In addition to his work on designing a basic infantry shoulder rifle, Melvin Maynard Johnson and put a lot of effort into creating a light machine gun for US military forces to use. In terms of US military usage, he was actually more successful with the LMG than the rifle – the Johnson M1941 LMG was officially adopted and used by the 1st Regiment of Para-Marines and the First Special Service Force. Chasing hopes of wider adoption, Johnson continued to refine his light machine gun, and eventually finalized the M1944 variant.

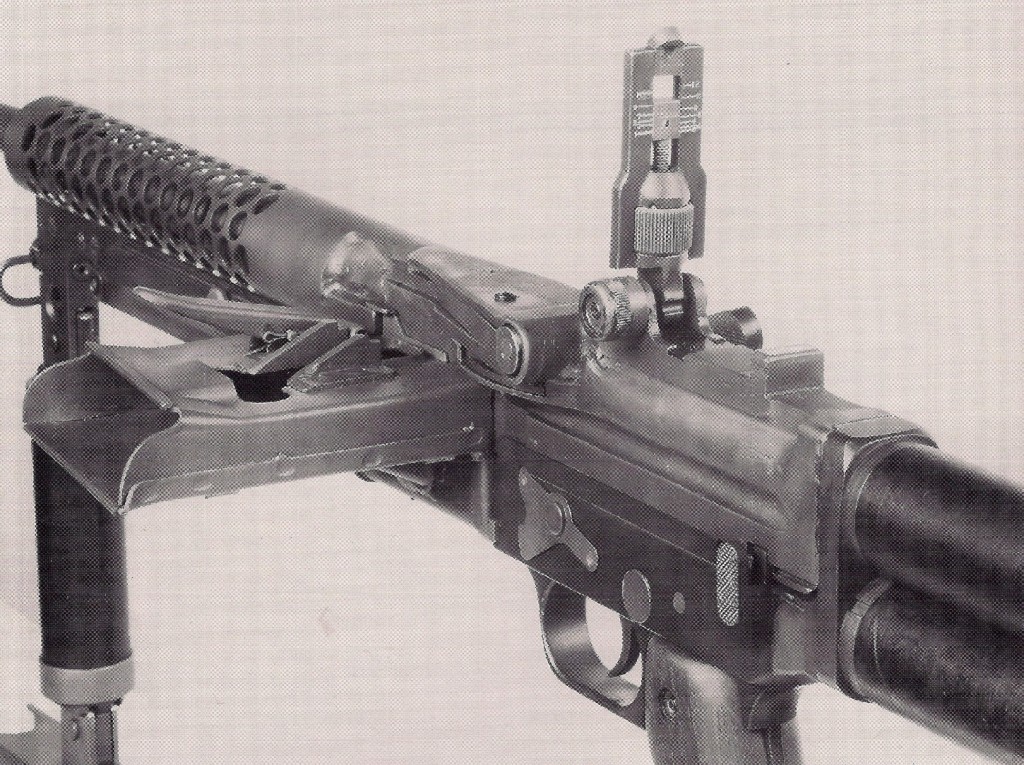

The M1944 Johnson LMG used that same basic action as the 1941 rifle and LMG, but included a number of useful improvements. The bipod on the 1941 LMG had to be removed to change the gun’s barrel, and this was a definite problem. The 1944 model fixed that, and replaced the conventional two-leg bipod with a creative folding monopod. This monopod could be used to stabilize the gun when firing prone (it’s foot had two spade-like wings to dig into the ground), and could also be folded up to use as a horizontal front grip, with the foot forming a supplemental heat shield to protect the shoot’s hand from the barrel shroud. The M1944 LMG also replaced the wood stock with a pair of tubes and a metal buttplate. The buttplate could be pivoted up to allow access to the tubes, which contained the weapon’s mainspring and a cleaning kit.

In December of 1943, ten of the M1944 light machine guns were delivered to Aberdeen Proving Grounds for formal testing. The guns exhibited problems under adverse conditions (sand, rain, mud, and cold) in those tests, but performed quite well in a following test at Quantico for the Marine Corps Equipment Board. That Board actually recommended the M1944 Johnson LMG to replace the BAR in Marine Corps service, but the recommendation was rejected by the Marine Corps Commandant, largely on the grounds that the Army had not adopted the weapon, and this would complicate logistics.

Johnson carried on improving the gun nonetheless, looking to resolve the reliability problems reported in the Aberdeen testing. His next iteration of the gun was the M1944E1, later renamed the M1945. With the design, he finally departed slightly from the original operating mechanism of the gun.

One will recall that the Johnson mechanism was a short-recoil system, with the bolt and barrel both reciprocating back into the receiver a short distance with each shot. Presumably the reliability problems discovered in adverse conditions were caused by excess friction (from mud or sand) preventing the barrel from recoiling far or fast enough. Johnson’s solution in the M1944E1 was to drill a gas port in the barrel bearing. There was no tube connected to this gas port; instead it vented against the barrel support in the receiver (8 inches forward of the chamber), and gave the barrel an additional push rearward when fired.

This gas assist provided the additional energy to cycle the gun reliably in more adverse conditions, and it also upped the cyclic rate to 600-700 rounds/minute. This extra force also required a modification of the bolt locking system in the form of an added spring and lever, to prevent bolt bounce in automatic fire.

Johnson sold ten toolroom prototypes of the M1944E1 to the US Army for $44,838 (complete with accessories and spare barrels) in late February of 1945, and one of them was put through a 20,000 round endurance trial from July 20 through August 6, 1945. The trial was not successful, and the trial was stopped after 13,190 rounds. The main problem was an excessively high rate of fire, most likely caused by an oversized gas-assist port. Thirteen parts broke during the abbreviated trial, including extractor, hammer, bolt locking cam, bolt lug cam, mainspring tube, firing pin, and cocking handle. Further trials were conducted with two of the other guns, but the Japanese surrender on September 2nd 1945 took all the urgency out of the program and testing ended in October of that year.

I have a copy of the tentative manual written for the M1944E1 / M1945 Johnson LMG, which you can download below. Unfortunately it has pretty dark illustrations and some text cut off (it’s a scan of a photocopy), but it should still be entirely readable.

References:

Canfield, Bruce. Johnson Rifles and Machine Guns. Mowbray, 2002.

Manuals

Hi! I recently bought a 1st. pattern Israeli DROR

in .303 spec. Not the most common of guns…….

Your download of the ‘Tentative Instruction Manual for

Johnson M1944EI’ will be of great value and help in

sussing-out the features common to both. Alas the

mag. is missing but as it is simply for display I’ll

adapt a Madsen mag. to look the part. I am very

grateful to you all for the service you provide.

Richie.

Hi Bruce,

I contacted you a few years ago in regard the Johnson M1941 L.M.G., I have a Field Manual on the Johnson M1944 L.M.G. which was supplied

to the French Expeditionary Forces, there are a few Johnson M1941 L.M.G. in the hands of “Bonafide Collectors” in New Zealand,

if I can be of any assistance please contact me.

Regards,

Kevin

However, tile floorings have its weaknesses, such as tendency for discoloration iif thhe

wrong mixture is employed, or chipping iin thhe event the force utilized to

clean them is simply too extreme. Keep in mind that

a deservung company won’t ever provide you with sky-high quotes.

It tells them you do not value them enough to get cleanliness.

Are there blue prints for the Johnson 1944 E1 carbine? I would like to recreate one.