John and Judy Donnelly have published a pretty cool book for those of us who like to shoot oddball guns – The Handloader’s Manual of Cartridge Conversions

John and Judy Donnelly have published a pretty cool book for those of us who like to shoot oddball guns – The Handloader’s Manual of Cartridge Conversions. It is not a reloading manual in the typical sense, but rather a reference for using commercially available (or at least less uncommon) cartridge cases to create unavailable ones. How does one make ammunition for 9mm Japanese Revolver, or 7.65mm Roth-Sauer, or 8x50R Lebel? This is the book that will tell you, with more than 500 pages of data.

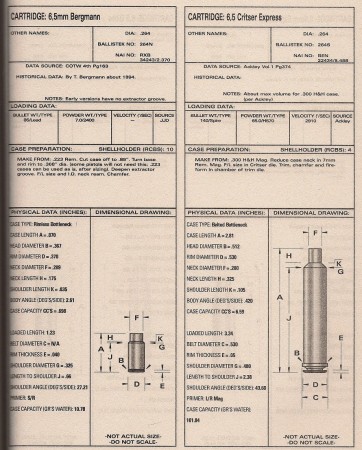

It does begin with about 70 pages of descriptive text discussing the fundamentals of cartridge case converting, and handloading in general – the tools and procedures that one will need to be familiar with to do this sort of work. But the meat of the book is in its data sections, which contain 2 cartridges per side of page. The data is spartan, but the important part is there: what case to start with, what steps are necessary to the conversion, and complete dimensions for the finished case. There may be a modicum of powder load data, but it will only be marginally useful. The history of the cartridge will be a single line at most. But that’s not the point of this book – the dimensional data and conversion processes are. You’ll still need to get reloading dies, figure out overall length, work up safe loads, and all the other steps that go into safe handloading. But this book will give you that critical first step: being able to make the brass.

I should also point out that it doesn’t address just obsolete military cartridges. In fact, the majority of the cartridges it covers are sporting rounds, from ones that are relatively simple ones like the 8mm-06 Springfield to some really obscure ones like the .33 Poacher’s Pet or the .293/230 Morris Long (and Short!). Basically, if it isn’t in this volume, you won’t find the data short of finding and asking the guy who invented the cartridge. Here’s an example page:

The limitations of the book should be made pretty clear by looking at that page. Want to know about what guns use the 6.5mm Bergmann? What type of bullet(s) it originally used? Who made it? You’re out of luck. Same goes for the sporting cartridges. You are buying this book for the dimensional and case conversion data, nothing more. Understand that, and you’ll love the book. I believe there are a few scattered typos amongst the 2000+ cartridges, but nothing systematic or serious.

The best part is that the current edition paperback is downright cheap, at $22 on Amazon. If you have a reloading bench, this volume needs to be on its bookshelf!

I’ve just checked my earlier edition (I paid £19.95 back in about 1988 or ’89 even at today’s exchange rate that’s about $30 US)

It’s certainly been well worth it for me. I found it easier to understand and more extensive than Nonte.

As far as loading data goes, I still have Powley slide rules. Geoffry Kolb, of border Barrels published a small ballistics handbook about 13 years back, explaining Powley’s simplified equations, but I haven’t got around to plugging those into a spreadsheet yet.

For all which have not Powley device I suspect this: http://kwk.us/powley.html can be useful.

WARNING

Just found some errors in my old copy of Donnelly.

These are on the small hornet and bee based ICL improved cases.

The ICL improved cases developed by the Juenkes, were at the radical end of improved, with 45 degree per side shoulders and minimal body taper.

My copy gives shoulder angle as 13 and 15 degrees. Perhaps typos mistaking 1 for 4? And 3 for 5?

It also described the improved bee as an improved hornet in the header.

Don’t know if this carries over into the current version. I’ll be writing to the Donnelly s, to make sure they are aware.

It’s well worth while getting a pencil and paper, or starting a cad package to sketch a case to scale, to see that all adds up correctly before cutting or forming metal.

In case someone wants to form the brass and reload one of these, and dies aren’t to be found on auction sites, what is the going price for custom dies these days?

My supplier back in the late 90s was Jim Goodwin (North Devon Firearm Services) I gather he’s long since retired ( http://www.rorkesdriftvc.com/discussion.php?topid=4175&forid=1 ).

If I wanted new dies now, I’d likely spend a few evenings messing about with a boring bar on the lathe

Ideally you want your brass to resize with the key headspace dimension between 3 and 6 thou (no more than 6!) shorter than what’s available on your gun

other dimensions want to be about 3 thou less than the gun has available.

I’ve read differing opinions of whether to use a higher carbon steel (1040, 1080 or drill rod) or whether to use an engineering grade 1020 mild steel (not leaded) and have the finished work carburized.

Actually, there are some dodges, like using a pistol sizing die for neck sizing, or a die for a larger caliber case of the same family for positioning the shoulder and full length sizing the case body.

I used a pistol calibre carbide die for necking down to make English rook rifle cases.

There’s no rule saying that one die has to do it all, or that a case must fit entirely into a die

But be warned about mentioning that on a reloading forum(etc). A good chance you’ll be called a liar. SB obvious how I learned that.

If that was their response, perhaps we should suggest that custom die suppliers raise their prices… now, how do I get a smiley with horns?

Keith, or anyone. What is a die, out of interest. Does it shape the brass to the correct size or?

Yes one die does that. Either the full case or just the neck.

There are also dies to seat the bullet depth and dies to crimp the neck to the bullet.

To expand a little on what Martin has said,

The brass that a cartridge case is drawn from, can be considerably re shaped.

The usual die sets are for re shaping fired brass, back to factory size for re loading. They consist of:

a “sizing” die, which squeezes a fired case back down to the size required for it to freely fit into the chamber again. In the case of ammunition for guns with either springy locking systems or weak extraction, the sizing die takes the whole case and squeezes it all down to size. In the case of bolt action rifles with front locking, you can often get away with just sizing the case neck enough to hold the bullet and as the rest of the case is not getting reworked each time, you can generally get many more firings out of the case before it wears out in one way or another. Sizing is often combined with de priming.

A seating die, which aligns the bullet with the case neck and pushes it in to the depth you require.

Possibly a crimping die to crimp the case neck onto the bullet.

For converting cases, there are sometimes multiple dies.

Although brass cases can be radically re shaped, it needs to be done in small steps to avoid the case collapsing or splitting, and sometimes it requires case necks and shoulders to be annealed to soften them again and stress relieve them before they can be reduced or stretched further.

Interestingly with the .303 British, because of the length of the rods of “cordite” propellant it was loaded with, cases had to be charged before the case was necked down to form the neck and shoulder – naturally that meant that the neck and shoulder couldn’t be heated to anneal them. The result of this was, in the tropical colonies, when the rainy season came, the case necks started to split due to stress corrosion. Stress corrosion is still commonly referred to as “season cracking”.

Often, for intermediate stages, you can use a readily available die, for example, I used a .25ACP die to shove the shoulder of a .22 hornet case back when I’m making rook rifle cartridges.

There are several other types of dies, such as trim dies, but unless you are making big cases (say .577/.450 starting from 3″ length .577 cases), it’s far cheaper to get a Lee case trimmer and use it with a power drill or, if you have a small lathe, then use the lathe for the trimming.

Well thank you both, that was most interesting.

Custom dies go for about $700 now. But, CH4D has 2,000+ calibers they consider standard. For example, they list the 6.5 Bergman and a 2 die set is $83.20.

Keep in mind that one doesn’t always need special dies for reload or for cartridge conversions. Very often one came fire form the case and then neck size with dies made for different cartridge.

That is what I did for Dutch Beumont. Someone had given me some 45/70 brass, put a small length of brass tube on it, lightly loaded them and fire formed them.

At the time Beumont dies were $600+ and basic brass to make case were $5 each. I spent less the $1.

Martin is correct. As long as the original case is smaller (shorter) than the conversion, it can be fireformed after the necking process. For example; I have a lot of .308 which I use to convert to .243 or .358. A simple conversion, true, but the basis of almost any conversion.

Now in some cases the rim may have to be thinned or reduced in diameter, but if that is the case the odds of finding an original case or dies you can afford are also thin…

Over the years that this/these books have been available, they have made it simple and affordable to manufacture, load and shoot more than twenty of the obscure and obsolete European firearms in my collection.

Make it a point to add a volume to your Christmas/birthday/wish list.

No reloader of the firearms we all love should be without a copy.

Bill.

Purchased. Thanks!

Is this a rewrite of George Nonte’s cartridge conversion book?