believe it is really that good given it never took off, the pistol. But this rifle, it just strikes me there is probably not enough delay; it isn’t a Famas type thing, nor a HK, nor gas, it just seems to simple.

Too simple for 5.56mm, that bolt carrier is tiny “in that short ar180 action” can’t weigh much, is he not just “Riesing” it basically, but in 5.56.

Call me an idiot, but perhaps the reason this rifle didn’t sell was that there were plenty of good weapons on the market. “Why bother with a novelty when a proven system already exists for a lower price tag?”

No. Theres something up with it, unfortunately I think; it would be way cheaper to make, if it worked.

Must open too quick. Not having that failed; otherwise the ar180 would have succedeed, half price that mod easy.

Might be an idoit etc, me, moo. But like… I mean… Its so simple.

For the time; excellent, no Forgotten weapons etc. So a super theory, but must have failed in practice.

“(…)if it worked.”

Would that rifle work reliably with wide variety of loading?

He’s removed the entire gas system; surely thats cheaper.

Cheap Government… Bar moon landing fuck off huge ex Nazi designed rockets type thing.

“(…)Bar moon landing fuck off huge ex Nazi designed rockets type thing(…)”

Could you explain this?

Those wee Ak74’s thats a quality gun, fair play to Osama for that; those 5.56mm Hk’s are awful.

In the same sort of category, an EM2 is what you want really in general use with a bayonet.

They just do not like it up them.

Infected Coronavirus natives; move along. Push, prod. Follow your Government text go home. He he.

That locking system reminds me of the one Savage uses in their A17/A22 magnum. Even locks into the receiver at a similar location

https://www.youtube.com/watch?v=xH4wk6pOTrU

The Savage A17/22 really is remarkably similar, though it uses a vertically moving wedge.

Makes me wonder why no one has picked up the Rudd Patent, as Rudd’s design seems simpler to me and should work best with lower pressure cartridges like rimfires or pistol calibers. When does the patent run out?

“…should work best with lower pressure cartridges…”(C)

Perhaps because there is no need for “lower pressure cartridges”.

Any delayed-blowback system makes sense only if you have to use a bolt of too much mass with a simple blowback. For example, for a cartridge of 7.62×39, the mass of a simple blowback bolt should be no less than 2.6 pounds, and preferably about 3 pounds. And everything works.

The use of delayed-blowback allows you to reduce the mass of the bolt, for the price of a more complex and expensive design, as well as worse reliability and (in some cases) worse accuracy.

In addition, the use of delayed-blowback allows you to change the speed curve. With a simple blowback, the speed of the bolt reaches its maximum almost immediately, after which it decreases almost linearly. And with delayed-blowback, due to the redistribution of the recoil momentum, the bolt starts at a lower speed, and after attaching the carrier to it, the speed of the bolt jumps to the maximum and further, as with a simple blowback. This kind of speed curve is more convenient to prevent tearing of the case with a minimum mass of moving parts.

Also, most delay-blowback systems are quite sensitive to friction, the strength of which depends on the presence or absence of grease or dust. And the more friction points, the stronger this dependence.

An ideal system could be in which the capacity depends on the power of the cartridge, and this does not depend on friction .

But I don’t know that…

I’d love to get an engineering explanation from Ian or someone knowledgeable about manufacturing on why gas-operated rotary locking bolts became so dominant (particularly combined with a piston system).

There seem to be a lot of tilting bolt and some lever-locking systems up through the 50’s and the odd delayed blowback (HKs and FAMAS) rifle, but few after.

Just spitballing, but rotary bolts offer very symmetrical lockup close to the bolt-face, and locking into a barrel extension means that the rest of the receiver can be made lighter while gas systems allow reliable functioning with a wider variety of ammunition.

is this the way the Riesing SMG works ?

Rudd cites the Reising SMG in his patent. But I think he improved on it by having the bolt also push the bolt carrier back at a mechanical disadvantage. Is there any mechanical disadvantage between the Reising bolt and it’s op rod?

“…Is there any mechanical disadvantage between the Reising bolt and it’s op rod?..”(C)

Perhaps one disadvantage.

Unlike Raising, which, although not very reliable, but works, this design (as presented) is dead.

Both designs are a development of Blish’s design.

But Reising had the opportunity to exercise.

Perhaps, for a respected author, they organized an excursion to the factory in order to hint at the need to continue training…

Great Article. I was checking continuously this blog and I’m impressed! Extremely helpful info particularly. I hope more from you. I was looking for this certain information

The patent application expired today.

2020-04-08 Application status is Expired – Lifetime

The validity of a patent application, if an extension is not filed, expires after 14 years from the date of registration.

Blish’s patent expired in 1932, Payne’s patent in 1938(39?), Reising’s patent in 1983, and Ross Rudd’s patent in 1993.

De facto, we can say that the Ross Rudd’s patent infringes the Reising’s patent…

But this is of no interest to anyone, because it is useless.