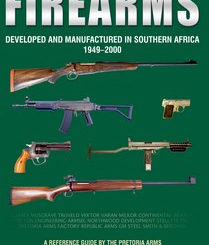

The Cobra was one of a variety of semiautomatic compact carbines designed and manufactured in Rhodesia in the latter half of the 1970s for sale as civilian self-defense weapons (primarily for rural farming families). Unlike most of these guns, the Cobra was designed as a hammer-fired, closed bolt action. It is chambered for 9x19mm Parabellum, and uses standard Uzi magazines. The action is blowback, with the hammer intended to provide additional delay to the bolt opening. In our experience with the example, however, the delay was insufficient, and empty cases showed signed of dangerously high pressure during extraction (bulges and pierced primers).

The Cobra was designed by two men, Tommy Steele and Bruce Whyte. They formed a company called Stellyte, which suffered from delays in getting production started and subsequently went bankrupt a month after the guns became available in the spring of 1977. Production was picked up by Bulawayo Armoury, and a total of about 2500 examples were ultimately produced. The vast majority have a horizontal front grip, while this very early example has a vertical front grip instead.

Many thanks to the anonymous collector who generously allowed me access to bring this one to you – and who risked his face shooting it!

Someone who knows better can/should explain but I believe that a flowed primer results from a different problem than bulged cases: flowed primer can happen even if the case never extracts at all. It is the result of high pressure and OR too much firing pin or too large firing pin hole.

As the honorable Cherndog might say: Did I mess up?

No. Primer flow-out is indeed caused by either of the factors you mentioned. Another possibility is too much linear “play” in the firing pin’s movement,allowing the firing pin to “set back” too far under firing pressure; this also may allow the primer to flow into the firing pin opening.

cheers

eon

There is a chance that flowed primers, bulging cases and going full auto are related. Over pressure sets the firing pin back. It bears against the hammer with better leverage than normal, negating some of the hammer delay. The bolt then opens too early and the cases bulge. The reduced delay increases bolt velocity and jars the disconnecter off its catch and the thing runs away. Just a theory.

Not a bad one ! Tend to agree maybe

Over pressure itself could overcome the hammer delay. I have lots of questions about what is going on.

Bore obstruction is the stock answer to over pressure. Given the difficult circumstances in which this was produced are the barrel dimensions correct? More specifically does the bullet shape eliminate the gap before the bullet engages the rifling?

Does the firing pin setback before the bolt moves?

Clearly the case moves back before obturation. Is the extractor mark on the case normal? Is the bolt too light to worry about the case head separation?

What about battering? Are there wear marks on the disconnector?

And on and on. Great video, but you can only glean so much information from it.

One more thing. The bottom rear of the bolt seems too rounded for the best hammer delay results.

Question is: what was most widely available loading of 9×19 Parabellum cartridge in 1960s Rhodesia?

Truncated cones caused the brass damage and it ran away with ball ammo, at least that is what I took from the video. IMHO the severe primer damage happens early in the cycle, but it could come from too long of a barrel as discussed elsewhere in this thread. My reading of what I see is that it is inconclusive.

Interesting. Those and the LDP/Sanna and R76/77 were all sold in small numbers, and cheaply, in the U.K. in the late 70s//early 80s when still legal. Probably few were sold and ended up being deactivated.

Pity it worked about as well as my experiences with the Walther PPS…

Personally, as an “urban homesteader” in a tiny house in a relatively low-threat environment, an M1 carbine or a Beretta Cx4 9mm is just enough rifle for me. I should be just fine with a Browning-Ingliss 9mm with shoulder stock or one of those odd Apartheid-era samopal vzor 23s or 25s turned into semi-auto-only, albeit I’d prefer the wood-chips-and-commie-plastic full stocked version rather than the folder.

“samopal vzor 23s or 25s”

Again: it is Samopal vzor 48 as it denote year 1948, or in short Samopal vz. 48

Apologies. I meant the sa24 or sa26 (vz.48a/52 and vz.48b/52 if you wish), since those 7.62x25mm weapons were those captured by SADF during the wars in the frontline states/ aka. “Border Wars” and then re-released to Boer farmers as semi-auto-only carbines/pistols.

Stock detent is shitty (sheety?) in long run, seen pics on net of deactivated ones with it bended – sheet (or shit?) steel is too light and ofc not hardened.

I think the main problem is in upper receiver small dimensions, that yields bolt that is more suited for .380 or makarov, than 9mm para, lookup Uzi and how wide receiver is it. Or they could extend bolt few inches to the front, but who would machine it all? Way too much circular machine marks for an eye to handle, rotfl.

Also, this long barrel is very much part of the problem – if you have pressure issues, you want the bullet asap out of the barrel !

Maybe in this “Scorpion” (so innovative name!, though ironically this contraption is way more comparable to dung eating “scarab scorpion” that Ian tested some years ago, than czechoslovakian legendary one) the cases end up less bulgy.

I don’t believe in blowback smg “api” theories, but here open bolt would not hurt its chances of taming the extracting case with light bolt.

Also, for the 3rd time, begging Ian for always putting blowbacks bolts on scale, even some kitchen type will do 🙂

Looking at all these rhodesian designs, one gets the opportunistic nature of the situation; they were trying something but uncoherent and not hard enough (in 1978. and war ending soon!)

If the water was really up to their necks, they would stick to the simplest possible, for example sten copy type guns, and never bother with complex closed bolt/semi only schemes.

But that would surely leave us without specialities of all these half innovative designs.

“(…)“Scorpion” (so innovative name!(…)”

Also, interesting name coincidence with SSN-589 lost to unknown cause in 1968:

https://en.wikipedia.org/wiki/SSN-589

though I do not know if that story was well known in 1970s Rhodesia

When I first saw that Cobra I have feeling that I saw something similar earlier, after some think I concluded it was Veresk sub-machine gun:

http://gunrf.ru/rg_pistol-pulemet_veresk_eng.html

which is externally somewhat similar with forward grip deployed and has top-folding stock, though internally it is much different as it is gas-operated weapon.

The SR-2 Veresk SMG’s design copies the Cobra SMG in general shape but upgrades the grip to a solid piece.

The SR-2 Veresk SMG’s design copies the Cobra SMG in general shape but upgrades the grip to a hinged design to facilitate stowage under the handguard.

I don’t think the russkie designers of Veresk were familiar with Cobra smg, they maybe didnt even heard about it.

The design, engineering, workmanship, and functionality are all quite comfortably in Chinese mystery pistol territory.

The barrel looks some over 25 santimeters and the slide weight seems roughly 200 grams. With 7 grams of 9mm Parabellum bullet and 1,1 base headsquare/ bullet base square and accepting the time unit as the time of bullet leaving out from rifled lenght section of the barrel, free blowback computes some over 8 milimeters from the breech at instant of bullet’s leaving off the gun. Too much for a closed bolt firing blowback gun. Also, hammer delay seems as though for the full backward blowback distance as seen on the given leverage ratio and not for the time for the maximum pressure within the bore existing. Over pressure indications seem normal. Seems a weak design for the barrel of this lenght.

With 200g cases would blow up, I’d say around 300 grams, but thats still at least 150 grams too low!

Even with half of the 10inch barrel would be.

Thanks for your interest. Usual acceptance for free blowback distance for closed bolt simple blowback guns is 2 milimeters and this value needs some 850 grams of slide weight for a 23 milimeters of rifled section of barrel. However, in real life practice, most of brass cases stand for higher value distances than computed without blown up. l have seen 150 grams slide weighted and 11 cm barreled auto loading hand made pistols delivering slightly bulged cases. APl Blowback is the answer for SMG sized auto guns.

“(…)too low!”

This combined with “skinny” nature (for 9×19 Parabellum cartridge) leads me to wondering if they did not originally intended it to another (weaker) cartridge? Maybe 9×17 Kurz [.380 Auto], but I don’t know if this was popular in 1960s Rhodesia?

Its pretty much a Mac 10 copy. What’s original on this thing?

Fcg is very much different from original open bolt m10, and some other stuff.

It does have some innovation credits.

Thanks a lot, Ian! This is not the last gun from Rhodesia in your channel, I hope. As for Cobra gun: blowback action and pretty rigid springs – the same way in soviet PSM pistol, and it’s works (in pistol). BTW, Tommy Steele – that’s an pseudonim, taken “in the name” of “british Elvis”, I suppose. In Rhodesia many of the immigrants from Britain and US took pseudonyms, especially mercs. Sorry for my english- me no habla, me sooo russian.

Many thanks Ian,

RHODESIAN Cobras and Ldps were bargain basement cheap shite in Britain in the early 1980s.

The chief selling point seemed to be the telescoped bolt, similar to the uzi. ..

Yeah, that desperate. For real!

The guy who leant me over $100 billion (zim) – they got out before the hundred trillion dollar note was issued…

Said that they used to carry actual uzis as the gun of choice. I’m not sure how they were sourced, but the close connection between apartheid Israel and apartheid s’ifrica and apartheid syphrica and Smithy’s UDI Rhodesia, can’t be ignored.

Ian’s comments about the run away with 5 rounds being very rapid, is no exaggeration.

What rate was it? Something like 1000/minute or more?

Typical open bolt smg rate is 550 to 600 per minute.

Bulged cases were not uncommon pickups on British ranges during the fashion for pistol calibre carbines in the early and mid 1980s.

Yeah, I think that the bolt is on the light side.

Hammer delay is marginal at the best

It relies on the inertia of the hammer in rotation

Spring strength only serves to slow the bolt down after the high pressures are over.

Spring force doesn’t delay the critical high pressure opening of the bolt at all.

One of the guns which does use the inertia of the hammer to delay unlocking, is the original Browning/Colt 1911

The 1911a1 introduced a bevel at the base of the slide to engage the hammer higher up (for less inertia)

This made manual cycling easier, but may well have materially reduced the life of the pistols.

The primer trouble looks like an over sized firing pin tip and oversized firing pin hole, giving insufficient support to the primer.

I’ll send one the request for Ian to put bolts on to kitchen scales

Also to give measurements of spring diameter, wire thickness number of coils etc

I’ll second the request to Ian to…

Damn the auto incorrect