This rifle sold for $3,450 at Rock Island on December 1, 2018.

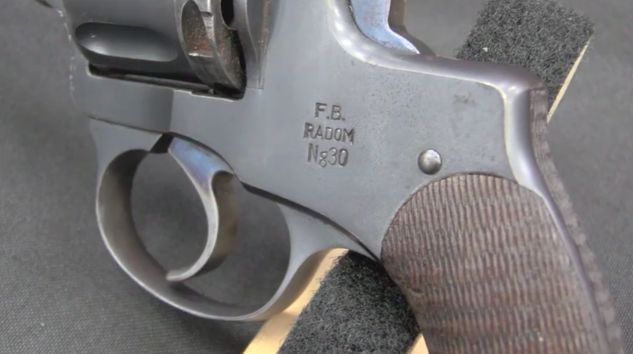

How did people determine chamber pressure in the years before computers and fancy electronics? Well, by squishing a calibrated slug of copper. Factories would convert rifles specifically for pressure testing use by adding a pressure ring around the chamber, drilling a hole in it, and then threading in a gage to crush a block of copper. This Mosin Nagant is an excellent example of the system, complete with the all the testing apparatus!

Well, that explains a question I have had for a long time… What is a CUP (copper units of pressure) measurement, and how is it derived.

Just curious, does the slight offset allow use of the sights?

In industry, both systems – CUP units measured by copper crusher and PSI(MPa) pressure reading obtained by piezo-sensors (e.g. Kistler https://www.kistler.com/en/products/components/pressure-sensors/)

are used. Major difference is that with CUP you get maximum measurement only and with sensor you get profile of pressure buildup.

Nominally CPU units are slightly smaller than PSIs; there is even formula to convert between them which looks little wanky. Here is page describing more exact method; there is also conversion chart for various calibers

https://www.shootingsoftware.com/ftp/psicuparticle2.pdf

However, there is nothing inadequate about older system.

Piezo sensor measurements are not all equal, either, but depend on the actual test setup. Specifically, the methods used by C.I.P. and SAAMI produce slightly different results. And I don’t mean that the former are in SI/metric (unit is MPa or bar; bar is exactly 0.1 MPa or 100 kPa) and the latter in Imperial (PSI), either.

I suppose either system has its own standardized, or recommended way how to do the setup. What I have seen was based of company’s experience, which was most likely based on recommendation of sensor’s manufacturer.

Yes, I remember BAR (in NA it usually means lawyers association :-)), I grew up on it – kg/cm sq. It was easy to work with, just as with all metric system.

If the testing apparatus is still functional, maybe set up a special one-time Patreon deal so you can put a bid in for it (assuming you don’t plan to anyway) so we can get a video of it being used. I’d chip in a few $ towards that.

Good idea, if you were assessing pressure in case of experimentation with re-loading. But keep on mind that you have to drill a hole into barrel, effectively destroying it. Sure, you can plug it back, but it is not same like original.

I wonder, it there is means how to do it without mentioned hole, for example by strain gage attached to outer periphery (as a comparative measurement). Since I am out of industry for number of years I do not know much about new technology; there s some new and amazing stuff showing all the time.

There’s always better non-destructive methods, but some things can’t be done that way. In some factories, some part series have to be destructively sampled per month to ensure that the overall batch is good (customer requirement). I am part of this process with microscope work.

May I ask: metallography?

Yup! That’s my role.

Sounds like exciting job, but every one has its pros and cons. Too much specialization hurts, if you(g-d forbid) get laid-off. I happened to me too.

Ok wonks. Does the size of the hole drilled into the chamber

matter? Or is the pressure constant for any diameter?

Is there a somewhat simple answer in comparing CPU to PSI?

What other methods were used to determine chamber pressure?

I understand that the copper gets “squished “. But how does that translate? If you have the patience thanks in advance.

I’ll answer the first question: Yes, the size of the hole does matter. Say you have a bunch of 1 inch cubes that weigh one pound each. They exert 1 psi each. You put one on a marshmallow & it compresses it halfway. Then you arrange 4 of them in a square box and it smashes the marshmallow flat. On a flat surface it’s still only 1 psi, but on top of the marshmallow, it’s now 4 psi.

Same thing with the piston in this device – a larger surface area will transmit more force to the copper slug. You could get an accurate comparison of pressure no matter the size of the port, but the size would have to be consistent for all cartridges you test and it would have to conform to a known standard if you expect to accurately read pressure (if your port was smaller than standard your result would show less pressure than there actually was & vice-versa). The copper slugs all have to be standard as well. Any variance in metallurgy, temper or manufacturing process will affect the outcome.

And your last one, too. The copper is compressed by the pressure of the cartridge. Your slug is of a known length before firing & measured after. There’s a formula that turns how much compression equals so many CUP. A low pressure .45ACP at say 20,000 psi may only compress the slug a little, where a .300 WinMag’s 65,000 psi will squish it good. They measured how many CUP it took to kaboom a specific firearm/cartridge & kept loads within a safe range. Same as psi, but using a different methodology & units of measurement.

I tried external strain gauges without being able to obtain results that were reproducible. The barrel obviously experiences strains due to vibration that overlay those due to gas pressure. These seem to be reflected at the muzzle and travel backwards along the barrel, distorting the signal yielded by the strain gauges. Three loads (high, medium, low pressure) measured in a test barrel did not result in the same order of pressures based on strain gauge data.

Recreational Software Inc offers PressureTrace solution using strain gages(https://www.shootingsoftware.com/pressure.htm)

Excellent input gentlemen, keep it coming!

From my experience, while furnishing design of tooling such as collars into which the transducer would be affixed I recollect, they had very small port holes – about 1.0-1.5mm (0.040-0.060″) in diameter. The collar has to be attached to sample barrel thru shrink fit.

The output from transduced in form of millivoltage was amplified and used in computer program to produce desired data. It worked repeatedly and reliably.

Commonly the cartridge case is drilled so that the hole lines up with the crusher piston. This way you don’t have to know what offset the case wall will produce. In RF the case wall would just blank out into the hole in the chamber, the blanked disc then having to be pushed back into the fired case before extraction.