Today’s guest author is none other than Julian Hatcher – although he didn’t give me permission to use his article on account of having passed away 20 years before I was born. I was looking through some old copies of Arms and the Man (the NRA’s magazine – thanks to Google’s work to digitize everything ever printed) from 1922, and found this pretty interesting article. It was written in 1922, while the US was in the midst of its search for a semiauto service rifle. Hatcher describes the pros and cons of the different operating mechanisms as they were understood at that time – including the primer-actuated Garand model that was in development.

For those who don’t know his reputation, Julian Hatcher (who retired as a Major General and went on to be the Technical Editor for American Rifleman magazine) served as Chief of the Small Arms Division in the Ordnance Department and wrote several books of great interest to readers still today, including Hatcher’s Notebook and the Book of the Garand

. He was the officer dispatched from Washington in 1916 to determine the cause of the infamous problems with the Benet-Mercie machine gun in Mexico, and he set up the first machine gun training school for the US military. Few US military officers are of more interest to gun enthusiasts than Hatcher.

With that in mind, let us proceed to let Hatcher tell us about the state of semiauto rifle development in 1922…

Note: With the exception of the first image of Capt. James Hatcher, all the pictures included in the original article were far too dark to be useful. I have replaced them with photos of the same guns from the Springfield Armory National Historic Site archives.

Recent Developments in Auto-Loaders

by Major Julian S. Hatcher

In spite of the excellent performance of the Springfield Rifle in establishing new records at the recent National Matches, the history of firearms plainly indicates that this arm which we now think so perfect must in a few years bow to the march of progress and be superceded by a weapon of even greater effectiveness. Many military experts believe that the next advance will be the adoption of a semiautomatic, or self-loading, shoulder rifle. The advocates of this view state in support of it that in the past few years several successful semiautomatic hunting rifles have been produced; that self-loading shotguns have become popular; that the revolver has gradually given way to the automatic pistol; and finally, that, after exhaustive tests and mature consideration, the Government has adopted the automatic as the service sidearm and confirmed its choice by the test of battle.

The critics of the self-loading rifle state that with our present Springfields we can get enough rapidity of fire to heat up the gun and to quickly use up the ammunition, and that greater rapidity is unnecessary. In reply, the advocates of the semiautomatic say that battle accuracy, and not rapidity of fire, is the main advantage of the proposed weapon. The big difference between the bolt action gun and the self-loader is that when you fire the bolt gun you must then lift up the handle, draw back the bolt, push the bolt forward, and turn down the handle, before the arm is again ready to fire; while with the selfloader all you have to do after firing one shot is to pull the trigger to fire again, as the arm has reloaded itself in the meantime. To visualize the advantages of such a weapon, suppose yourself in a war, occupying an advanced post. Over the top of the enemy’s trenches, 400 yards away, a gray helmet is dimly visible. You take careful aim, and then fire. To your disgust the shot strikes low. Hoping that your intended victim has not noticed your attentions, you quickly pump the bolt of your Springfield, thinking to get in another shot. Of course if you are one of the fortunate few who have benefited by Camp Perry’s grind of rapid fire, you will perform this operation smoothly and quickly, but if you are of the mass of untrained citizens who make up the bulk of our national defense, you will yank wildly at the bolt of your rifle, at the same time taking your eye from your objective and making a movement that may well betray your presence. Then you look back for your target. He has seen your motion and has gone; or, perhaps, he quickly makes you his target. With a self-loading rifle this is quite a different story. You aim at the enemy and fire; the shot strikes low; without taking your eye from your sights, or your sights from your target, you alter your aim and again press the trigger, with every probability of success.

That our own high officials attach great importance to the future of such a weapon is shown by the fact that the War Department has officially invited the inventors of the country to submit guns of this type. The Government circular states in part: “The rifle must be of a self-loading type, adapted to function with cartridges not less than .25 caliber or greater than .30 caliber, of good military characteristics, and preferably to fire the U.S. cartridge, caliber .30, model 1906. It must be simple and rugged in construction, and easy of manufacture. It should require but little more attention than the regular service rifle when placed in the hands of the average soldier.”

A test of rifles submitted in response to the circular has just been completed by a board of officers which met at Springfield Armory on November 28th. For many years the attempt to design a self-loading military rifle has received a large amount of attention from European gun designers. Both Mauser and Von Mannlicher worked for years on this problem. Many experimental models were produced and tested, but most of them were either too heavy and clumsy, or too delicate and complicated. In the earlier models, the power to operate the bolt action was obtained either by allowing the barrel to recoil relative to the rest of the mechanism, or by drilling a hole in the barrel and allowing part of the powder gas from each shot to escape through this hole and act on a piston, which in turn operates the gun. Both of these systems have the disadvantage of adding parts which increase the weight of the already heavy military rifle. In order to bring the weight back to normal, many designers reduce the barrel to a very small size, which is a serious mistake, because a small barrel is not only inaccurate on account of excessive vibration, but is also extremely susceptible to overheating, a fault which the self-loading rifle, with its high rate of fire, should especially guard against. A further disadvantage of the recoiling barrel system is the danger of getting a construction in which the motion of the barrel will interfere with the accuracy, while against the gas operated system we must record the difficulty of cleaning the gas cylinder and the gas port in the barrel.

However, in spite of these troubles, there are several guns of both types in successful use at the present time. Prominent among the representatives of the recoil operated group is the Remington auto-loading rifle (ed: the Remington Model 8). This gun, which was invented by John Browning, has been popular for over a decade. In spite of the recoiling barrel, the construction is such as to give excellent accuracy. However, the weight of the barrel is not great enough to allow sustained fire without heating. This does not impair its usefulness as a hunting rifle, but would cause trouble in military service. The Remington and Winchester shotguns (ed: Remington Auto-5 and Winchester Model 1911) are also examples of highly successful recoil operated guns.

The Mondragon rifle, of which a limited number were used by the Germans in the late war, and the French St. Etienne model, are examples of gas operated guns which have at least passed the experimental stage far enough to have been used to a certain extent in warfare.

Another system of operating automatic guns which has the merit of simplicity, is the blow-back, or inertia system, in which a heavy breech-block is used, which is not locked against the explosion at all, but is merely held in place by a spring. When the gun is fired, the bullet starts forward and the breech-block starts backward at the same time, but as the breech-block weighs so much more than the bullet, it moves correspondingly slower, and gives the bullet time to be out of the gun before the breech opens. Most automatic pistols are built on this system, as well as the .22 caliber automatic rifles. The trouble is, that with high powered cartridges the breech-block must be very heavy to make the gun safe and to prevent ruptured cartridges. With the .30 caliber Government cartridge, the breechblock of about 25 pounds weight is necessary. The Winchester self-loading rifles (ed: Winchester 1905, 1907, and 1910) are of this type. The weight which adds the necessary inertia to the breechblock is carried in the forearm of the gun. The cartridges for this gun are of a special type with a straight case and a quick burning powder.

From the foregoing remarks the reader will not be surprised to learn that the recent developments in the field of automatic weapons have been towards the production of new methods of obtaining power which will not involve the difficulties mentioned above. Only one of the rifles just tested followed the previously accepted principles of operation. This was the Berthier rifle, submitted by the U.S. Machine Gun Co. This gun is a very clever gas-operated weapon following the principles of the Berthier Machine Rifle, which passed a successful test at Springfield in 1917. This gun went through both this year’s test and the test of 1920, and appears to function well. Its main disadvantage seems to be its rather awkward shape.

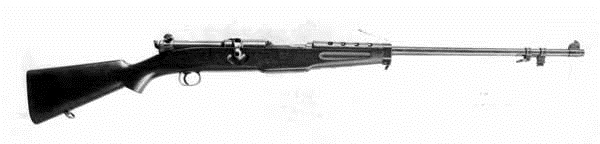

One of the guns which was tested last year (and which was being rebuilt at Springfield Armory for tests this year, but was not completed in time), obtains its power from a small cap over the muzzle. The cap slides on the barrel, and has a hole in its front end large enough for the bullet to go through. When the gun is fired the bullet passes out through the hole and the gases which follow draw the cap forward a short distance. This motion of the cap is transmitted through a rod to a lever which throws back the breechbolt, ejecting the empty shell. A spring returns the breechbolt and cap, at the same time reloading the gun. This is called the Bang system of operation. It was patented many years ago by Maxim, and was used by Soren H. Bang as the operating principle of a rifle which he submitted to our Government in 1911. The Bang gun showed great reliability, and passed the most creditable test of any automatic arm submitted before the war. However, it was clumsy and difficult to make, and the barrel had to be extremely small to keep the weight down. These disadvantages prevented its adoption, but nevertheless its excellent functioning through the various tests earned a high degree of admiration for the gun and its inventor. The system is extremely flexible, and will shoot high pressure or low pressure cartridges equally well in the same gun. The muzzle cap reduces the recoil about 20 per cent, and cuts down the flash. It is also said to reduce to some extent the sharpness of the report. Against these good points must be set down the fact that it adds a few ounces to the weight, and makes the attachment of a bayonet difficult.

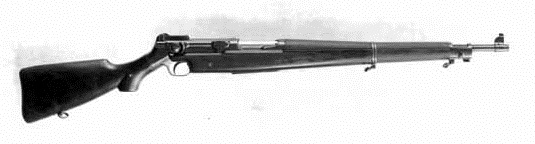

Last year Springfield Armory redesigned the Bang gun, and entered the new model in the test. The modified gun was simple, light, compact, and of pleasing outlines. It functioned well, and showed promise of success, but broke during the endurance test and was withdrawn. The board recommended that the rifle be redesigned for the purpose of perfecting it and accordingly an improved model was started but was not completed in time for the test, though work is being continued on it.

Besides the modified Bang, the Ordnance Department submitted to last year’s test a second type of rifle which was built by Mr. John C. Garand, a mechanical engineer employed by Springfield Armory. This gun is operated on a novel principle originated by Mr. Garand, which has none of the disadvantages of the systems heretofore mentioned. Mr. Garand’s principle of operation consists in allowing the primer of the cartridge to push back the firing pin, and in making this backward motion of the firing pin unlock and open the breechblock. At first this may seem a difficult thing to do, but when it is remembered that with the service pressure the total backward force on the primer is over 1,800 pounds, it will be seen that by making a heavy firing-pin, which just fits the head of the primer, a very short backward motion of the primer of not over 2 or 3 one-hundredths of an inch will put a large amount of kinetic energy into the heavy firing pin, which is sufficient to operate the gun. During the test of 1920, 3,000 rounds were fired by this gun before the board, which demonstrates without question the possibility of operating a gun on this principle. However, the test developed some structural weaknesses in the design, and this gun was also redesigned. This year’s model, which is shown in the cut, is far simpler than the one submitted last year. However, this year’s Garand gun, like the Modified Bang, was not completed in time for the test. It was first assembled and fired during the week that the Board met, and as was to be expected, some adjustments were found necessary. The gun in its unfinished state was demonstrated by firing, but was not submitted to the regular test. Work on the gun is being continued. Its light weight, neat appearance, and simplicity of mechanism have elicited much favorable comment, but of course final judgment must be reserved until after the gun is proved by an official test.

Still another rifle which shows a radical departure from the old accepted lines is the Thompson auto rifle, which was entered by the Colt’s Patent Firearms Co., both in this year’s test and in the test of 1920. This gun employs for its operation the Blish principle of adhesion, which was discovered and patented by Commander Blish of the U.S. Navy. This principle was first observed in working with large guns. The breechblocks of these guns are held in place by an interrupted screw. It was observed that in firing very light charges the breechblocks had a tendency to unscrew from the pressure on the front, while in firing heavy charges this tendency was absent, instead of being greater, as we would naturally expect. Commander Blish undertook experiments to determine the cause of this peculiarity and came to the conclusion that while the inclined surfaces would slide under moderate pressures, they would adhere and remain immovable when the pressure on them is high. Further research developed the fact that by selecting the proper angle for the pitch of the thread, a breechbolt of the interrupted screw type could be built for the Springfield Rifle that would hold fast under high pressures and fly open under lower ones. While the bullet is in the rifle, the pressure is high enough to lock the rifle shut, but when the bullet has left and the pressure has dropped the right amount, the mechanism opens and throws out the empty shell. This is the principle of the Thompson auto rifle designed by Gen. John T. Thompson, retired, the father of the present Springfield. It goes without saying that a mechanism of this kind is free from the disadvantages mentioned as applying to the gas and recoil operated types. It remains for the board to answer the question as to whether or not a satisfactory gun is in sight as a result of the test.

That Thomson auto rifle sounds interesting. Nothing as exciting as a rifle whose locking mechanism can be defeated by a misapplied drop of oil (or assembling it with greasy fingers). You should really try to find one to test Ian.

If I remember correctly it also had a problem with ejecting the casings fast enough that they could stab neck first into a piece of wood and stay there.

I dont see how thta could be anything other than myth as violent ejecting guns tear up modern brass cased ammunition to the point where its in two sepate peices only on of which leaves the gun properly. I can not imagine the brass aloys have gotten weaker over time so that sound quite far fetched

I’ve heard that the Blish lock was eventually determined to be ineffective. Its my understanding that the brass locking piece was even dropped from later Thompson models, instead relying fully on unlocked blowback operation.

Anyone have additional info on the efficacy of the Blish lock?

The Blish lock was dropped on the M1 and M1A1. It was always of dubious value in smallarms.

Was it the Remington Auto-5 or the Remington Model 11, which was the near twin of the Browning Auto-5? The Remington 11’s saw a lot of use WWII in training air craft gunners. Remington did make some Auto-5’s for Browning, but that was during WWII when Belgium was taken over. Inherited a model 11 a while back, fascinating gun, it must have been a manufacturing nightmare for all of the machining done inside the receiver. Short of using a transfer machine, the poor thing must have been passed through a dozen mills and drills to get the inside right.

On the Remington 8, wonder if the outer sleeve had been perforated, and the backwards action of the barrel exploited to pull in cool air, it that could have resolved some of the heating issues. Texas Rangers put them to good use on Bonny and Clyde.

The only difference beteen the Remington Model 11 and the FN-Browning Auto-5 was a magazine cutoff on the FN. Otherwise, they were the same thing.

no they are not dissasembly procedure on the Remington 1911 is completely different

Besides the lack of a cut-off, the Remington also has a recoil buffer pad in the receiver. Nice in concept, but a real pain to replace. The screw slots are also wider on the Remingtons. It seems like the ejector is different also, which limits barrel interchangeability if I remember correctly. And the Remington replaced one or two screws with pins. I suppose the point was that Remington didn’t use the same blue prints as FN, they made changes and technically they aren’t the same gun.

Ithica made a clone as well, which was also used by the Army Air Corp to train gunners. Grew up near an abandoned WWII bomber training base. Nearly all the buildings are long gone, but the old skeet range is still black from all the shot. How shooting down clay pigeons translated into shooting down enemy fighters would be an interesting topic.

They used it as a tool to teach gunners how to lead a target. Eventually they would put students on a moving trailer, and shoot while moving. Basically it was just a learning experiment to show why you both lead a target, and since your plane and the enemy plane would both be moving, how to lead a target while also moving yourself.

The Franchi 48 is another branch on that long recoil family tree started by Browning, and it’s still being made:

http://www.franchiusa.com/franchi-48al-shotgun/

facinating, reminds me of the firearms related writing in A Rifleman went to war.

Before I get into serious reading….. the man Hatchet was a genius a thus he is widely respected to this day. His position on semis might have been in favour of them, but if we look at development of shoulder fired arms we can see that the semi-automatics were just a step towards (mostly non-essential) full autos. Therefore, once step was done, it could not be reversed. And that is a serious problem today; select fire rifles did not increase effectiveness or hit probability but they only contributed to logistics problems. Actually, one can successfully argue that start of arms past manual repeaters led to huge ammo waste thru undisciplined fire. In my own opinion, the zenith was achieved in form of straight pull rifles such as Karabiner K31. They were fast and accurate in that combination like nothing since after.

And who has still some doubts let them check on Dallas’ shooter ‘miraculous’ score – 3 aimed shots in 7.5 seconds! And that record stands to this day, by official decree.

um, huh thats nice I think you would have done well during WW1

So did my both grandfathers and luckily survived. They carried M95 straight pull.

The K31, of which I have shot a number over time, requires a hefty pull to open. I am not sure that, in the hands of the average soldier, there is a significant difference compared to a conventional turnbolt design. I dare to say, Austrian straight pulls are not much different.

While being at it, I also do not share the British mantra of cocking on the closing stroke as doing wonders to speed. (Keep in mind: I am talking of the ordinary soldier.)

In my view, most of us, like me for example, like your grandfather, did learn shooting on a given type of weapon and tend to look upon it more favorably than on other types.

It is always that way; those who were trained and were fending for their life with particular weapon would not let it to be downrated in any way no matter how much its operation is illogical in some ways (as you refer for Enfield’s mode of cocking, for example). For most of us, as I presume, who were not in this category can have more free opinion.

When comes to straight pull I believe there are differences. Tor instance, Mannlicher as much as Ross have bolt working inside of sleeve (which provides for linear movement). K31 does not have it; it has external slider activating bolt thru pawl. Actually, I see it as a matter of progress – design evolution if you will. But I did not have the practical opportunity such as you did, so my view is based on speculation and I cannot tell for sure. A consent seen to exist that straight pull do afford higher rate of fire.

Apart from some obvious external differences ( shortened fore-end, differently-shaped upper receiver, etc. ), what significant differences were there between the original Bang Model B.1 and James Hatcher’s modified version? I ‘ve also noticed that the general outline of the B.1 more closely resembles that of the M1 Garand ( which, by most accounts, was a direct development of the B.1 incorporating additional concepts and improvements by John Garand ) than does that of the Hatcher gun.

Denmark, was the first to adopt a semiautorifle. In 1896, the Madswn, was adopted for usw on the seaforts. it was in competition, with the Qist and the Sandborg. The Bang, was mutch later. Imperial Russia adopted the Madsen in 1893, in small quanteties. The danish royal famely, had shares in the Madsen Company, andwere in close famely, with the Zar. Never the less. The US, waswery late in the semiauto bussines.

Remington made the first 1000 auto 5 in 1905. Browning, had tryed to sell the construktionto Remington before he went to Belgum, but the death of direktor Hartly , made him cross the Atlantic

As I did eventually more reading thru sumptuous material provided by courtesy of FW I arrived to A6 Meunier: https://www.forgottenweapons.com/early-semiauto-rifles/french-a6-meunier-m1916/

As otherwise being fan of Mannlicher designs I appreciate mechanically clean conception of this particular design and I must say I like it. Its pity they were not successful with it.