Rock Island is selling these two Boberg pistols as part of a Lot 1089 in their upcoming Regional auction on February 14th, 2019.

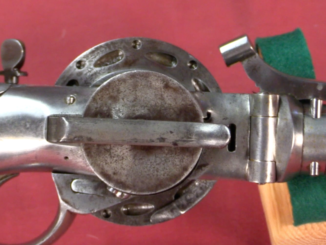

Arne Boberg founded Boberg Arms in 2009 and released his first pistol in 2011, the XR9-S. This was followed by the longer XR9-L, and then the XR-45S in 2014. The conceit of the Boberg pistol is basically that of the Bullpup rifle: maximizing barrel length while minimizing overall length. To this end, Boberg used an unconventional system of pulling cartridges out the back of the magazine rather than pushing them forward, allowing about an inch of extra barrel in a given pistol. The resulting feed system is a bit complex and very cool, and reminiscent of the old British Mars pistols. It is not without its faults, though, and the lowest priced Boberg pistols were over $1000 retail, which significantly limited their sales in a concealed carry market awash with good options at half the price. In 2016 Boberg sold the gun to the Bond Arms company, which markets is today as the Bond Bullpup. Original Boberg production guns have, thus, become collectible items for those interested in unusual handguns.

Automatic correction misspelled “concept” as “conceit.” That aside, this is a well-meaning concept gone horribly wrong due to production costs. I wonder how anyone thought the Browning style compact pistols (both in blow-back or tilting barrel locked variants) were too bulky for concealed carry… to say nothing about the PPK or even the Beretta Cheetah, both of which are pretty good for “get your mitts off me” encounters.

Yeah, like if that one inch in length difference mattered. 🙂

Finally, if you need as long barrel as possible AT ANY PRICE then copy R-23 revolver cannon (obviously together with its ammunition designed to work together with this front-loaded revolver cannon): https://en.wikipedia.org/wiki/Rikhter_R-23

Oh-lala,….. I have to look at Valka.cz for details. True, barrel is not very long. I figure with these high flying planes and ambient temperatures around -70deg C there must be effect into barrel material (partial reduction of strength).

“Valka.cz”

After you end, you might read http://www.bratishka.ru/archiv/2007/8/2007_8_17.php starting at line ГОВОРЯ о создателях советского авиационного артиллерийского вооружения…

I think conceit works ok if you use the definition ;

«Something that is conceived in the mind; a thought»

Though it might be the autocorrect gremlin at play .

Conceit is a perfectly cromulent word here – in this case, meaning “an organizing theme or concept”

Co-worker bought one of these in 9mm a few years ago for his back-up / off-duty carry. Really neat little pistol, but it was VERY finicky about ammo. The pistol came with a list of recommended factory loads and while it was a decent selection, all of the loads were lighter bullets, nothing over 125 grains, and our issued ammo wasn’t on the list. We shot some duty ammo anyway and confirmed it wasn’t going to work. I suspect the magazine did not have a typical follower so as to make it easier to clean out the un-burned loose powder that gets dumped out when a case is yanked off of a bullet.

Still want one.

I cannot see in Ian’s video how it works, but I believe you are right – it does not have a follower/ lifter.

Bond Arms now says that you have to be very careful what 9 x 19mm ammo you feed their version;

https://2a6bxd1ukbld4yxdd2itw42x-wpengine.netdna-ssl.com/wp-content/uploads/2017/06/BP-Ammunition-Notice-9-25-2017.pdf

Myself, I tend to shy away from weapon systems that are a bit too refined in their tastes.

cheers

eon

“shy away from weapon systems that are a bit too refined in their tastes.”

By browsing for more data I encountered article suggesting that XR9-S might give were unpleasant malfunction, in worst time possible, see 7th image from top:

https://www.luckygunner.com/lounge/one-fatal-flaw-the-boberg-xr9-s-9mm/

i have 5 bobergs xr45 onyx serial # around 40 bought new never fired never even loaded with ammo. i also have 4 xr9s might part with xr45 and 1 xr9

How much for the XR45S?

As I said I am looking for one.

Still got ’em?

So here we go: Bobby is FW already!

And, what else to expect. Invent, patent, make and mainly sell something like cost lots of money. It’s like pixxing against the wind. Not a chance to win with something so unusual unless you match price with ‘primitive’ Glock at which point you go bankrupt. Great lesson for inventors, worldwide.

It helps if your invention actually results in something that has a noticeable improvement over existing designs, in one way or another, and *doesn’t* simultaneously fail to provide any significant improvement in cost, performance, etc., while also bringing in new flaws that your competitors do not share.

Yup, if you want to be a successful inventor, you need to create a successful invention. “It works significantly worse and has no major advantage at all, but it’s way more expensive” is not “successful”, no…

Yet, I have to admire Boberg’s “pioneering” spirit. 🙂

When I consider his possible frame of mind – laid off with existential threat, he had to do ‘something’. On top of it he demonstrated to his former employer what they lost in him. I was in similar situation one time.

““pioneering””

After some thinking I concluded that Boberg achieved similar feat (high barrel-length-to-overall-length radio) but in much different way to… Dardick. Consider namely DARDICK HANDGUN SERIES 1100, see 3rd image from top:

https://modernfirearms.net/en/handguns/handguns-en/u-s-a-semi-automatic-pistols/dardick-eng/

designed yet in 1950s, though DARDICK HANDGUN SERIES 1100 is fatter, due to rotor (? I am not sure about correct name of that element ?). DARDICK felt into oblivion due to time-consuming procedure of loading cartridges into magazine and using untypical (and unorthodox by 1950s U.S. standards) ammunition, but still have bigger capacity (11) than Boberg.

Of course, even Glock is willing to change given enough reason;

https://www.thefirearmblog.com/blog/2017/09/24/new-glock-46-rotating-barrel-lockup-german-police-trials/

Incidentally, the final production model has 1911-type ambidextrous thumb safeties, admittedly mainly for purposes of field-stripping. On the 46, you no longer have to fiddle with the trigger to remove the slide/barrel group.

Hm. Glock has finally come up with a 9 x 19mm I’m somewhat interested in.

cheers

eon

“reason”

Actually Glock 46 according to https://modernfirearms.net/en/handguns/handguns-en/austria-semi-automatic-pistols/glock-46-2/ is response to Sachsen-Anhalt police request, to replace SIG-Sauer P225 automatic pistols.

This was a surprise to me when reading about it first time. I thought the PX4 was the apex and ‘end of all rotaries’. Sure, there are solid reasons about keeping them (energy attenuation, accuracy…). The product cost is higher than with flappers though. At least on civilian market the PX4 always costs more than a Glock.

With that is of course connected question why Beretta gave up on it.

“end”

Uhm, not, for short-recoil/rotation automatic pistol crafted later than said Px4 see Q-100: https://modernfirearms.net/en/handguns/handguns-en/slovakia-semi-automatic-pistols/q-100-eng/

Also although timeline-wise earlier than Px4 I suggest to NOT underestimate GSh-18, which is lighter than Px4, yet has bigger capacity (assuming default magazines for both)

Funny detail: founder of Grand prix pistol company had offered his product to Slovak military. Guest what: they chose CZUB and Glock instead. This is how to treat your own, Slovak style.

Glock 46 seems the continuation of tendancy of using nearly a century old take down method of dragging the barrel with slide fore and up through the frame rails, first used in Mauser HSc, moved on with Vz52, HK4, HK9 and temporary stopped but reinvented by Bubits on BB6 and continued with new Mossberg pistol and Glock 46 with a difference that containing frame stop and take down key piece at back. Fredrich Dechant the inventer, seems managing the rotating barrel take down through a very reasonable method after trying and patenting a few childish construction. Through this take down, the striker spring losts its power as its back support being taken away and the need of dry firing before disassembly is out.

lt is said civilian purchase of Glock 46 is not possible.

Another later article said that a civilian version will be available later this year from Glock USA.

As for “dragging the slide and barrel off the front of the frame”, there was a sound reason for that from the start. Namely, that self-loaders with bolts or slides that could be removed backward could sometimes fracture their stops and be projected forcefully backward on firing-right into the shooter’s face. The Schwarzlose Standart and Mauser C/96 both had this problem, the Mauser in particular as all that keeps its bolt in the barrel extension on recoil is that single little block the recoil spring bears against. If it shears, say hello to an eyeful of DWM steel.

Later designs are not exempt. The Kimball retarded-blowback pistol in .30 Carbine, build much like a Colt Woodsman .22 rimfire, had a short slide retained by two stop-blocks machined into the rear of the frame. If they broke, the slide would be launched straight back at considerable velocity. Due to inadequate heat-treatment plus sheer operating stresses, most Kimballs still extant have at last one stop block either cracked or broken entirely off.

As you might expect, it was John Moses Browning who first came up with a slide/barrel group that could only be removed forward off the frame, precisely to avoid this kind of accident, with his Modele 1900 automatic for FN. A feature carried over to all of his subsequent pistol designs.

Ironically, or maybe predictably, during WW1 the German Langenhans 9 x 19mm pistol, externally an FN 1900 “clone”, had a powerful recoil spring to allow the blowback action to accommodate the powerful 9mm Parabellum cartridge. To ease loading, a lever at the top rear of the slide allowed the inner bolt to be disconnected from the recoil spring. With wear, this lever could flip over in recoil- and the bolt would enthusiastically try to kill the shooter, rather like a Ross rifle bolt.

(NB: The Ross rifle bolt hazard is not a myth; I have dealt with Ross rifles, both military and sporting, and never found one that could not have the bolt assembled incorrectly, resulting in firing in the unlocked state.)

The forward removal of slide and barrel on an automatic pistol might seem “old-fashioned”, but in actual shooting it’s considerably safer than the other setup ever was.

cheers

eon

Thanks Eon… But what l wanted to say was, the new popularized take down process needing a slight forward move of slide and barrel and up to be disengaged, instead of more popular direct forward and off. The fore movement of disengaging slide in this two way movement application is so short that, the striker in the slide can not get enough compression for a discharge as precluding the necessity of dry firing beforehand… However,

both Mossberg and Glock 46 also ensure this handicap as getting the striker spring functioned away.

“Great lesson for inventors, worldwide.”

I would rather say entrepreneurs. Great question is how to convince buyers that product is worth buying.

Partial answer to how to convince buyers that product is worth buying:

Produce a product that actually is worth buying, and doesn’t cost MORE for WORSE performance, while offering no significant advantage IN ANY RESPECT.

“maximizing barrel length while minimizing overall length”

Barrel long, pistol short?

Maybe in order to do so, other over 100 year old design might be used, namely Schwarzlose 1908: https://unblinkingeye.com/Guns/SLZ/slz.html

blow-forward, works with 7,65 mm Browning [.32 Auto], would need further experimentation to detect how it would cope with heavier cartridge. Also more importantly how does rifling affects dynamics of such system. How it would work with hexagonal barrel bore? How it does work with few big grooves vs a lot of small? Could it be used with progressive rifling?

Finally I am wondering if blow-forward could be cross-breed with Gas Bremse principle (as found in Steyr GB)?

Not sure if gas break would work, because… The bullet moves the barrel forward via the rifling, so you’d be preventing the barrel moving… While the bullet is travelling.

The Schwarzlose does/could end up with a similar result though, from memory I.e. The extra barrel length, but in blowback.

Did the Mars have the bullet pulling problem. Seem to remember having a similar conversation before…

Twin mag, cross of this and your idea; forward mag infront of this ones position, operates as now, but with blow forward also, fires as per but then blows forward slide catches up loads again fires, moves back loads boberg style; double tap.

Mind you I am drinking wine.

Blowback cals only as that would likely be complicated enough.

Are AN94’s U.S legal, in principle as a semi auto double tap lark via only pulling the trigger once? No step on snek, all that; sales.

More first chance hit probability, in the unlikely event it fires a round he he.

Blam! Blam! Make it so Russian people.

Blam! Blam! Yes but…

Blam! Blam! That will sell.

Base the op in Bulgaria for exports, or something; stupid U.S Gun laws, mini guns if you can afford it.

Well, thats competition; not. A home grown fuckin mini gun.

You could probably get 2,500 with a water cooled version of my Winchester Gast gun, no; hippies.

Brewing a massive Tsarse bomber here, no food 3 bottles of claret; asking for Novaya Zemlya tommorow.

https://youtu.be/HZ1TQYjCwYc

Sorry “Denmark” at a push, Russia maybe… I released “toxic” gas, wind is going your way; sorry. Burp, sorry again.

“Tsarse bomber”

What do you understand under that term?

“preventing the barrel moving… While the bullet is travelling.”

Please note that pressure is NOT constant during whole bullet travel through barrel, so in order to making it work, it would need to be such balanced that at certain point, when bullet is still traveling down the barrel, braking force becomes lower than barrel pulling force.

Yes I can see that, I could soon as I posted it; well only one way to find out have you got a drill and a Schwarzlose I haven’t. Make a estimated guess… You could always weld bits onto the slide to increase its weight, so a welding machine also.

Oh no you could’nt… Er, well you could make the barrel heavier; welding required and a saw now.

I reckon you start in the area of the GB’s, after making the barrel similar in weight to its slide… This is probably going to take longer than initially expected.

Er… How about a reverse… Luger… Toggle… I’ll need to draw it quickly.

Blow foward still, but the barrel now hits the knee thing.

I’ll think about that more anyway, thanks for the notion; probably be a 3,000 comment one though so, I’ll desist from sharing everything I think of in between.

Barrel has to move (rotate), it has ho choice since it is dragged back with slide. Now comes the trick part. Should it rotate clock-or-counter-clockwise? Bullet spin reaction into barrel tends to turn it opposite to sense of rifling. I once in back looked into it and found there was not clear uniformity; some (majority) rotate against the reaction and some with. To me, this is great opportunity to dump and much slide momentum as possible so that user feels less of it in his hand.

Clever… You’ve lost me, he he.

“Did the Mars have the bullet pulling problem.”

Yes, that was solved by using heavy crimp, see photo: http://municion.org/mars/450MarsLong.htm

Oh right thanks, some Mars rounds were bottle necked did that help?

It probably helped in two ways.

First, necking the original .45 round down to 9mm or 8.5mm meant going from a 220gr bullet to 156gr or 139gr. The reduction in caliber isn’t all good, because the crimp circumference also reduces linearly with diameter, but the mass reduction is (in this case) faster than linear, so the inertial force trying to extract the bullet reduces by more than the crimp strength does.

Second, the smaller caliber bullets unsurprisingly had lower momentum (and thus recoil), probably yielding less violent operation. (Though I’m not certain that the moving parts were the same mass on different-caliber Mars pistols.)

A third potential reason (which turns out not to apply in the case of the Mars) could be the fact that bottle-necked rounds generally headspace on the shoulder, and may be crimped as desired, whereas the straight-walled rimless cartridges we think of as conventional for autopistols (9mm, .45ACP, etc.) are designed to headspace on the case mouth, which limits the depth of crimp so the case mouth isn’t too tapered/rounded to reliably seat on the square step in the front of the chamber.

But of course there’s ways to headspace without a shoulder or squared-off case mouth, the most obvious choice being to headspace on the case rim. (Typically with a semi-rimmed case, but you can also design an extractor to headspace a rimless case off its extractor groove.) The Mars pistol in .45, on the other hand, did have the case severely crimped with a chamfer, such that there was no flat end to seat in a normal chamber, yet it still headspaced on the case mouth. The front of the chamber was tapered to match the crimp angle.

I’d call this a very unconventional choice, but it’s important to remember the Mars design dates to an era before we knew what “conventional” autopistols and cartridges would turn out to be. At the time, John M. Browning was still designing semi-rimmed cartridges, and it would be 4 years till Luger would introduce 9mm, the prototypical rimless, case-mouth-headspacing cartridge.

The Mars pistols all used proprietary cartridges from what I recall, so if the cartridge had separation issues, the spec could easily be changed to use a more robust crimp.

Cheers.

Blow forward guns seem to have unpleasant recoil. Probably something to do with conservation of momentum and that equal and opposite nonsense.

Whys that then??

Felt recoil is discussed in Impressions and Handling chapter of article I linked earlier: https://unblinkingeye.com/Guns/SLZ/slz.html

Opinion cited vary greatly.

Try it with gas, why not. Browning used a hammer, who needs a computer; if you have the gun, he he.

The barrel has to move forward the length of a cartridge before feeding can begin, that is during the extraction and ejection phases of the cycle of operation, a very short time. It pushes off on the frame which pushes on your hand. This is in addition to normal recoil from the bullet and burning powder leaving the barrel.

Oh right… I can, see that; duration, lark.

Thanks.

Ian’s take: https://www.forgottenweapons.com/early-automatic-pistols/schwarzlose-1908/ YMMV

Well you forget don’t you; or I do, thanks.

Jager pistol… Is what I was on about.

Got there finally, the WW1 pistol.

https://www.forgottenweapons.com/ria-the-jager-pistol-and-its-complex-reassembly/

Harder to find here than it used to be, via the pistol menu.

J.Janissaries… Meh. Jager.

“Jager pistol… Is what I was on about.

Got there finally, the WW1 pistol.

”

Now when you provided less corrupted name, I am able to detect that you means Jäger-Pistole.

Bottle necked 22. Tcm, 7.62×25, 32.naa cartridges might help in regards the bullet getting pulled from the cartridge; as the mag spring/lower case, would maybe snag less on the bullet as it would perhaps be in contact with the case more at the moment of potential snagging. And then the bullet would also be a bit lighter… 22. Tcm would maybe benefit more from a longer barrel also, for velocity; and the extra inch but so as to make it the same length as normal pistols, but with 2″ more barrel.

I liked the idea of this pistol, when it came out…

“22. Tcm, 7.62×25”

Keep in mind these cartridge have bigger overall length that 9×19 Parabellum, according to municion:

9×19 Parabellum – 29,26 mm

.22 TCM – 31,90 mm

7,62×25 pattern 1930 – 34,69 mm

I do not know if there is enough place inside Boberg to transfer these cartridge, however if you wish to have bottle-neck cartridge, I would suggest using 7,65×21 Parabellum (.30 Luger in U.S. parlance), as it is actually bit shorter, at 29,11 mm, than 9×19 Parabellum.

Go with that then, good suggestion; have we solved the problem, ring Bond Arms.

have we solved the problem

Wait, how you were to rework big enough sample (no less than 30 examples) XR9S firing 9×19 Parabellum to firing 7,65×21 Parabellum and test it gathering enough relevant data, like for example MTBF and process it, in so short time?

.22 TCM was designed for 1911s, so it has essentially the same length as .45 ACP and .38 Super. I’m sure the XR45S could be adapted to it.

As to whether it solves the problem — well, there’s exactly one commercial loading available (or two if you count .22 TCM-9R, which is the same cartridge loaded to a shorter overall length to fit in 9mm magazines), so it will certainly alleviate the problem of having to remember which loadings are okay and which will come apart. It will either work or not. I do think it would work, though — with 40gr bullet instead of 124gr or 147gr in 9mm, there’s a lot less mass pulling on the crimp.

Regarding .30 Luger, I do like the cartridge (I’m a sucker for bottlenecked pistol cartridges of all sorts), but it’s ballistically underwhelming, and the US market is reluctant to embrace either uncommon cartridges or those with poor terminal ballistics — combining both in one is no recipe for commercial success. I think the only thing that would sell worse (in the US market, at any rate) than a $1000 9mm pocket pistol that requires careful ammo selection to avoid spontaneous cartridge disassembly would be a $1000 pocket pistol in 7.65 Luger, no matter how flawlessly it functions.

A bottlenecked cartridge derived from a straight-walled parent case frequently has a higher max pressure, e.g. compare parent cartridges .40 at 35,000 PSI or 10mm at 37,500 PSI vs child .357 SIG at 40,000 PSI. This helps compensate for the lower bore area, which otherwise makes necked-down cartridges require longer barrels to realize their potential.

With the Luger Parabellum cartridges, the ancestry is the other way around. Parent .30 Luger is limited to 28,000 PSI (SAAMI) or 2350 bar (CIP), while the child cartridge 9mm Luger is up to 35,000 PSI (SAAMI) or 2350 bar (CIP). With the same (or in the US, even lower) pressure, and 25% less bore area, it’s poor enough from the 4.7″ barrel of the 1900 Parabellum, and I’m sure it would prove completely uninspiring from the 3.3″ barrel of the XR9S and Bond Bullpup9.

“XR45S”

Ok, this give another possibility, namely using .400 Cor-Bon

https://en.wikipedia.org/wiki/.400_Cor-Bon

bottle-necked and head-space at shoulder, bigger pressure that parent cartridge, it might work.

“.38 Super”

Wait, maybe this cartridge, is just answer, should fit lengthwise into .45 version of Boberg and head-space is at rim, so you might crimp as you wish.

I visited Boberg in White Bear Lake MN several years ago (it’s a suburb N of St. Paul) while working at another MN firearms accessories company (think green lasers). It was in a little office/manufacturing park, and you wouldn’t suspect what went on inside. As I recall, they made the slides themselves, but had the frames made elsewhere. I could be wrong.

I was impressed with the compactness of the shop and the number of people who could manufacture and assemble a functioning pistol. A woman I think was Mrs. Boberg showed me around, and I left with a frame for the longer 9m model, which we were trying to build a laser for, and thought to myself ‘cool pistol, but the price point is too high’. Not surprised Bond ended up buying them, he understands the model for keeping odd pistols selling, with his derringer line.

The PRICE was too high. Price point refers to a relative industry

price mark. Prices can be above or below this mark as determined by each seller.

I think this is worth remembering in regards unusual pistols; got a safety if you want it, in a military style; doubles as the dis assembly mech.

Should combine as much as possible off this website I think, to make ze ideal gun; which would not be modular, instead you’d have a series of perfect guns; which may share parts, but not be a F35.

https://www.forgottenweapons.com/north-korean-type-70-pistol-at-ria/

F35 fighter which has stretched the modular idea too far.

Uk military style at least, but military guns should have safeties to try and avoid accidents in training.

Very tired people make mistakes; not me, but it does happen… So a safety is good. Your dead even if your own side shoots you, with Army recruitment down; accidents won’t help, look shoddy.

Well I did drop a rifle in different circumstances, but it never went off as it wasn’t loaded for a start; and the radioactive sight never broke which shows they were tough with the weight of that rifle.

So its the same thing: they knew they’d be dropped now and again.

What is radioactive sight?

“dropped now and again”

Testing military-arms for being drop-safe is nothing new, as historical tidbit Belgians tested their rifles yet back in 1886

https://www.forgottenweapons.com/belgian-1886-rifle-trials-report-translated-to-english/

for being able to survive being dropped from height of 1 meter, although it was testing if it was survive, rather than if it would fire with cartridge in chamber.

Susat, think it had a tritium element that was dead… By then, point being it didn’t smash.

Your a rubbish spy, that stupid big fat thing on top of the gun; Sa80.

“rubbish spy”

Before you promulgate such hypothesis, please read about OPERATION ACOUSTIC KITTY done by CIA and its inglorious end.

“make ze ideal gun”

What does ze ideal means? What evaluation function do you use to compute how close to ze ideal is given pattern?

Interview with Arne Boberg. https://www.youtube.com/watch?v=4jIEutsX8Bk

Thats a lovely wee gun.

Whats that computer program he uses, I can’t do that with paint “which is much better than a pen and the back of a fag packet” ??

Why does nobody use that WW1 idea, of design were you clip pistol parts together; forgot the name… You don’t ream stuff etc, is that because of computers?

“wee gun”

I do not know what is wee gun. Can you explain?

German gun, arse… Mae, nope. Ww1, didn’t weld it; pistol.

Austrian. It was a different way off assembling a pistol; was on here. Ww1 pistol. Mr Janissaries, no.

Use your bigger melon to compute.

Explanation unclear.

Jager pistol.

Scotch; small I.e. Wee. English; tiny.

Also means piss “wee” pee… Which is probably confusing the issue.

But not related… Directly.

Sevastopol?

No, be here all night.

In response to whoever mentioned blow forward.

I had a very serious look at blow forward about a dozen years or more ago.

By definition, blow forward is plagued with horrible recoil.

It only gets worse if you add in gas assistance.

Conventional gas operation (shoving the bolt carrier and bolt backwards) can reduce felt recoil, because the acceleration of the bolt group is reacting against the bit of the gun with the stock on it, and shoving the stock forwards.

Doing that with blow forward, makes recoil even worse!

“makes recoil even worse!”

I did mentioned combining blow-forward with Gas Bremse, not typical gas operation.

What does: “Blow forward guns seem to have unpleasant recoil. Probably something to do with conservation of momentum and that equal and opposite nonsense.” BP’s comment, mean Keith; here… Mean?

Those Bobergs are really nicely made. That’s a premium internal finish.

I’m guessing that he was probably selling at a loss.

There does seem to have been a strange time when premium quality sold in mainstream volumes, with S&W revolvers.

Since then, guns that an average worker could afford, might have had ok functionality, but the finish on the visible parts looks like it has been done on a belt sander, and the hidden bits are rough as feck.

Small batch products, of individual design and at boberg standard of finish, want to be selling at close to us $five figures.

I’m glad that the design is still going.

“selling at a loss”

IIRC this was also case in case of Repetierpistole M.7

^^^^

Big hint; if you get those pistols at less than five figures each, oil think that you are getting a bargain.

I think…

Damn the autoincorrect

The difficulty with bullets pulling out is due to the much faster acceleration on the recoil stroke.

Compared to the much gentler acceleration under spring pressure on the feed cycle.

In big, dangerous game rifles, it is an advantage to have a long thick case neck, to retain the big heavy bullets against pulling out due to recoil in the magazine.

One of the biggest and heaviest magazine rifle rounds, the .500 jefferies/Schuler, had a decidedly short neck. Before the. 460 weatherby, it was the largest of the magazine rifle big game rounds, but perhaps not the best designed.

Would bottle necked .30 Luger help here then or not; we’ll take your word for it? Or I will.

Or should they nock up a special case, based on .30 luger with attributes of said neck; if possible, excepting this would be pro… proprietary ammo; and thus be bad for sales. Probably.

As far as I can tell from just watching Ian’s video this is a uniquely original creation; which makes Mr Boberg 100% more original than 98% of the people who’ve make a living out of the creative arts industry; and from user comments on the gun, you did a right good job making the things and all.

Back in John Browning’s time that originality would have resulted in the likes of Colt buying any patent he had on this gun. If everything was already patented (see Ian’s last but one video) then bad luck Mr Boberg.

Well I like the gun, but if it pulls bullets out of the cartridges; I don’t blame him for not seeing this prior, but lets try and solve it.

Because by doing so, we can use the best attributes of it; more velocity via the same overall length for example.

I know it is supposed to work with certain brands, but that isn’t the point; theres potentially 2″ of extra rifled barrel there, in relation to it being the same length of other guns, would .357 magnum rimmed be better; so forth.

28.96 mm overall length .357 sig. Stuff.

“.357 sig”

If you actually use that, you might get same velocity as 9×19 Parabellum using shorter barrel, which lead to doubts, if you need that backward-pull at all.

And not barrel length at that.

I.e. Theres two inchs, or an inch of rifling to make it as long as those glocks, the other inch is the chamber.

Is it? Reckon it is.

No good as a carry gun, if that kind of fault can’t be removed is it.

How are you supposed to clear it; take ages, compartively.

Hence the slow sales, probably; as it was marketed, as a carry gun. Your paying more for other benefits; assuming it works, at the time.

I have several of the XR9S and XR9L Boberg pistols. Four of them that I shoot and the rest are unfired. They are cool, everybody that sees the XR9S wants to try it. I don’t have the XR45S yet but looking. I have not experienced the bullet pulling out of the case yet and I have shot these quite a bit with several brands and bullet weights that are not on the ‘tested and approved’ list. Sometimes the rumors are much worse than the reality, in fact most of the time. I still don’t carry one, just because that is one potential failure mode that I can eliminate completely by using something else.

Cool video and interesting pistol, but odd to single it out as a “bullpup”. The 1911, Glock, SIG, and most modern semiauto pistols [but not Mauser C96, Bergmann, pistol ARs or AKs, etc.] are bullpups (magazine behind the trigger). Moving the breechface back another inch or so doesn’t change anything in that regard.

The idea is that the feed step in most pistols shoves fresh cartridges forward and into the chamber. Said step does not usually require yanking them rearward and then shoving forward. I do not even refer to spent cases in the description.

That part of the video is crystal clear, but “yanking them rearward and then shoving forward” is not the definition of a bullpup, nor connected to it in any way.

Isn’t this similar to the Gabbett-Fairfax Mars in concept?

Opps. Ignore my comment. You mentioned that later in the video.

Somehow this “game-ender of a design flaw” regarding the ammunition feeding is a complete non-issue for the litany of pull-out belt fed weapon systems out there that are held up as paragons of reliability. People just have the expectation that pistol ammo should not be crimped, and from there the problem stems. Plenty of crimped options out there, and the company took it upon itself to test & publish a list of these many options out there so users wouldn’t have to think at all, and in response the users saw it as an admission of unreliability.

The gun market is stupid and hates innovation, that’s all there is to it. I still say Arne should have stuck it out a wee bit longer & completed the 5.7×25 he was supposedly working on; the bullets are light so pull-out would not be a concern, and the round is so small that you’d be able to get probably a dozen rounds in a mouse-gun size package, and the extra barrel length would allow one to squeeze out the utmost from the cartridge. 7.62×25 would also have been a nasty little pistol, loaded with some cheap hollow points. There’s quite a bit of frustrated demand for new options in both those chamberings.

“complete non-issue for the litany of pull-out belt fed weapon systems out there that are held up as paragons of reliability”

It would be surprising, if belt-fed would not be working reliable, after over century and quarter of development of machine gun itself and ammunition for them.

If any lesson is to be learn from XR9S is that ammunition and weapon are tightly connected and both are equally important.

And that in the civilian firearms market, there is no toleration for the ammunition and weapon to be tightly connected, even if it is to reap a significant advantage. Like I said, it’s stupid & hates innovation.