The TZ-45: Italy’s Late-War SMG with a Special Safety

Italy and submachine guns – with these words usually three large names come to one’s mind: Villar Perosa, Beretta and from the 50’s-years Luigi Franchi. Until the end of World War Two only few other companies tried to break into the market dominated by Beretta. Only the model 1943 of the Fabbrica Nazionale Armi di Brescia and the TZ-45 of the Armaguerra Cremona went into serial production.

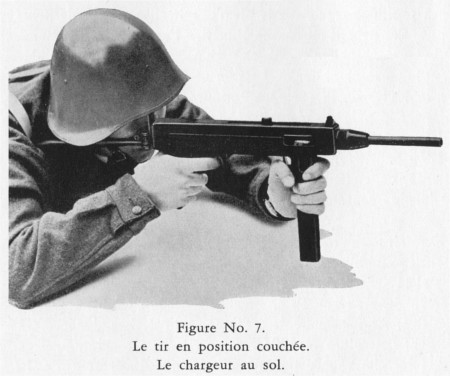

The L-shape grip safety is located behind the magazine well.

At a first glance the TZ-45 looks like a typical submachine gun of it’s day: A simple blowback system (open bolt), constructed of sheet metal parts fixed to a tubular receiver. Only the grip plates are made of wood. The retractable steel rod stock resembles the American M3 (Grease Gun). In the pushed-in condition the ends of their two rods are resting in a holder plate beneath the barrel. When shooting from vehicle hatches this plate also prevents an accidentally withdrawing of the weapon. That’s a similar safety precaution as the hook-style barrel rest of the German MP 38 and 40.

But the TZ-45 has some more special: An automatic grip safety. Such a thing has never been used on a submachine gun until then. At that time, apart from saving raw materials, the needs of a simple and speedily manufacturing process had priority before all. Little attention was given to safety. Not so with the brothers Tonon (“Toni“) and Zorzoli Giandoso, when they were working on the draft of their first submachine gun. They created a very simple but effective safety which became active by itself. All other submachine guns only possessed manual safety devices.

The automatic grip safety wasn’t a mold-breaking innovation. Already some early self-loading pistols like the German Pistole 08 or the Colt M1911 featured a grip safety on the back side of the grip, which was only released by a firm clasp of the shooter’s hand. In German it’s called “Handballensicherung” (heel-of-hand-safety). But for a submachine gun this construction was too complex. Therefore the brothers Giandoso transferred the safety to the outside of the receiver behind the magazine well. It only consists of a spring-suspended L-shaped lever, which projects into the receiver and blocks the way of the bolt. Only if the second hand clasps the magazine well firmly, and presses the lever forward, it releases the bolt. As soon as the shooter’s hand loosens, the lever snaps back again and the weapon is safe. No matter whether the bolt is in its front or rear position.

Despite all adversities and the foreseeable end of the war the Giandoso brothers succeeded in manufacturing nearly 6000 weapons in their own company “Armaguerra Cremona“. A majority went to the units of the R.S.I. (Repubblica Sociale Italiana) in Northern Italy to fight against partisans. The magazines of the TZ-45 are identical to the Beretta submachine gun magazines, so in mixed armed units they could be easily swapped during combat.

After the war some weapons were brought to England and the USA for trial measures, but were soon classified as outdated. However the Burmese government bought the rights on the construction and introduced the weapon as “BA-52” in their army. For support during the preparation of the serial production Tonon and Zorzoli Giandoso went to Burma. Afterwards their trail was lost. Production numbers and the period of official use in the Burmese army are unknown.

The safety of the TZ-45 was foolproof – nevertheless it did not continue to become generally accepted. After the war more quality and comfort were required again. Numerous submachine guns received an integrated grip safety like the pioneer ZK 476 from Czechoslovakia, the UZI from Israel or the Beretta models from 1955 on. Thus also a crucial disadvantage of the TZ-45 was eliminated: both hands had to grasp the weapon when shooting. One-handed shooting, e.g. after being wounded, was not possible. Same with different aiming styles during an attack. That could be a crucial disadvantage in fighting. Furthermore the safety had not been optimally designed: The shooter had to press the shorter arm of the L-shaped lever, which required a strong grip due to the leverage and the strong spring. If the hand fatigued, the lever began to touch and slow down the bolt moving inside the receiver. This often led to malfunctions.

A new attempt: The problem was recognized, namely by the Danes. The company Dansk Industri Syndicat A/S (DISA) from Copenhagen was one of the few, that built a submachine gun with grip safety at the magazine well again. In the year 1946 their “P.16“ went into production, better known as the “Madsen 1946“. The unusual construction with the laterally hinged receiver featured a more favorably placed lever. The bolt is caught by the lever’s nose just before it’s end position. To hold the bolt in the rear position a manual sliding-safety was used. The grip safety seemed to have worked satisfactorily in this case, because it remained unchanged with all revised subsequent models (M.1950, M.53 and Mark II). Beside the Danish police the weapons found their way mainly to South America and Asia. Larger quantities were sold to El Salvador, Paraguay, Guatemala, Colombia, Thailand, Korea and Indonesia.

Despite the success of the Madsen MPs the history of the grip safety at the magazine well already ends with these two weapon models. No more other weapons manufactured in series possessed this safety.

Technical Specs (TZ-45)

Caliber: 9x19mm

Length, overall: 33.5 in (851mm)

Length, stock collapsed: 21.5 in (546mm)

Barrel length: 9 in (229mm)

Weight, unloaded: 7.0 lb (3.2kg)

Magazine capacity: 20, 30, or 40 (uses Beretta M38 magazines)

Rate of fire: 600 rounds/min

The author wishes to thank Al Houde of the U.S. Marine Corps Museum at Quantico, VA for his assistance.

Like Michael Heidler’s work? Check out his books at his web site, or see our review.

I don’t agree with some of the assertions about the so-called disadvantages of the forward grip safety.

One, by separating the function of the grip safety and trigger, it not only makes the gun easier to maintain, but also it becomes a lot less AD prone due to sympathethic finger syndrome. When one grips the subgun in a hurry in stress, one engages the grip safety and at the same time, more likely to pulls the trigger even when not warranted, out of habit.

Also, even when one doesn’t actually engage the trigger after activating the grip safety, when one bumps into an obstacle, one tends to form a hand into a fist, engaging the trigger unintentionally.

Also, by separating the grip safety with the trigger function, one can have finer control of the trigger finger, making the subgun more accurate in practice, plus this improves the weapon retention/control for those with smaller hands/fingers, or when wearing thick gloves.

There is no such thing as one handed firing of full auto weapon, outside the Hollywood.

Btw. I don’t believe Madsen’s forward grip safety is an improvement over the Italian one. Italian grip safety works with bolt either forward or rearward, Madesen only works with the bolt forward. This not only complicates the manual of the arms, but also slows down the engagement process when the bolt is rearward, plus more accident prone.

The stronger grip the Italian one requires is not a disadvantage. One has to grip the forward strongly to be able to control the full auto burst anyway. This prevents the bad habits forming.

There is something wrong: Tonon (or Tony) and Zorzoli Giandoso never existed.

Tonon (firstname) was a Colonel of the Royal Army;

Zorzoli (firstname) was an industrial designer from Torino,

Ermenegildo Giandoso and son was a factory near Brescia.

So two individuals an a factory, not two brothers.