For those of you who don’t regularly visit GunLab, Chuck posted an update there yesterday that’s worth checking out. He has spilled the beans about deciding to manufacture a small run of reproduction Gerat 06 rifles. This was an intermediate design between the Gerat 03 (basically a roller-locked G43) and the StG-45 (the first roller-delayed blowback gun, which eventually evolved into the HK91).

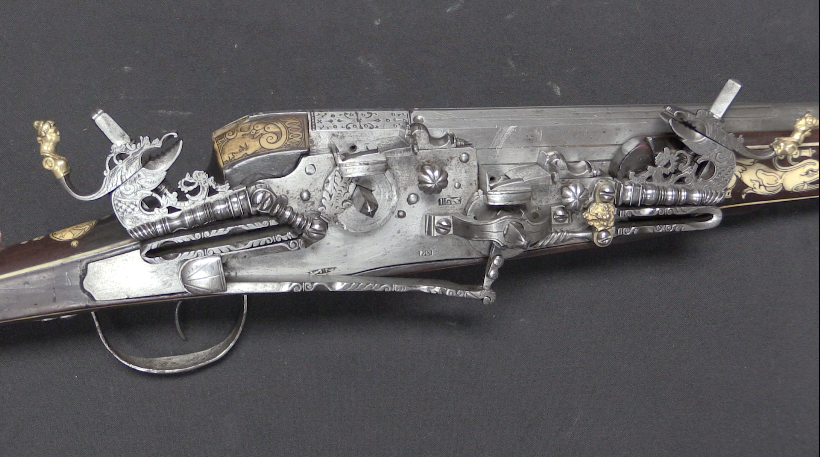

The Gerat 06 is a stamped-receiver, gas-operated, roller locked rifle in 8x33K, using standard StG-44 magazines. They are a little bit heavy (no more so than the StG-44, though) and very, very comfortable to shoot. Only 4 were originally made during WWII. I have no idea what the price will end up being, when they will be finished, or how many will be available, but I will be happy to put your name on a list if you’d like to be contacted directly when they are.

For more information on the design, you can check out the video I did a while back: Last Ditch Innovation.

Definitely the best video you have done. You did not mention, are the original guns select fire?

Yes, the originals were select-fire.

Wow, that is just awesome! Very, very cool. Thanks for the update! Kudos on the highly informative video clip too!

I need to be on that list. And the VG1-5 list, too.

Great video, showing the differences between the two versions. So you really need to hire a German pronunciation adviser ;).

Where do I have to apply for the job? 😉

O…M…G…!!!!!!!!!!

Very nice video.

It will be the Gerat 06H I presume. Why not go for the stg 45, or are there no differences between the 2?

oooh! I love all those pictures of stampings etc on that website.

Excellent presentation Volks Studio!

The former design, with its built-in delay in form of piston is in my way of understanding superior (omitting cost difference for a moment) and only makes me wonder why it was not duplicated after the war. In comparison, the “more developed” version in form of ‘half-locked’ design was proven to be rather problematic and now is relegated to FW category. All-in-all, this is an excellent demonstration what are people capable of when extreme need arises.

Something I wanted to mention and missed; actually, the roller or ball lock very similar as the one applied in these developments was in existence as means of quick tool fixing (chucking) to machine-tools spindles. It’s basically identical idea.

I think I know what you mean Denny, do you mean like a spring loaded ball bearing held inside an object that allows it to protrude from it. Then you put said object inside something else, which squashes the protruding part of the BB. And inside of the item into which the object is put into, there’s an indent which allows the BB to protrude out of the object again therefore holding the two together?

A “Snap on” tool, like a socket set.

Yep, you got it!

I think you might be right there Denny 🙂

Cool stuff – how do you subscribe to Gun Lab? maybe I missed something on their page.

Looks like you already are subscribed…

Until the other day I never knew of the Gerat 05. I still lean toward the older style of guns.

I hope you do a review on all of these guns he’s making. One of your 2 gun runs would also be nice.

How wonderful that a small handful of dedicated machinists and historical firearms mavens are keeping such a rare and forgotten weapon alive! This is a major addition to what assorted governmental departments, major military museums and other institutions, with their relatively large budgets and potential access to generous sponsorship and endowments, are able to do.

I know that I may sound overly critical in this respect, and would not be surprised to hear of many opinions to the contrary ( I will be the first to say that many, many museums and similar institutions have done an incredible job of preserving the history of firearms and weapons as well as their inextricable link to humanity’s endless travails, often in spite of budgetary and other pressures ), but what I am getting at is the regrettable tendency to overlook “obscure” ( but significant ) historic milestones such as the Gerat-06 in favor of more “obvious” weapons for the sake of a broader contextual representation to the general public.

It’s not really so much a pointed criticism on my part, as it is an observation.

That is a plausible statement you make Earl. On the other hand you may want to ask: “is this really of any true meaning, part of replaying history?” Progress has moved in different direction and these items are more-less relics.

What I am trying to say is: we have some historical examples in museums, we have pictures, drawings and patents…. should be plenty to see and to study.

Perhaps I should have read more carefully; you seem to actually say that, in your own way.

Thanks for your input, Denny. It is always good to have a discussion with differing but respectful opinions and evaluations. It is the best way for us to learn, and is most helpful for all concerned.

Earl, you know me, with my ‘far reaching’, but whole lot missing considerations.

Happy Easter to you and all FW readers (and to Editor, of course)!

Hello, Denny :

With your extensive knowledge of firearms and global history as well as your related military background, I think you are being much too modest :). I have always held great respect for your viewpoints as well as those of other knowledgeable FW contributors.

And thanks very much for the kind wishes of this season — wishing you, your family and all on FW a Happy and Meaningful Easter!

It’s good isn’t it Earl, maybe they cut make cut away versions and try to sell them to museums for use in school trips or something.

Hi, Pdb :

That’s a good idea from a historical/mechanical educational standpoint.

Chucks work is truly amazing!

I watched the authors video on the German WW1 Jager pistol once, and I was wondering if that was the first sort of notion for pressed parts i.e. Identical sized/shaped stampings which form either half of a weapons receiver/frame etc? If so was it because “presses” were a new invention made available by newer technology, I am assuming a press is a kind of stamping machine.

Interesting video. Who made the guns you used for the video. I know of a few Gerät 06H rifles built by an Englander but have not heard of any of the Gerät 06 rifles being built. By the way….you’re pronouncing Gerät wrong…pretend its spelled Geraet and say it with the long ” a ” sound.

One other comment about extraction and common myths that are way off reality. The bolt does not extract the case from the chamber and case head separations are not caused by the bolt yanking the case head off. The flutes in the chamber ease extraction in the later model o6H. They allow the whole case to float in the chamber where otherwise it would be held there by friction caused by high gas pressure forcing the case against the chamber wall. The case head area is unsupported and when pressure rises the case stretches rearward pushing the bolt back. If it stretches too far it will break. In a gas operated rifle this is controlled by the piston unlocking the bolt. By the time the bolt has been unlocked the pressure has dropped to a level that won’t split the case. In the delayed blowback action the case starts the bolt moving rearward during the high pressure phase and the bolt then continues to move back allowing the case to stretch even more until it breaks. By fluting the chamber and floating the case it allows the whole case to move rearward at this time and prevents it from breaking.

In reality very few firearms operate by the bolt yanking the case from the chamber. They operate on residual pressure forcing the case rearward against the bolt and when it unlocks it is the case that forces the bolt back not the other way around.

Timmy

In say an M14, I watched a video “Original Army educational lark” one on youtube, it seemed to imply twisting the case helped extraction. Is this a peculiarity of this particular weapon, or do most rotating bolts turn the case to aid extraction or merely as a consequence of the locking system in your opinion Timmy. I suppose what I am saying is, in a non rotating bolt system would it help to turn the case via some system. Or is pressure always less in rotating bolt systems, therefore there’s less impetus on the case to extract itself via gas because rotating bolts are slower to function for example?

In an Mg42 the rollers lock into the barrel extension while the barrel is fully forward, in a manner which allows them to protrude from it’s outer slightly. When fully forward the barrel extension sits forward of a “socket” for it attached to frame sort of thing. Then when you fire, the barrel extension comes back and enters the socket aforesaid were the protruding parts of the rollers from the extension are “squashed” by it. This then unlocks the bolt from the barrel extension, and it functions as per. Which in essence means the Mg42 opens itself, not in the same manner as the Gerat 06H well it doesn’t in the sense the “socket” isn’t part of the bolt mechanism but does given said socket isn’t a mechanical piece like a gas piston its just there as part of frame which holds the barrel surround thing to the frame.

In away the Gerat 06h is the Mg42 inside out, the Mg42 system would work in an assault rifle platform only the barrel would need to move still obviously and although it doesn’t need a separate gas system it is perhaps quite bulky due to the extension. It’s inside out, because instead of the rollers being “squashed” closed upon moving back, they are squashed open upon moving forward type thing.

I am just wondering why rollers replaced flappers in the assault rifle configuration given you can see why they would be beneficial in the Mg42, as oppose flaps given they roll closed when being squashed by the “socket” when moving backwards, were as flaps would be more likely to catch during this motion malfunction friction etc. However given the design of the Gerat 06 didn’t function in away were flaps would have been perhaps problematic as outlined above, perhaps they were thinking more Mg42 and ultimately the 06H when they made the gas tappet version otherwise why didn’t it use flappers given what advantage did rollers provide in a locked system without much movement unlike in the O6H or the Mg42.

G41/43 both used flapper locks, in fully locked systems.

The only weapon using rollers was the Mg42, which while it was locked as was the 06 the Mg42 moved more like the 06H than either the G41/43 or 06.

Mind you they designed a 03 model which was a “upgraded” to rollers G43 apparently so I presume, rollers had some advantage over flappers even in a fully locked design.

The 06H doesn’t have a hammer does it, to fire?

The 06 neither, it’s like the Fg42 in away “that way” on the 06H the bolt carriers extension rod is under spring pressure so the rod is released by a sear presumably.

On Hk models, with the “rod” above/forward, do they have hammers I’ve fired a Hk53 but never stripped it?

If my understanding of the Mg42’s function is correct, I think of the 06H like this.

The Gerat 06H’s bolt carriers extension rod, is the barrel/barrel extension on the Mg42 back to front. The bolt carrier on the 06H is the “socket” on the 42, now in reverse the “barrel” hits the socket locking the rollers, upon recoil the 06H’s carrier acts as the “socket” on the 42 ie. On the rollers i.e. The bolt, unlocking it however now the “socket” is attached to the bolt.

The 06H has a very different bolt “bar rollers” to the 06, the 06H much more resembles the Mg42.

Now, how about the G43 roller Gerat 03 was attempted without the gas tappet. The rollers replacing flappers because they wondered about recoil, the 06 was the same however they now made an arrangement more reminiscent of the 45 in regards the layout the stock etc. Couldn’t get it to work, went with the tappet on both occasions. 06H Eureka, it worked. It worked because of the layout in regards the weapon, and internals being more 42 but inside out.

Or they went with rollers, because they were less likely to be formed differently than flappers in regards the structural integrity of the pair, each needing to be identical and perhaps the wore better in regards headspace generally.

Personally I think they knew before the bounce in the 06 but I may be wrong, the actual inventor probably got hit by an Acme cartoon bomb from a Lancaster.

Anyway one thing is for certain, if “you” me, or anyone else was sitting on the board of (National Socialist, ordnance) or the Queens, or Presidents, you would have thought blimey finally here we are the masterpiece.

“Maybe this weapon can save us from being fascists, hurray! They must have said in Gerry”

Cough, anyway whatever.

First – love your website and YouTube videos! Your reproduction of the Gerat 06(H) is very impressive – please put me on the list to be informed when they become available. That would be the perfect evolutionary step between my StG44 and and my HK93.

Were you able to use any HK91 parts in the Gerat 06(H) you’ve completed? For example, the bolt looks identical in both rifles.

PDB your understanding of the 06H system is wrong. The MG42 works more or less as you understand. The rollers are forced out in to the barrel extension by the rear half of the bolt forcing a locking piece (wedge) forward to push the rollers out into the barrel extension. When the barrel and locked bolt recoil a set of cams pushes the rollers back into the bolt head and allows the bolt to continue rearward while the recuperator pushes the barrel forward.

In the 06H the rollers are forced into the barrel extension by the rear half of the bolt as the locking piece contained there wedges them out. The angle on the locking piece is such that when the round fires the bolt head is pushed rearward by the case in the chamber. The flutes in the chamber allow gas to keep the forward end of the case from sticking to the chamber walls and allows a bit more bolt thrust. The rollers are sitting on an angled surface in the barrel extension as well as against the angled surface of the locking piece. As the case pushes against the bolt head the rollers push the locking piece rearward which forces the rear half of the bolt rearward at a higher rate. There is a mechanical disadvantage here and it takes time for the carrier to start moving. This allows the pressure in the barrel to drop to safe levels. As the carrier has started moving inertia continues to keep it going to the rear. Once the locking piece clears the rollers they can be completely retracted allowing the bolt head to be pulled back by the carrier as well as being pushed by the residual pressure on the case in the chamber. There is a complex relationship between the size of the rollers, the angle of the locking piece and the angle of the barrel extension. In this system the bolt is never really completely locked and for that reason the germans called this system “Half Locked”. The Gerät 06 system was truly roller locked with a gas piston to operate the locking piece. It had more parts however and cost more money so the half lock system was better as far as they were concerned.

Hope that helps

Timmie

would love to buy just the bolt group of the gas op. ( locked) 06 – think I can take it myself from there