Today we have another guest post, and this time Leszek has really outdone himself. The subject is the Polish PM-63 machine pistol…

PM-63: Poland’s First PDW

by Leszek Erenfeicht

Almost twenty years before the West went PDW-crazy with advent of the micro-caliber rounds that made the concept viable at last, a machine pistol was created in Poland, showing all the features required from that seemingly so novel class of automatic weapons. It was officially called the Pistolet maszynowy wzór 1963 (PM-63), but most people refer to it as the ‘Rak’ (Polish for cancer). It was lightweight, compact, capable of serious firepower, yet could be holstered to leave the hands free for whatever job they were needed for. And at the time, when boxy just started to seem sexy, those classy, curving lines of the Rak pleased the eye of beholder.

The re-armament of armies with automatic rifles chambered for intermediate caliber ammunition throughout the 1950s and 1960s resulted in growing marginalization of the classic pistol-caliber submachine gun. Yet, it was this very same process of warfare modernization that brought it down to the brink of extinction, which paradoxically brought it up back again – although in a completely different guise. A new wave of compact SMGs, or even machine pistols, were meant to be the self-protection weapons for the commanders, gunners, drivers, pilots and the like. Their jobs, indispensable in the modern warfare, were much more important than wandering around in the boonies, wielding a decent rifle. More, it takes an awful load of money to train one – and so, to protect this investment, a PDW-style weapon had to be devised from the scratch. It was so, because the level of technology available in 1950s did not allowed to cut down the intermediate-round assault-rifle any smaller, and the classical SMG was too large and bulky to fill the billet: something completely new was needed, and quick.

There was one additional problem to the East of the Iron Curtain: the wartime experience had proved beyond reasonable doubt that the 7.62 x25 Tokarev round is too powerful to have a controllable compact SMG chambered for it. At the same time, despite the awesome energetic level and penetration of this round, it was less-than-stellar terminal ballistics-wise. It was even worse in it’s handgun ammunition role. The Soviet Army, having been just re-armed with it from an obsolete, 19th Century, but virtually recoilless, revolver (the M1895 Nagant) loathed the large, heavy and kicking like a mule, yet inefficient Tokarev M1933 pistol. In 1951 the Soviet military went to another extreme, adopting instead a small-sized, blowback Makarov pistol instead. It was chambered for a new round, the 9×18 ‘57-M-181S’, designed by Boris V. Syemin, but referred to colloquially as the ‘Makarov round’ from the gun that chambered it. This was reasonably accurate, and reasonably efficient at pistol distances, but way too weak to have any effect at the classical ‘front-line’ SMG fire exchange distances. On the other hand, it’s small size and limited level of energy allowed for creation of the compact machine pistols, like the Stechkin APS. In the field, though, where obsolete tactical doctrine called for it to perform a surrealistic role of the soldier’s primary combat weapon, it was soon deemed inefficient and replaced with a folding stock AKS automatic rifle.

One of the facets of the post-Stalinist ‘thaw’ in the Eastern Bloc was the drive towards legalization and petrification of the satellite-states dependency on the USSR, in the military terms taking shape of an alliance to counter-weigh the NATO. The treaty was signed in Warsaw, Poland in May 1955, and therefore it was called the Warsaw Pact – even though it was steered solely from Moscow and served solely Moscow’s interests. De facto it changed the situation marginally – it was still the Soviet Union that commanded the ‘allied’ military forces directly from Moscow, but in theory they were now independent national military forces – if only on paper. The Treaty allowed for a re-creation of the national façade in each member-state’s military, and loosened the up to then iron grip the Soviet Union hitherto exerted over their defense industries and armaments. At the same time the ‘allied’ armies were shown the hitherto top secret Kalashnikov rifle and Makarov pistol with their respective ammunition, whose appearance was met with amazement. So much money was spent by the Czechoslovaks on their intermediate round, while the Big Brother already had such ammunition for several years! So much money was wasted to buy licenses to manufacture the ‘world’s most advanced’ models like the M44 Mosin carbine, the PPSh41 and PPS43 submachine guns or the TT33 pistol, while the seller knew perfectly well that they were obsolete and even worse – that immediately after the new rounds and arms are de-classified, the ‘allies’ would have to pay even more for another set of licenses!

The growing concern over these practices made the new post-20th Party Congress Soviet leadership take an unprecedented step. As the military establishment was adamant that the 7.62x39mm chambered rifle have to be the backbone of each ‘member-state’ army, the manufacturing licenses for SKS and AK were for a limited time offered at very reasonable discount prices, while in the handguns department everyone was left to his own devices altogether – provided they were chambered for the 9x18mm. This was a remarkable step aside from the Stalinist-era extortion-style marketing, so most Warsaw Pact states jumped upon the occasion. Only the neo-Stalinist Czechoslovak leaders of the era chose to literally ‘stick to their guns’ – and became the only Warsaw Pact state to have their army completely kitted-out with domestic hardware.

Wilniewczyc Redux

Piotr Wilniewczyc, the inventor of the most famous Polish small arm, the Vis wz.35 (a.k.a. the Radom) pistol and the co-creator of the deservedly forgotten Mors wz.39 SMG survived the war, and after the cessation of hostilities returned to work. His weapons designing abilities were not needed, though – the official position of the new rulers was that designing indigenous guns is pointless, as the superiority of the Soviet small arms design is prevalent. He started to teach mechanics again, at first in the Lodz Technical University, as the Warsaw’s one laid in ruins. He then returned to the capital, and while teaching the young engineers, he wrote several books, that for years were the backbone of small arms designers education in Poland.

After 1955 the Polish small arms design school was revived – as fortunately many of the pre-war foremost designers survived both WW2 and the subsequent civil war and political purges. In 1957 Wilniewczyc started the design of his first post-war semi-automatic pistol, the WiR wz.57, chambered for the 9×18 round. His design eventually lost to the competitors, the group of young military small arms experts, who designed what later became the P-64 Army pistol.

While still honing his WiR wz.57 design, Mr Wilniewczyc started to think about the compact, light automatic weapon for close-combat role, chambered for the pistol round – something along the same lines as the APS Stechkin, but from the first instant intended to be a purely self-defensive weapon, and not a primary armament. It was meant for platoon leaders, support weapon crews, airborne troops and the Ministry of Interior special security services. In late 1956 and early 1957 he had already created a study of such weapon, with the grip-mounted magazine well and slide telescoping over the barrel, something of a cross between a classic SMG and a semiautomatic pistol. It was an incarnation of the ideas developed by his former subordinate from the pre-war times, Jerzy Podsendkowski, in his 1944 MCEM-2 weapon, designed in Great Britain. The MCEM-2 was an ancestor to the whole generation of the post-WW2 submachine guns with grip-contained magazines and breech-bolts telescoping the barrels – the Czech Holeczek SMGs (Sa-23/25 chambered for the 9 mm x 19 and Sa-24/26 for 7.62 mm x 25) and Israeli Uzi being just two most famous of the lot.

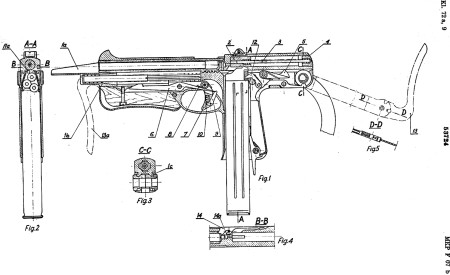

The 1957 study weapon was a blowback one, and already fitted with the rate reducer. The form of its slide proved to be one of the most outstanding (some would even say – outlandish) features of the Wilniewczyc gun. It is an outside-fitting slide, reciprocating along the rails on top of the frame, just like in an ordinary semi-automatic pistol, but contrary to the APS, also with an outside slide – this weapon fired from an open, rather than closed bolt! The barrel, fixed yet easily replaceable, was connected to the frame by five ribs – just like in John M. Browning’s FN pocket pistols.

At that time the code-name Rak was also born. Several urban legends are connected with that name, the most persistent of them making it an abbreviation from Ręczny Automat Komandosów (Commando Hand-held Automatic Weapon). The late Professor Stanisław Kochański, close associate and pupil of Mr Wilniewczyc, disputed the theory. The word “Automat” was used in Russia, at the times Mr Wilniewczyc studied small arms designing there during the WW1, and later on, up to this date (e.g. Avtomat Fiodorova, and later the Avtomat Kalashnikova, the AK), only for automatic rifle-class designs. Mr Wilniewczyc was famous for his terminological purism. He time and again have chastised his students and co-workers alike for such blunders, and so it is highly unlikely that he would ever call his work using the wrong term, as it was chambered for the pistol round. According to Kochański, the name Cancer could stem from two things. First, the cocked weapon was very unusually shaped for these days – it looked as it was positioned backwards, just like the ‘canard’ airplane flying the horizontal stabilizer first. In Polish language there is an expression ‘chodzić rakiem’, meaning ‘walking backwards’, like the cancer moves. The indirect proof that the name was used as a word – and not as an acronym – is Wilniewczyc’s own joking remark from the times, where he fought an uphill struggle against the terminal illness, that eventually killed him in December 1960. He is reputed to say then, that ‘Either the cancer is going to finish me first, or I would finish the Cancer earlier’, playing on the names of his gun and his illness.The cancer got the better of him on December 23, 1960. After his death, the Rak design team with Marian Wakalski, Grzegorz Czubak and Tadeusz Bednarski took over the whole of design and started to perfect it.

The Novel Design

What started to emerge after a year of their work, was a truly remarkable gun, with many novel and unconventional design features. The Rak was a selective fire weapon, yet the trigger had no selector lever of any kind. It fired semi-automatically when squeezed lightly, and full-automatically, if squeezed all the way back. This was pioneered as early as 1920s in the Arsenal Tallin SMG (1924), then the idea was taken over (though of fundamentally different design) in the early 1930s by the designer(s?) of the B.M.P.32 Bergmann submachine gun. The Polish design is again radically different from both Tallin, Bergmann and Czech Sa-23/26, using only the general idea of progressive trigger. Soon, in 1969 the Austrian Steyr MPi-69 joined the progressive trigger selective-fire club, but the feature still remained unique and deep-niche, until in 1977 the space-age Steyr AUG rifle made it a household idea.

The slide was still an outside-riding type, like in the Danish M/1945 Madsen. According to Kochański, Wilniewczyc deemed that a vital advantage of his design, making Rak much more difficult to jam. He compared such a slide to the Roman sandal – if a pebble enters it, all the wearer has to do, is to shake it out and walk on by. If that pebble enters the high laced boot (or the bolt buried under bolt cover, deep inside the receiver) it takes much more time and effort to get it out. He might as well be right – but on the other hand (or foot?) it is much harder for the pebble to enter the boot than the Roman sandal!

This outside slide was provided with a muzzle jump compensator – a trough-shaped projection of the slide, extending beneath the muzzle, which Polish soldiers christened the ‘spoon’. This spoon travels with the slide, which enables for another useful unique feature of the Rak – it can be cocked single-handedly, by resting the spoon against some hard object and giving the pistol grip a shove – until the slide trips the sear and remains in cocked position. After depressing the trigger, the spoon would now travel back to battery with the slide, and will be projecting under the muzzle at the moment of discharge, deflecting some of the gases upward to reduce the muzzle jump.

Also the case ejection is somewhat unusual. The extractor is placed in the bolt face of the slide, quite conventionally, but the ejector is actually a projection of the left magazine lip, as in the Webley & Scott M1909 pistol. Wilniewczyc liked that feature and to implement it, he went back to where all burp-gun designers fled from in horror – he revived the scepter of Schmeisser staggered-row, single feed magazine, seemingly buried deep once and for all after the WW2. Unfortunately, as if this was not a bad enough idea in itself, when combined with a cartridge so short and stubby as the 9×18 it proved very hard on loader’s fingers. The staggered-row, double feed Stechkin magazine is much easier to fill.

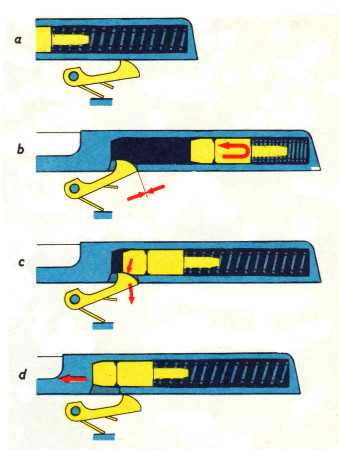

Another Rak’s gadget is an inertia in-line rate reducer. It retards the return of the slide in fully automatic fire to limit the rate of fire, which in a compact burp-guns is always a good idea. The rate reducer consists of two parts – a weight reciprocating within the rear part of the slide, and a spring-loaded lever raising from the rear part of the frame. The weight travels back with the slide. When the slide hits the rear of the frame and rapidly decelerates, the inertia of the weight overcomes the pressure of the weight spring, continuing on it’s rearward movement. As the weight slides rearwards inside the slide, it reveals a slit in the bottom of the retarder chamber. Into that slit a spring-loaded retarder lever hook engages, holding the slide open. Then the retarder weight hits the rear end of the slide and after a short while it’s the spring’s time to overcome the inertia of the weight, eventually slamming it forward inside the retarder chamber of the slide. The conical head of the weight pushes the retarder lever hook out of engagement with the slide slit – thus freeing the slide to return. If the trigger is squeezed all the way, and holds the sear depressed, the slide propelled by the return spring slams home, stripping another cartridge from the magazine lips on the way, chambering and firing it. If the trigger is squeezed just half-way through, though, the sear is released by the disconnector, catches the slide and holds it, until the trigger is released to reset the trigger mechanism.

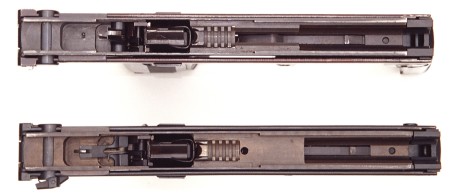

The rate reducer weight of the Wilniewczyc’s original project was truly cylindrical in shape, single-piece, and made of tungsten – a metal much heavier, but also much more expensive, than steel. This early retarder is set on a guiding rod, along which it travels, which at the same time keeps the weight’s spring. It was only known from the patent drawing, and it is not sure if it was ever made. The later reducer weight is also single-piece affair, but longer, with tapering front and rear edges, and with a rear part of somewhat smaller diameter. The guiding rod was dispensed with, the reducer weight was made solid, and the spring is much wider in diameter – the narrower rear part (stem) of the weight doubles as the spring guide. Such arrangement was retained as late as early production, and all the Polish Army FMs, early TM and weapon’s charts feature that type of reducer. But after a mere one year of production, a military review board ordered several changes, mostly to decrease the unit price of the Rak. One of these was to get rid of the tungsten weight. Instead it was made of steel, elongated to retain the weight. Shortly afterwards it was plain that the elongated one-piece reducer weight increased the wear significantly. As of early 1970s all single-piece reducers were ordered to be replaced with a new, two-piece design. This was also an all-steel one, with no tungsten, and consisted of two parts, that according to the late issue TM are called ‘retarder’ (the cylindro-conical forward part) and ‘inertia weight’ (the rear part), as if they performed some different roles. The laws of physics make them both travel together and act as a single unit – but now that they are separate, the tensions developed are smaller, and the weight broke off less frequently than the one-piece model. In it’s final design the reducer slows the rate of fire from well over 1000 rpm without it to 600-650 rpm.

One of the most characteristic gadgets of the Rak is the folding forward grip. This is a late addition, though. At first the Rak was fitted with a wooden fore end and a under-folding metal stock with a rotating, U-shaped, arched butt-plate, somewhat reminiscent of the AKS, but narrower. The weapon could be shot with stock in one of the three positions:

- Folded with the butt-plate folded under the fore end;

- Folded with butt-plate extended to form a fore grip;

- Unfolded for firing from the shoulder.

The butt-plate doubling as a fore grip was another Czech influence, even though the Czech Sa-25/26 had a side folding butt. Firing the Rak with both handgrips had to be inaccurate, as the need to use the stock as the fore grip precluded using it from the shoulder. Also, such fore grip was extended in front of the muzzle, leading – it was feared – to heat, blast and occasional bullet injuries to the weak hand. That’s when the compensator ‘spoon’ was first devised – to fight the muzzle jump as much as to improve the safety of use. The compensator shielded the hand from hot gases, precluded extending fingers into the path of bullet, and if the firer did in fact placed his finger in it inadvertently, the slide would have stopped short of igniting the round. But fitting of the compensator also precluded unfolding of the stock with the slide in battery. The firer had to cock the weapon before handling the stock which called for sweeping his hand in front of the muzzle of the cocked machine pistol – which was intolerable for obvious safety reasons.

But nevertheless, in January 1962 the design was sent to the Radom plant, then called the ‘General Walter’ Metal Works for further development and prototype work. There, in late 1963 / early 1964 a prototype batch of 20 weapons was manufactured – already with a completely redesigned stock. The under-folder gave way to the extendable butt stock, with two machined flat stock bars connected by a small rotating sheet-metal butt-plate. After the new stock precluded using the butt-plate as a fore grip, the fore end was also redesigned. It was then made of plastic, and the part of the fore end was hinged, to form a folding fore grip. That design feature can be probably traced to the Mauser 1957 prototype sub-machine gun. Now that the weak hand holding the fore grip was safely tuck under the fore end, Rak could be fired with both hands holding the grips and with stock resting on the shoulder, which mightily improved the accuracy in burst fire, by enhancing control over the gun. The new stock and fore end were designed by two designers from Radom, Ryszard Chełmicki and Ernest Durasiewicz, who were given a Polish patent for it, No 65,772 in October, 1972. One cannot help seeing something familiar, when seeing the ultra-modern, holsterable HK MP7 with a folding foregrip and sliding-out buttstock of almost identical shape and purpose…

The price to pay for all these novelty features was a somewhat shaky and less user-resistant stock and fore end. It was found perfectly acceptable in a PDW-Class firearm for the second-rate soldiers in the 1960s and 70s, when the marksmanship training for such users was tepid enough not to show the deficiencies of the new design. On the other side, the attrition rate of firearms used in special units was high enough to cover them up, as well. If you got a bunch of snake-eaters tough enough to break a Kalashnikov rifle, then they’re poised to destroy any weapon in the world, right? To the objective eye, though, the fore grip and stock did really possessed some design flaws. The flimsy, loosely-hinged butt-plate was utterly useless for any purpose, intended or otherwise. It was designed with only one objective in mind – to fit snugly under the rear of the frame while folded. For that reason the plate was but a 2 inch long strip of flat thin metal – too short and too flimsy to matter. To obtain that all-important flush fit under the frame, one had to rotate it through 270 degrees every time it was deployed or folded, which meant there were no butt-plate catch or retainer to keep it open. Many special units of both military and police simply duct-taped them open, spoiling the only purpose it ever served efficiently. They also soon developed the practice making the folding fore grip useless – they mostly fired the Rak with fore grip folded, because the hinge was weak, and the fore grip soon developed unacceptable degree of play.

The concept of the PDW-class weapon called for a compact, holsterable weapon. The size and weight of the folded Rak were ideal for that purpose, but initially only the long, 25 round magazines were meant for it. This forced the user to carry the weapon empty – or else the long magazine sticking out from the grip would make his service life, especially the going through tank hatches, a miserable nightmare. And so the next Radom-implemented improvement was the creation of a shorter 15 round ‘holster’ magazine, which could be kept inside the grip of the holstered Rak, to give the soldier a chance to fire off those most important first shots straight after the drawing of a weapon.

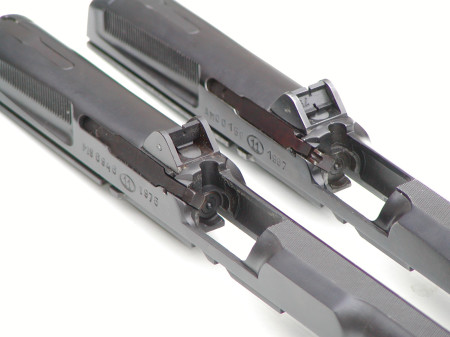

The first prototype batch of 1964 had all the plastic parts machined rather than molded – the moulds were too expensive to risk making them before the final shape of the stocks was sealed. On the left side of the slide, under the sight, all were decorated with an etched Polish Eagle – which was a clear reference to the pre-war tradition of Polish Eagle marked receivers and slides of the Radom-made firearms. The powers-that-be were not amused, though, and Radom was ordered that no other weapons be decorated that way.

After the military acceptance testing program was finished, the Rak was officially accepted into the inventory of the Polish Army as the “9 mm pistolet maszynowy wzór 1963 (PM-63)”. Already in 1964 the Radom plant started to prepare for the mass-production.

PM-63

The mass-production started only in 1967, though, and it was only in latter 1960s that the first new PDWs made their way into the hands of the Polish soldiers, soon becoming the regulation side-arm of the tank crews, scouts, RPG gunners, ATG missile-crews and drivers. Soon the downsides of the small machine pistol started to show, which gave rise to many (not always grounded) accusations leveled at the Rak. Some of these stemmed from the novelty of the design and the lack of experience on the part of the designers. Some were ironed-out during the production run – the twice redesigned magazine catch eliminated the inadvertent dropping-out of the magazine, while the redesigned stock bars catch facilitated the deployment of the stock.

Not all of the users were happy with these changes: the magazine catch, eventually buried into the grip plates, was now hard to release while shooting in gloves. Other problems were rooted in lack of knowledge and disregard for gun-safety and/or gun exploitation rules. Many rate reducer levers were damaged during re-assembly, if the lever was not positioned properly prior to re-attaching the slide. In late production Raks a special bracket was added to eliminate the lever over-travel, which cured the problem completely.

Other design changes were aimed at reduction of the unit price – we already discussed the all-steel reducer weight replacing the tungsten one, but the changes also included re-design of the frame to replace the deep-drilling of the return spring channel with just milling a groove for it. The chrome-plated all over barrel of the first Raks was replaced with a blued one, retaining only the chrome-plated bore and chamber. The captive recoil spring unit, consisting of a two-piece telescoping spring rod with end-pieces holding the spring, which enabled the return unit to be detached as one piece, was replaced by a simple spring and one piece short rod.

Two types of special replacement barrels were devised for the PM-63. One was a blank-firing drill barrel meant for troop training and movie industry alike. On the outside, the blank barrel was identical to the real one, but the bore was constricted to enable the weapon to cycle fully automatically when firing bullet-less blanks. It was designed by Marian Gryszkiewicz and Ryszard Chełmicki of the Radom factory, who were given a patent for it (No.209 398) in 1978.

The other special purpose replacement barrel was the silenced version for the special forces. The barrel was made longer, sturdier, and the part extending forward of the slide’s spoon was threaded to accept an all-metal sound suppressor designed by Marian Gryszkiewicz (this project was code-named ‘Safloryt’). As the suppressor casing obscured the sights, the suppressor was fitted with it’s own set of sights, placed on top of the casing. With the 9×18 cartridge developing a subsonic muzzle velocity, standard ammunition could be used for the suppressed version. No hard data is available as to how many of these were ever manufactured, but several hundred at most is the best ball park figure.

The PM-63 was exported as of early 1970s by the Cenzin Foreign Trade Office. It was at the Cenzin’s instigation that a prototype 9x19mm variant, called the PM-70, was designed in 1971. To accommodate for the new, more conical-cased ammunition of the significantly higher muzzle velocity and energy level, a heavier 550 g slide had to replace the old model, with corresponding changes to the grip area and magazine. Despite the initial concern, the prototype was shooting well from the very start, and while the recoil was significantly higher, mechanically it fared surprisingly well. Nevertheless, Cenzin didn’t eventually put their money where their mouth was, and only one batch of 20 PM-70 Raks chambered for the 9mm Luger were ever manufactured.

All in all, within the decade of Rak production, between 1967 and 1977, roughly 70,000 basic variant PM-63 PDW-class machine pistols were manufactured.

The Rak Heritage

For four decades the PM-63 Rak was a tool of trade for the Polish Army soldiers, and never had to be tested in real combat by the original owner. Some of it’s critics would add here ‘fortunately’, which unfortunately, is true enough. Doubtlessly, it was a remarkable achievement of the Polish designing and manufacturing capabilities, as the only – except Skorpion vz61 – Eastern Bloc burp-gun ever to be manufactured in a sizeable quantity and serving in front-line units of the major Warsaw Pact army. On the other hand, though, it is a weapon that added her own inimitable sins to the long inventory of the blowback burp-guns’ deficiencies. The wobbly useless butt plate, breaking off fore grip, exposed magazine catch were already mentioned, but the most controversial feature of the PM-63 is arguably her exposed slide-style breechblock. Scores of urban legends surround it, but not a single instance of eye-ball crushing contributed to that slide was ever corroborated, even though sporadically gas mask oculars were indeed scratched or even broken.

The sights reciprocating with the slide proved no big deal in reality, too. After all, the Rak was not designed for sniping. It is a wartime ultimate defense machine pistol, more of a saturation ‘spray and pray’ last-ditch area weapon in fact. The first shot is more or less aimed, where the rest happen to hit is a matter of interaction between the recoil, muzzle jump and physical strength of the shooter. Her accuracy was enough for self-defense, and the military users praised her as a handy, compact, well-balanced gun. A shooter unable to score at least Marksman with her was a rarity. On the other hand, Rak was practically useless – or could even be dangerous – for Police SWAT work, as a precision weapon for physical elimination of an armed and dangerous individual on a busy street. Nevertheless, back in the Commie days, when real SMGs like HK MP-5 were just something seen on TV, these were in fact used by SWAT teams of the Polish Police, and still can be seen carried now by the banking guards and several private security companies. Railway Police (SOK) also uses them, and in December 2004 there was a botched hold-up in Warsaw, when a railway cop opened up with his Rak, wounding one of the would-be robbers.

Unusual design and appealing shape of the PM-63 triggered much interest in the world. Although no foreign army ever officially adopted it as a standard-issue military weapon, some Communist police forces did. Many of these were bought by the former East German People’s Police (VoPo), where they were called the ‘klein-Maschinenpistole PM-63’ and issued to the inner security troops (Felix Dzhierzhynski Regiment) and SWAT teams (BV, Bereitschaft Volkspolizei) as well as anti-terror units. Some of these survived the fall of a Berlin Wall and even served for a while with the police of the Free State of Saxony in the re-unified Germany, along with the Polish-built helicopters. Smaller quantities of the Raks were imported by other ComBloc countries, like Cuba or Vietnam.

The latter export even resulted in a copy-cat versions manufactured in China. During the Sino-Vietnamese war of 1979, the Chinese have captured some of the PM-63, used by the Vietnamese tank crewmen. The Chinese were just on the look-out for a compact machine pistol for their Special Forces and Police, and so the state-owned Norinco factory copied the Rak and started a limited production of the Type 82 machine pistol. This weapon is known in two variations, differing in sights arrangement. One of these was an attempt at lengthening of the Rak’s sight radius by relocating the rear sight to the rear extreme of the slide. The other has sights identical to the Polish version. Both are copy-cat versions of the early production Rak, with old-style butt catch and exposed magazine catch. The Chinese Rak was also fitted with a second, front, sling eyelet, which points to the fact, that it was devised as a principal weapon, slung across the chest, and not to be holstered. The Rak copy had lost internal Chinese competition to the Mauser-Schnellfeuer-style Type 85 machine pistol, but nevertheless, the Type 82 was frequently exhibited at the international arms fairs of the late 1980s and early 1990s.

Of course, as with all other Commie compact machine pistols, the Rak was frequently used as an urban guerrilla weapon by the leftist terrorists of the 1970s. PM-63 had a dubious distinction of being featured in several high-profile cases. It was probably the East German / Palestinian channel through which the Rak reached the Red Army Faction in Germany. On September 5, 1977, the PM-63 was used during the Hanns-Martin Schleyer kidnapping. In the 1970s it was frequently seen on TV, in the hands of various Palestinian factions roaming Beirut. This was probably the source of the Rak found by the SAS Pagoda Troop storming the Iranian Embassy at the Princess Gate in London, hijacked by the anti-Khomeini Iranian dissidents in 1980. Footage from Panama, taken prior to the Operation Just Cause in 1990, shows some of the General Noriega irregulars armed with PM-63s and shooting them towards the crowd of the anti-Noriega protesters. As late as 1990s the PLO leader, Yasser Arafat, was photographed with a holstered PM-63 within reach on his desk.

The PM-63 was also used with tragic effect in Poland. On December 17, 1981, shortly after Martial Law was imposed, at the Wujek coal mine the Katowice riot police SWAT team armed with Raks, shot 17 miners protesting against the Communist violence.

Shortly thereafter a new compact submachine gun was designed, to replace the aging Rak. The Glauberyt Project led by the Radom Plant designers, culminated in the new PM-84, with enclosed bolt, but still chambered for the 9×18. Despite apparent success, it was never mass-produced. At that time the 9×19 Luger ammunition was introduced into the Army and Police, and the thoroughly redesigned PM-84 was accepted as the PM-84P. But that’s quite another story…

Technical Data

Caliber: 9.2 mm (0.363 in)

Cartridge: 9 mm x 18 “Makarov”

Barrel length: 150 mm (5.9 in)

Overall length:

Stock extended: 583 mm (23.0 in)

Stock collapsed: 333 mm (13.1 in)

Sighting radius: 153 mm (6.0 in)

Empty weight: 1.6 kg (3.5 lb)

Muzzle velocity: 320 m/s (975 ft/s)

Muzzle energy: 310 J (230 ft-lb)

Rate of fire (theoretical): 600-650 rpm

What a fantastic article.

Now I want to hear about the PM84P…

Very interesting gun and article. Pioneer was/is trying to build a semiauto version for the US market. That will probably be my only chance to handle one..

formidable….

It is worth remembering that the Rak has been copied by the Chinese, and it was close to be adopted by armed forces (eventually losing to another design).

Great article. Forgotten Weapons continues to educate me about weapons that I would not have ever seen anywhere else. Great job.

Outstanding article!!!

Thank you for putting this well written article together Leszek! I never knew about this PDW til now. Very cool gun!!

The Cuban MININT–interior ministry–has some Stechkin APS pistols. There are extant photographs of Cuban personnel with PM-63s during the pro-MPLA/FAPLA Cuban intervention into the Angolan Civil War after S. Africa and the U.S. backed UNITA and the FNLA.

I was not aware of the Rote Armee Fraktion using one during the H.M. Schleyer kidnapping…

Cancer=crab, yes?

Dziekuje//Thanks! A very detailed, informative, and well-illustrated article! I’d sure like to learn more about the Polish-made PPS43/ 1952 7.62x25mm SMG! When Che Guevara was buried in Santa Clara, Cuba, the “youth labor army” EJT mass organization had lots of those during the big state funeral… Don’t think very many have been seen since except as semi-auto handgun builds in the U.S.

For David: “rak” in Polish means also crayfish. Something like this: http://pl.wikipedia.org/wiki/Rak_szlachetny

This article is one of the best sources of information I have come across on the PM-63. What an interesting design history.

You, sir, should write a book!

No problemo – just finance a year of my living while I do, and it’s done 🙂

BTW anyone knows an editor willing to publish one in America? I think I have enough material to start seriously work on one.

A book about Polish SMGs is something I write for a long time now, but anytime I’m sure I have finished it, more and more new designs keep on creeping from under the next stone I upturn… Just two days ago I learned about a completely new WW2 Polish underground Sten look-alike with a pistol grip and under-folding stock – looking almost like Austen, but without front grip (and of course no MP 40 grips that Austen had). At least three were manufactured, as that many are shown on a photograph, plus there are several period photos of partisans holding one of these.

Leszek,

you’ve done it again. I have always liked the look of, and been curious about, the PM-63, and now I feel like my curiosity has been slaked. Dziekuju pane! To bardzo swietnie. (Apologies for bad polsky)

I particularly liked your explication of the two-stage trigger mechanism and will now hit the books and parts bins to compare it to the Czech samopals.

Re: Cubans and PDW/MPs. Che Guevara is a very special irritant of mine, and periodically when I comment on him I use a picture of him firing a Stechkin APS. It’s a well known picture taken by one of his many admirers in the Western press. (Technically he was not Cuban, but he did travel on a Cuban diplomatic passport at times). I’ve never seen him with an PM-63, but then, production was just winding up when Fate (and underperforming his press releases as a guerilla) was closing in on him.

Re: guerilla STENs. I have some parts from a guerilla STEN of unknown provenance. It was in a large shipment of STENs that were demilled, and the dealer saved these parts because they were clearly “homemade.” I do not know the origin. I’ve seen crude STENs of French and Norwegian origin, and even German ones that were presumably Volkssturm weapons. Good to know that the Armee Krajova was in on the STEN-building adventure as well.

Quite amazing that the bulk of the weapons designers survived the war and the occupation. Neither of the occupying powers wished educated Poles well. It’s got to be rough having a country with incredibly powerful neighbors and indefensible borders.

And, quite possibly, powerful prejudices based on ethnic misconceptions and outright jealousy.

@ Mr. Kevin R.C. O’Brien: Please excuse my being pedantic, or even possibly adding to your Ché Guevara irritation, but Ernesto Ché Guevara was an Argentine native who became a Cuban citizen thanks to the Cuban revolutionary regime making him one…Hence the Cuban diplomatic passport, since he was a Cuban diplomat. I have also seen the photo you describe of the Stechkin APS. As you know, he met his end equipped with the U.S. PDW: an M2 carbine, and at the receiving end of a U.S.-made M1 carbine “regalito de Mr. Dólar” carried by a Bolivian sergeant. When his remains were repatriated from Bolivia, they went to Cuba, where he is buried. There are Argentines who would like his mortal remains shipped to Argentina, his native land, primarily because aside from the tango musician Carlos Gardel [who may very well have been Uruguayan–ha!], and Diego Maradona, there aren’t too many prominent compatriots…

@ Leszek: Some folks put up websites asking for contributions toward a particular project… Given the quality of your work on Polish-designed small arms, I’d think people would contribute toward a publication. Just a thought. Perhaps an “E-book” and a print book feature might help attract a publisher? Again, very excellent write-up.

Thanks, that’s a good idea, I’ll think about that.

Another excellent article. Thanks.

Very interesting, thanks!

great article, the slide seems to have a number of assymetrical features, do you know the reason for the bulge on the slide in front of the ejection port? and the taper at the rear on that side?

The forward bulge has abutments inside for the barrel ribs, just like in Browning pocket auto slides. In order to strip the PM-63, you first cock the slide to a disassembly point slightly behind the sear catching point and rotate the safety ON to hold it in this position, then grab the front serrations on the bbl and turn it clockwise to disengage the barrel lugs from frame abutments and as you turn the bbl, the ribs enter the slide abutments inside the bulge.

I’m a bit lost with the taper you ask about. You mean those long dimples with slide serrations in them? But they are symmetrical…

I think the ‘taper’ the OP is referring to might be the serrated area at the back of the

‘slide’, which widens to the back. I presume it widens to further minimize the danger of slipping and therefore facilitate cocking the slide. On the right hand side this taper does not reach as far as on the left, because the extractor spring is situated there an needs a bit more material on the slide.

And then I have to file a complaint: this superb article in Forgotten Weapons by Leszek Ehrenfeicht led to a serious onfection of ‘must have’, which could only be cured with the acquisition of an arsenal-grade, never used, albeit deactivated PM 63 which currently resides on my workbench. Can I make anyone responsible and charge him (or them) with the costs inflicted an me?

Congratulations on your recent find, Michael! It was wonderful to hear about it. As for the “serious infection” and responsibility thereof, I’m afraid no-one here will be able to help you as we mostly all have the same dreaded “disease” :).

Excellent in every sense, thanks! Great photography too, btw. This article is the best single reference I ever read on the PM-63 machine pistol. I look forward to reading more superbly researched articles like this one by Leszek Erenfeicht, especially on Polish guns (as already someone said, the PM-84P could be a nice follow-up).

Btw, I am curious on how the Chinese Type 82 clone compares, build quality-wise, to the original Polish-made “Rak”…

Outstanding writing!

Before purchasing the PM-63 the East Germans developed the ‘Klein-Maschinenpistole IX. Parteitag’.

http://farm7.static.flickr.com/6162/6199729342_3eecf15eeb.jpg

Didn’t go into production due to costs; and yes, there’s a spare mag in the foregrip.

Only the DDR would have named a weapon for the “Ninth annual party congress.” Lord love a duck.

Then again, another German government tried to name a small car the “Strength-Through-Joy-mobile.”

Interesting looking gun. Like an attempt to build a Beretta 93 in a prison workshop….

Very interesting and informative link on yet another rare and definitely “forgotten” weapon, Fidel. Many thanks for sharing!

@ Ian, Pan Leszek, Earl Liew, the Weaponsman and Gospodin Popenker:

https://forum.ioh.pl/viewtopic.php?t=7190&postdays=0&postorder=asc&start=475&sid=d06c7dd36eb53a204a7e448e0e83fd81

Sorry lurkers, Google won’t translate.

Oh, that’s just the “Guess That Weapon” thread at the Polish IOH.pl forum, with Remov asking about the 9th Parteitag machine pistol, and a discussion whether it is IX or XI, because the Suhl museum captions it IX Parteitag, and BWB calls it XI in some catalog.

What else is there to say to Leszek, except perhaps “c’est magnifique”! Thanks so much for a thorough, well-researched and comprehensive treatise on the PM-63. I remember reading assorted articles about the PM-63 many years ago, some of which were informative and interesting, but I can honestly say that the whole lot put together would still fall far short of Leszek’s in-depth analysis and solid technical evaluation. He really deserves to be universally acknowledged and published.

Here’s an older blog post from M. Bane about the PM-63… Mostly firing impressions:

http://michaelbane.blogspot.com/2012/09/new-all-time-favorite-sub-gun.html

I had such weapons in the army with the serial number AM 01393 .

Guys, what about the long-standing myth that “RAK” is an acronym for “Reczny Automat Komandosow” (Commando Hand-held Automatic – the word “Automat” was often used in reference to SMGs and automatic rifles)? Is it true or not?

Have you read the article at all?

Ah, my bad, missed that paragraph. Sorry.