Bullets by the Billion is a short book (77 small pages of large print) written by one Wesley Stout and published by the Chrysler Corporation on 1946. It was a company project to commemorate the feat of ammunition production performed by Chrysler during World War II. And an impressive feat it was – between June 1942 and April 1944 the plant at Evansville Indiana manufactured (with no rejected lots) more than 3 billion .45ACP cartridges. This was done by a management and labor team with no prior ammunition manufacturing experience, and with a mid-production switch from brass to steel cases. Each cartridge involved 48 separate manufacturing operations, and was subject to 334 different types of inspection.

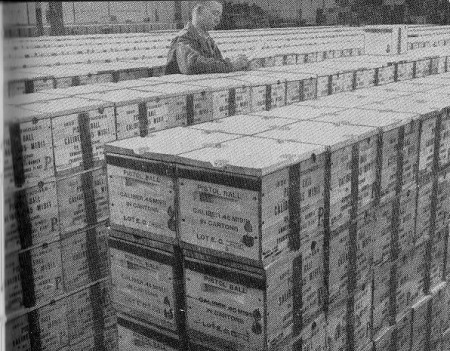

To put this in perspective, the plant ran for approximately 660 days, which equates to an average production of 5 million cartridges per day, including the time spent tooling up the factory. In addition, they plant also set up production lines to produce .30 Carbine ammunition (although “only” half a billions rounds of that were made) and to make .45 ACP tracers. At its height, daily production reached 12.5 million cartridges. What does that even look like? Well, here’s an inspector checking on part of one day’s production (at 1800 rounds per case):

The book is, of course, a bit self-congratulatory, as it was a project funded and published by Chrysler – but the pride in accomplishment is pretty well deserved. American industry was a major component in the ultimate Allied victory in WWII, and Chrysler’s Evansville plant is an excellent microcosm of that industry. A few pieces of data that stuck out:

- In total, there were more than 6 miles of conveyor belts in the factory, including a single one stretching for 2.5 miles (it carried cases out to the explosives area and back)

- Employees at the plant test-fired more than 850,000 rounds per month as part of the QC process

- When asked to tool up for .30 Carbine production, the first case was pressed within a week, and the first complete cartridge fired within two weeks

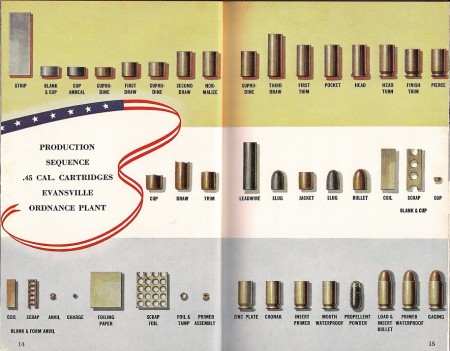

The illustrations in Bullets by the Billion are a mixture of photographs from the plant and paintings depicting Evansville products being used in combat. The plant photos will definitely be appealing to folks interested in industrial technology, as they show both the banks of machine tools for various operations and the many elements of production that were done by hand and eye. The centerpiece is also worth pointing out; a step by step illustration of the whole cartridge-making process:

The book is of course long out of print, but copies are actually inexpensive and fairly readily available on Amazon. The originals were hardcover, and it was reprinted at some point in paperback – and both versions can be had. This is not a reference book by any stretch, but it is a great firsthand account of the tireless production that stood behind US military forces in the 1940s.

If this plant was mainly just .45ACP, which weren’t exactly widely issued weapons compared to .30-06 firing guns, I can only imagine the production of .30-06 ammo.

Maybe not as many as the .30-06 weapons, but I bet there were still enough 1911s and Thompson sub-machine guns (1.5 million Tommy guns produced for WWII) to make good use of all that ammo. 🙂

OK, so maybe not ALL of the ammo as John D. points out below, but definitely in a reasonable proportion for all the .45-using weapons produced. You’re definitely right about what is surely a staggering volume of .30-06 cartridges!

Note that Chrysler Evansville was shut down in April 1944, well before the war’s end. The United States vastly overestimated the amount of ammunition needed for the war and shut down almost all ammunition production in the middle of 1944, before the Normandy invasion.

Today’s SCAMP (Small Caliber Ammunition Modernization Program) machines now fab, load, and pack more ammunition in an hour than Chrysler Evansville produced in 24 hours. Technology marches on…

The War Production Board was ramping down a lot of defense production by late 1944. They also shut down tank plants early, etc; Chrysler had let go about 1/3 of its tank production personnel by June 1945, two months before V-J day. They were producing B-29 engines right up to August 15th, though.

http://books.google.com/books?id=aQhTq18vi7AC&pg=PA138&lpg=PA138&dq=war+production+board+machine+tools+history&source=bl&ots=BadZzRY49U&sig=HLeQhqGxnMBxQFK2AyXFMa2pnlI&hl=en&sa=X&ei=uTj0Uu-6Caf52wWh2YBQ&ved=0CCkQ6AEwAjgK#v=onepage&q=war%20production%20board%20machine%20tools%20history&f=false

12 Million rounds a day sounds like a lot – but it gets even more impressive if you count it per second. That more than 140 rounds a second, or 5 cases a minute. You’d break a sweat just being the guy stacking them on the pallets.

Will there by a Bobby Dylan super-bowl Chrysler commercial to point out this production feat? Heh.

Too bad today’s 22LR production is not at this volume.

I read that actual production of .22 LR easily exceeds this number today?

Probably many more .45 ACP rounds fired in anger came from submachineguns than pistols. An amazing feat of production. Makes me even prouder that I spent a portion of my childhood in Evansville.

Amazing figures and an industrial feat! Thanks for posting this, Ian. I will try to locate a copy.

I have a similar book put out post-war by Mohawk Carpet Mills, depicting their war production of blankets and canvas. It is called Smoke:The Story of a Fight, written by their CEO reginald Harris. These reflective pieces were probably common after the war so a company could tell the world about their contribution when presumably they were embargoed during the war.

http://news.google.com/newspapers?nid=1957&dat=20020216&id=63IhAAAAIBAJ&sjid=r4gFAAAAIBAJ&pg=1928,3964518

A chance to remind their surviving former customers whom they’d had to leave un served for so long, that they were still there.

Here is the book Smoke:Story of a Fight. It is a 14.9mB pdf:

http://www.mediafire.com/view/1379z6h4363qs5q/Smoke_StoryofaFight_1947.pdf

Probably the most impressive part of all this was the mass-production of ammunition with solid, consistent quality ( no failed lots, as mentioned in Ian M’s article ) by a production team that had to translate and transfigure its previous — and unrelated — industrial production experience in a very short amount of time, and under enormous pressure due to the exigencies of war, into an entirely different arena, and without the modern-day advantages of machinery and systems such as SCAMP ( as mentioned by John D. ).

As has been said, “Lest we forget…..”.

Speaking of, I’ve always wondered what happened to the companies that failed and/or couldn’t deliver the goods. We never hear about them, but given the size of the whole endeavour it must have happened many times.

That’s where you get the rare limited production guns. Think Singer 1911s and Irwin-Pedersen M1 Carbines.

Apparently on chart shown, starting material for the case is steel, that is then plated with copper film (cuprodine)…

What I often said, ww2 proved that the victory is probably more in the factories, than in the field.

Thiel. Normally the govt would step in, seize the Property and machinery, aand if not liquidated, would bring in another company to manage the plant.

To get the big picture, download “The Ordnance Corps: Procurement and Supply” from the US Army’s official history of WW2 https://history.army.mil/html/books/010/10-10/index.html

The Steel cases, 45 and 30 carbine were zinc plated to deter corrosion.

I actually shot a lot of it back in the 60s

beltfed/arnie