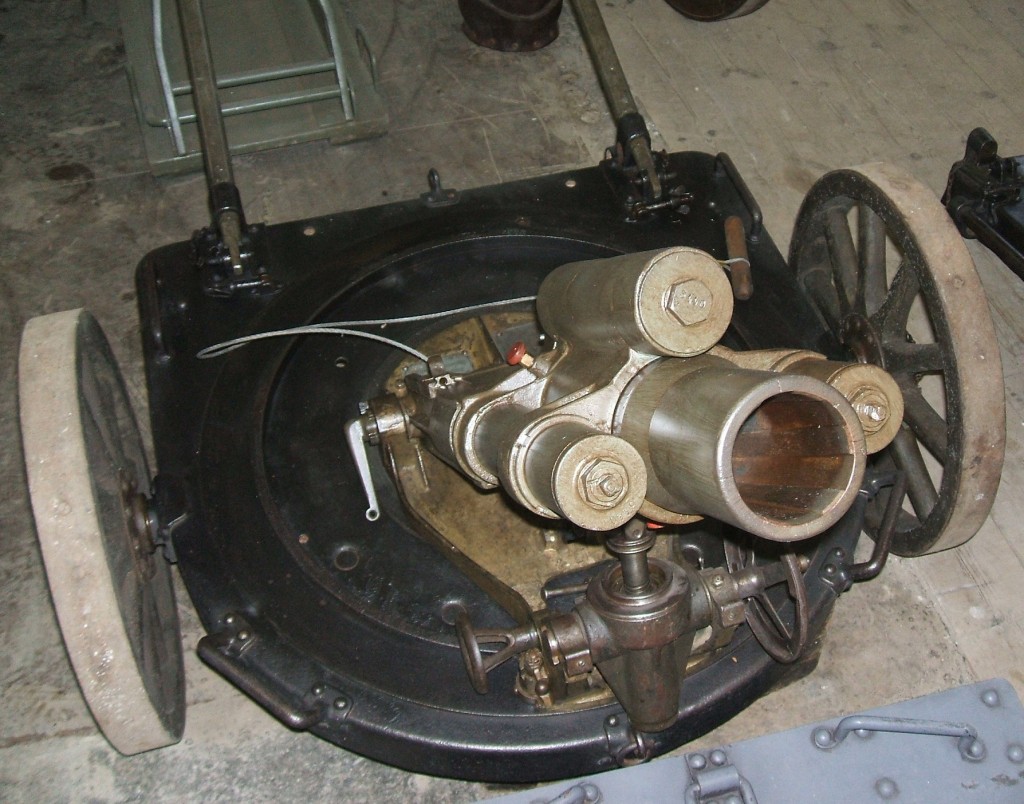

I’m on the road today, and don’t have a proper post ready – sorry! I’ve been hanging out with some folks into artillery, so I will distract you from the lack of content with a couple photos of a WWI German minenwerfer. This is a 7.58 cm Minenwerfer n.A. (new model), of which more than 12,000 had been made by the end of WWI. The first model was developed prior to WWI, and used a mount with a limits (7 degree) traverse and a short (9″) barrel – the new model pictured here (introduced in 1916) had an increased barrel length (16″) and a rotating mount that could swivel a full 360 degrees for much greater flexibility.

These light mortars would throw a 4.5kg (~10 lb) shell up to 1300m, and despite being one of the lightest types of artillery in the German arsenal proved to be very effective and useful. It was loaded from the muzzle like a typical mortar, but did have a rifled barrel and a hydraulic recoil dampening system (the cylinders for this are prominent on both sides of the barrel).

DEATH FROM ABOVE! Mortar shells can’t be predicted too well (nor can any indirectly firing artillery), so your best bet is not to stay still in the open. Use cover if you can, but don’t let a mortar unit spot you! If possible, get a sniper to nail the enemy mortar crew…

Anyways, this rifled mortar seems to emphasize accuracy over speed (line up the projectile so it fits the rifling grooves), considering it is fired by lanyard-tripping rather than by stationary firing pin (and therefore the projectile dropping on said pin). The Germans tended to have mortar pits dug when possible later in World War II to maximize protection for the crew (or so I think, please correct me if I’m wrong).

No, you’re correct, in both wars. The Wehrmacht believed that indirect fire weapons needed to be protected from direct fire as much as possible, much the same way our forces sandbagged arty positions.

BTW, this was the light Minenwefer. The “heavy” version was a 25cm;

http://en.wikipedia.org/wiki/25_cm_schwerer_Minenwerfer

And in-between there were the 9.15 cm “System Lanz”;

http://en.wikipedia.org/wiki/9.15_cm_leichtes_Minenwerfer_System_Lanz

And the 9cm M17;

http://en.wikipedia.org/wiki/9_cm_Minenwerfer_M_17

The two medium models were more like what we think of today when the term “trench mortar” comes up. Lightweight weapons firing light “bombs” to relatively short range.

It’s worth noting that by WW2, the Wehrmacht had dropped all of the above and was using a range of mortars based on the British Stokes design, just like pretty much everyone else. The Minenwerfers really weren’t suited to a war of movement, especially not a blitzkrieg.

cheers

eon

The Stokes-Brandt type smooth bore mortar is also much cheaper and has a much faster rate of fire. Accuracy with a well designed projectile is actually quite good after the base plate is firmly seated.

The rifled Minenwerfer was really an evolutionary dead-end, although the German WW2 75mm and 150mm infantry guns were quite often used for indirect fire similarly as the WW1 Minenwerfers, unlike for example Soviet 76.2mm regimental guns, which were used almost exclusively in direct fire mode.

You are quite correct in your assertions, even in the context of many present-day typical small-unit engagements involving indirect mortar fire where the protagonists involved do not have immediate access to counter-battery radar and other countermeasures.

It should be borne in mind that in situations where counter-battery radar tracking is available, it is relatively easy to track low-velocity fire from sources such as mortars to their points of origin and initiate effective counter-battery fire. Of course, what I am saying is in the context of the modern-day battlefield, and certainly not in the context of World War One when such means did not exist. However, bear in mind that even in the days before artillery radar tracking, it was generally recognized that frequent and rapid displacement to new firing positions was advisable, because of exposure to enemy observers who could then relay their findings to their colleagues, who in turn could work out retrograde trajectories and initiate remarkably accurate counter-battery fire. In today’s world of ultra-high speed artillery computing solutions, extremely rapid, constant and unpredictable displacement to new firing positions is ever more critical to survivability.

Would the “bomb” have to be sort of like,

http://en.wikipedia.org/wiki/La_Hitte_system

that shown in the link Andrew i.e. something on its outside to grip the rifling, like the above or lead or something?

Or some of “driving band” in the modern world seemingly…

Do they drop down the barrel in a sort of corkscrew manner then, turning on there way down presumably?

I assume that there was a driving band on the mortar shell, considering several other examples of heavy mine throwers having done the same. I have a book on artillery, and rifled mortars loaded from the muzzle generally do have rounds with driving bands.

If you don’t use a “ramrod” like for a lead ball in a rifled musket. Which I don’t think you do, a shells outer casing is metal usually. The grooves of that barrel look deep, so surely “say a brass driving band” would have to be shaped to allow you it to fit inside the grooves and therefore if dropped in from the top it would turn on its way to the bottom, otherwise how would it fit in, in a manner which would allow it to grip the rifling on the way out.

Just wondering…

Very interesting and good to see things of this kind on FW!

Since it is rifled and barrel is so short than is must have been initiated be separate firing pin – my guess. In one town in Ontario I have seen something similar, but from the other side. When I go back there I will take camera with me.

Since it’s lanyard-fired I’m wondering what the big red button on the side is. A loading safety, perhaps?

Some arrangement to make sure the firing pin stayed retracted during loading would be a very good idea. The very first model Stokes 3-inch issued in 1916 (IIRC) had just such a setup, not for loading (the Stokes was drop-fired), but in case a dud had to be removed from the bore.

As with a conventional small-arms round, sometimes a second hit to a dud primer on a mortar bomb would fire the propelling charge. Not something you want to happen while tipping the tube down and forward and shaking it to get the round to slide out into the No. 2’s hands.

I suspect removing a dud from the German 7.58 and 25 cm Minenwerfers was more like drawing the round on a 19th century rifled muzzle-loading (RML) naval gun. I’m pretty sure there was a specific tool in the gun’s kit for the job.

cheers

eon

Looking at other pictures online, whatever the red thing is it is on both sides. May be one under the barrel too (look at top photo). Guess is they are grease ports to keep the back portion of the barrel lubed in the sleeve it travels in. Grease could be applied to the machined part of the tube at the top to lube the other half. Just my guess at it.

I didn’t see the others. If there’s more than one, I’m sure you’re right, they must be grease fittings, same as you’d find on your car’s king-pins.

A recoil system like that would be straight hydraulic or hydro-pneumatic, so greasing the moving mass contact ares to maintain minimum friction would be a must.

Incidentally, if you look at the arrangement of tube and recoil cylinders, it’s a lot like that on the U.S. 3″ rifle of the WW2 M10 tank destroyer, and the 90mm on the later M36 Jackson.

cheers

eon

Ah, the 76.2mm M10 and 90mm M36 tank destroyers — the former reasonably well-publicized but somewhat under-rated, the latter mostly unpublicized, largely forgotten and grossly under-rated. Both vehicles combined simple construction, good mobility, high speed, ease of maintenance, a high degree of reliability, 360-degree rotating turrets with short reaction times and excellent armor-defeating firepower ( especially the M36 ), although at the cost of high-end armored protection and equipped with open-topped turrets that left the crews ( except for the driver and co-driver / bow gunner in the forward hull ) exposed to airburst and plunging fire.

Two of my favorite AFV’s, among others, from World War Two. It has been a long time since I have heard anyone mention either vehicle in a forum like this. Thanks!

Where did you find this wonderful example? The WW1 museum in Kansas City had one on display there in 2011, but has since rotated its display and placed their Minenwerfer back in storage.

Thankfully a lot of the WW1 artillery donated to US cities in the early 1920s has been slowly removed from the elements over the past 25 years and are being restored by various entities. Would love to have one of these pieces myself…

It’s my understanding that most of the WW1 (also Spanish and Civil Wars) public-display (courthouse lawns and Legion Halls) ordinance was hauled off to be recycled during the scrap drives in WW2. It does seem to be a bit hypocritical to ask housewives to donate their pots and pans to the war effort when there was a couple of tons of steel sitting outside the VFW. Probably the same thing happened to a lot of those clunky old surplus rifles that Bannerman sold for $5 that “everyone knew” would never have any collector value.

I die a little every time that subject comes up.

I try to remain philosophical about it. The destruction of commonplace, outmoded and supposedly worthless old guns, or conversion of fine military surplus rifles to Bubba Specials, serves to increase the rarity and thus the value of the examples that survive unmolested. So it does someone some good somewhere or other.

It is hard for me to imagine, but centuries in the future, an all original Mosin-Nagant rifle will be a prized relic of history.

Take a look at an 1890s Sears or Wards catalog… .58 Springfield rifled muskets with sporterized stocks sold for a dollar and change when a new Winchester 92 or 94 was going for about $14.

And just because Poshboy mentioned the Kansas City WW1 Museum:

http://commons.wikimedia.org/wiki/File:Renault_FT-17_tank_-_National_World_War_I_Museum_-_Kansas_City,_MO_-_DSC07675.JPG

I was pretty sure he was talking about Liberty Memorial, which is what they were still calling it 28 years ago when I got the heck out of Possum Trot. Sounds like the museum has improved a lot since the last time I saw it. Didn’t they park a “riverboat” casino in a pond on top of the hill next door and pump water up from the Missouri so they would comply with the law?

Must you remind us of that shameful episode? 🙂

I think Forgotten Weapons is the one who linked to this flickr.com account: http://www.flickr.com/photos/drakegoodman

The account focuses on German troops in WWI with several photos of minenwerfer guns.

Weren’t these developed to throw glass projectiles containing chemical and smoke agents? The rifling was not so much intended to improve accuracy, but to provide centripetal forces which improved dispersion of chemical agents when the glass projectile hit ground. No precision angular scales engraved on this minenwerfer to facilitate aiming. Same goes for the nebelwerfer series rocket weapons deployed by the Wehrmacht from 1935 on.

Whoa, whoa, whoa, man, back up, back up, BACK UP! This was not a chemical weapon to begin with! The Minenwerfers were originally given to engineer units for use in besieging fortresses, not for throwing nerve gas at entrenched foes! If this were intended to exclusively throw gas around, why bother with the traverse and elevation gears!? I would assume that some sighting equipment could be attached for precision shooting or removed if the gunners decided to go with good old-fashioned trigonometry… And the minenwerfers were made BEFORE poison gas, you [insert random insults here]!!

Andrew –

I know mortars existed for a long time before WW I, Coehorn mortars were widely used in the American Civil War. But after the initial efforts to use smoke and chemical agents via compressed cylinder releases failed in 1915, all sides upgraded their mortars as the delivery vehicle of choice. I am not aware of any pre WW I mortars which were rifled. Rifling and longer barrels were required to throw the long, fragile glass chemical and smoke rounds from mortars with good effect.

Placing smoke and chemical agents where your opponent is, not where your compatriots are, was a driving force behind mortar launching these projectiles. The initial 1915 smoke and chemical efforts failed because wind shifts swept gas released from cylinders across nearby friendlies. Chemical mortars did not require the accuracy of their explosive charge counterparts, but they did offer much better range than cylinder releases with reasonable accuracy.

I wasn’t referring to ALL mortars as a concept before gas… The German Minenwerfers were designed to throw HE shells at fortifications after it was shown during the Russo-Japanese War that heavy howitzers were good at smashing forts that most field artillery couldn’t even dent. Ergo, the rifled barrel made sure that an extremely heavy ammonium nitrate-carbon charge shell wouldn’t randomly fly here and there but slam smack into the pillbox down range and kill everyone inside if possible. Just check the Wikipedia entries! In none of the entries does can I find the phrase “THIS MORTAR WAS SPECIFICALLY DESIGNED TO KILL PEOPLE WITH POISON GAS.” The heavy trench mortar may have been used with gas shells, but the original purpose of the heavy rifled mortars prior to World War I was to smash bunkers and everyone in them to pieces of useless concrete and LUDICROUS GIBS!

I doubt the light 75.8mm Minenwerfer was very effective against any kind of concrete bunkers, but it was probably highly useful against machine gun nests and lighter earth & log type field fortifications, as well as a general suppressive weapon. The 250mm heavy version would have been a different thing, though.

There’s a pretty good article about the 75.8mm Minenwerfer here:

http://www.landships.info/landships/artillery_articles.html?load=/landships/artillery_articles/7_58cm_minenwerfer.html

It does not have references, but most Landships articles are fairly reliable in my experience. What the article makes obvious is that the 7.58cm leichter Minenwerfer n.A. was a pretty direct predecessor of the WW2 7.5cm le.IG 18 with a very similar tactical role.

And oh, nerve gas did not exist in WW1.

The only mortar (apart from the Livens Projector described by eon below) designed specifically to fire chemical and smoke rounds that I know of was the US 4.2″ M1 Chemical mortar developed in the 1920s. During WW2 it was developed into the M2 Mortar, which fired only HE and smoke in action, but was organizationally still part employed by the “Chemical mortar” battalions.

http://en.wikipedia.org/wiki/M2_4.2_inch_mortar

Given the discussion on gas use from mortars in WWI I thought I’d share the information I have on the subject in case anyone’s interested. It’s mostly on British techniques so I’m afraid I can’t really help on the subject of Minewerfer gas shells. For what it’s worth I read they mainly delivered gas by cylinder release and conventional artillery.

Gas Warfare in the British army was primarily handled by the Special Brigade of the Royal Engineers, the RA got in on it too but I’ll get to them later. The special Brigade was the unit that planned and carried out gas attacks on the western front, by May 1916 they numbered 5,500 men and included companies of Stokes mortars and Livens Flamethrowers, the Livens projector was added to the TO&E later (busy man Livens)

The Stoke mortar companies were in action on the first day of the battle of the Somme until its conclusion; at first they only had smoke shells available due to issues in the production of the SK tear gas shells. The Stoke units laid smokescreens ahead of the infantry advance in the sectors they were deployed to and were apparently very successful, though hampered by the limited availability of the red phosphorous smoke rounds.

While the Somme offensive was ongoing the Special Brigade converted some units from the Stoke to the older 2 Inch “Toffee apple” mortar. They had managed to create a rudimentary gas shell by filling the cast iron “toffee apple” shell with the white cross gas Phosgene/Chlorine gas mixture used for cylinder attacks. These were in use from the 2nd of September and were very useful by all accounts as the shells had a high capacity and white star was both highly lethal and quick to disperse, as a result White Star attacks were used to incapacitate German defenders immediately before an assault went in.

The SK tear gas shells for the Stokes mortars finally arrived and were first used at the battles of Flers and Thiepval on the 24th September. SK gas was persistent and could last up to 12 hours so the Stoke units had to be more careful what areas they targeted, Stokes generally used SK to drive Germans in dugouts into the open where they could be hit by HE or to deny ground to the Germans.

By 1917 the Stokes the British could fire every type of gas they had from the Stokes mortar, these included “White star”, SK and a gas called PS or Chloropicrin. PS gas wasn’t as lethal as phosgene but it did have the properties of both a tear and lethal gas, in addition to this the gas was found to penetrate German gas masks (apparently these were an item to be brought back on trench raids so that gases could be tested against them). Once this was found out it was standard practice to fire PC and “White Star” together, the PC would force soldiers to remove their masks and then the “White Star” would do the rest. On top of that you had your garden variety HE, White phosphorous and airbursting thermite shells.

The 4.2″ mortar served well into the 90s in US formations, somewhat altered as the “M30 107mm,” although it’s been replaced by a 120mm mortar, the M120, that’s lighter (less than half the weight), longer-ranged, and has a higher rate of fire. The M120 is of Israeli and Finnish design (SOLTAM/Tampere Oy). I did fire the four-deuce a bit but never shot the successor.

As Euroweasel points out, it was originally a chemical weapon, but bear in mind that in the US forces smoke and WP were also “chemical” weapons along with the WWI war gases (and their inter- and post-war variants). The US unilaterally disarmed its offensive bioweapon capability in 1969-73 and offensive chemical weapon capability production in 1969, destroying all stocks of CW from 1991. The four-deuce had long since become an infantry weapon, like other mortars, but due to its size and weight it’s not man-portable but goes to war in or on or towed behind a vehicle.

The 4.2″ mortar is rifled. It has 24 lands and grooves with a RH twist, so it’s a very different animal than the Minenwerfer’s rifling (looks like 6 lands and grooves, LH?). Contrary to popular opinion, a fin stabilized round can be as accurate as a rifled round, but the rifled mortars (both the M30 107mm and the 2.8Cm minenwerfer) can have a flat base round, with more interior volume for filling. That’s obviously useful whether the filling is HE, WP, or some chemical agent.

Like everything else in engineering, there are tradeoffs….

Interesting you should mention the SOLTAM / Tampella mortars. When I was in the service, we used these in both 81mm and 120mm calibers ; we also had the SOLTAM 60mm mortar for portable infantry applications. They are all excellent, well-made, accurate and reliable weapons that, as you have pointed out, are relatively light compared to their rivals, yet very strongly built and capable of high sustained rates of fire.

Early on, everybody who used chemical agents (mainly phosgene at that time) was looking for a way to isolate the liquid “gas” from the steel or (often) cast-iron shell-casing. Phosgene is fiendishly corrosive stuff, and attacks iron alloys like termites go ga-ga over a wood-frame house. A leaking phosgene shell is emphatically not funny.

Everybody first used shrapnel shell casings, because they had a separate screwed-on nose that allowed a canister of liquid chemical to be inserted with a burster charge under it, or inside a hollow tube in its center (“doughnut” cross-section), and then the cap with fuse could be screwed on.

Later on (mid-1915), both sides developed ways of coating the inside of a standard HE shell casing to protect it from the liquid. The Germans coated the inside with a paint electrolytically. The French blew very tough blue glass in through the filling/fuze hole at the nose tip. Either way, the gas could then just be run in, and the fuse screwed in last with its burster, with an asbestos seal washer at the top of the threads.

The drum-launching gadget was called the Livens Projector;

http://en.wikipedia.org/wiki/Livens_Projector

Which was basically a really primitive mortar, smoothbored, that launched a “drum” about the size and shape of a scuba tank with a burster, filled with 30 pounds of phosgene, mustard, or other chemical agent in liquid form.

Livens Projectors were designed for mass fire. A ditch was dug with a 45-degree angled side, parallel to the front. The projectors, dozens or even hundreds, were laid in it, pointed toward the enemy, and dirt tamped over them. Each one was loaded with a guncotton charge under a drum, with an electric detonator wired up to the propelling charge. They were connected to a blasting box or two, and on signal, the sergeant cranked said box, and up to a couple of hundred drums with 30 pounds of gas each went WHOOMP in the direction of the enemy, their burster charges firing on impact and releaseing what amounted to a “cloud” or “beam” gas attack concentration right on top of the enemy position.

One nasty attribute of the Livens was that, except when fired in huge numbers at once, its dull thud was often “lost” in the general low rumble of artillery fire, etc. Which meant that unlike when an artillery group (divisional sized or better) opened up, the enemy didn’t generally hear the BANG of the “guns”- and thus their first notification that a gas attack was underway was when it hit. Right on top of them.

Once they’d gotten hit with it, the Germans quickly developed their own version of the Livens, but its cylinders only held about half as much gas. As Ian Hogg once said, there’s nothing that gives you a healthy respect for a weapon’s destructive power faster than being on the receiving end of same.

Source; Gas by Ian Hogg. Ballantine, 1975.

cheers

eon

Nebelwerfers were originally designed to fire gas shells, the number 40 one resembles this I think.

Like it, I saw something on an episode of T.V’s future weapons called Dragon fire which was a cross between a heavy mortar and a howitzer sort of like this only it was robotic loaded itself with a 120mm mortar nice work.

4.5kg shell 1300m…

http://en.wikipedia.org/wiki/Davy_Crockett_(nuclear_device)

Someone wants to re-engineer one of the above in my opinion, to fire a 155mm 46kg shell 500m max

One lucky guy lugs a shell, have the redesigned launcher be as much “Congreve” as possible i.e. not alot to it.

Come across a baddie round the corner, set up the launcher pop on the bomb, lob it over and duck, give the fellow who it lands on a nasty shock.

Just two cents worth on “driving bands”. There are two uses for a piece of metal around a projectile. One is in a breech loading weapon where a band of metal softer than the projectile [usually something like brass or aluminum] is used to engage the rifling instead of the projectile itself [which is usually steel]. This prevents the steel projectile from scouring the rifling out of the barrel. In a muzzle loaded mortar the band of softer metal acts like the base of the “Minie Ball” of the civil war, it almost instantly expands to seal the projectile to the barrel so that the propelling gases don’t leak past. The leak would cause a small loss of velocity but more important it would, at random, jam one side the projectile against the barrel while the gases whizzed past on the other creating an unequal drag and ruin the weapons accuracy. In both cases the “driving band” doesn’t actually drive the projectile, if it weren’t there the projectile would still be driven out of the barrel by the propelling gases. A more accurate name would be “engagement band” or “sealing ring” or some such but “driving band” does sound much more He-manly don’t it? PS: does anyone know what the oh-so-literal Swiss call their metal rings?

W. Fleetwood perhaps you could clarify something for me. When you say “the driving band engages the rifling in a breech loader” this results in the steel case of the shell turning, does it? Therefore the band would need to be attached to the shell, correct? It doesn’t merely seal the projectile in the barrel, otherwise what is the point of rifling unless that is the point you understand it’s purpose in an artillery piece is to form a seal not to induce spin. In relation to what you say about the Minie bullet, the hollow cavity in it’s base makes it expand into the rifling. So in regards the above mortar, the base of it’s shell would be as such, would it? I.e. Allowing it to fit in the barrel from the top, unlike if it had a driving band of a larger diameter than the bore with the rifling. In which case, say this mortars shell had a lead minie bullet style base… Upon firing this would expand and engage the rifling forming a seal, now would it also turn the projectile as a consequence via it being attached to the shells case. If so, it could be described as a method for driving the projectile through the rifling rather than the barrel hence the term in my understanding.

That La hitte system turned the projectile in the barrel, so I assumed a driving band was simpler method to achieve this via conventional rifling with a steel projectile while producing a seal. Did the la hitte projectile have a Minie style base, one wonders.

In essence, if either the band or base were not attached to the shell they would engage the rifling creating a seal keeping the gas behind the projectile without turning it i.e. only they would turn around the shell effectively being a wad, which isn’t what your saying is it.

They do impart spin on the projectile, as well as creating a seal.

The shells for this mortar by the looks of it had a driving/rotating band which fitted the grooves in the barrel on the outside of the case.

http://www.passioncompassion1418.com/decouvertes/english_fusees_munitions.html

Which I would imagine, would make them turn when dropped down the barrel which is perhaps why they needed a firing mechanism i.e. they wouldn’t drop down fast enough particularly in a short barrel to hit a fixed pin at the base with adequate “umph” to detonate it.

I also looked at a video,

http://www.youtube.com/watch?v=0_Z99RgHao8

showing a modern 120mm rifled mortar which are also lanyard fired and there does appear to be a delay longer than if it was smoothbore from popping the round in the top of the barrel to the clunk as it hits the bottom which perhaps means it goes down in a spiral manner.

http://www.gd-ots.com/efss_120mm_RifledMortar.html

The rounds driving band does appear to be shaped to fit the rifling grooves, in the above picture.

For Mr. Doughboy: sorry, I was making an effort not to be the long winded know-it-all my friends occasionally {Okay, often] accuse me of being. So, the long winded version: the “driving band” or ring of metal that is slightly larger than the main projectile of an artillery round or tank main gun. Upon firing it is that band that is forced into the rifling of the barrel rather than the main body of the projectile. The band then seals the propelling gases to the rear and when the band is turned by the rifling it turns the projectile without that projectiles main body contacting the barrel. Probably the extreme examples of this were the German “squeeze bore” anti-tank rifles of WW2. However, even if the barrel isn’t rifled, such as a mortar or smoothbore tank gun, projectiles will still have a ring of metal that folks will call a “driving band”. That band serves just two purposes, sealing the gases to the rear of the projectile and preventing steel to steel contact. I hope this is a little less midnight-at-the-keyboard than my last.

I understand entirely, generally old bean.

Most insightful, I thank you sincerely all round.

I have learned something overall, it’s all good : )

The driving band is sometimes referred to as the “obdurating band” as well.

Video of mortar in action: http://www.flickr.com/photos/drakegoodman/13202124874/

Oh that was so good 🙂