As everyone is aware, the M16 suffered from maintenance and reliability problems early in its deployment to Vietnam. While working to resolve these issues, the US government wanted to find a replacement weapon that would be more suitable to guerrilla type use to supply to insurgent forces. A contract for to this end was awarded to the TRW corporation in 1971, and the result was the TRW Low Maintenance Rifle.

Rather than judge the design by first glance, it’s worth looking at it more closely – there are a lot of different things at play in this rifle. The information I can find doesn’t discuss whether this was intended to be manufactured by foreign groups with limited resources, but that seems to have been TRW’s thought through development (or alternatively, they wanted to be serious about minimizing manufacturing costs). The rifle does use the standard M16 magazine and M193 5.56mm cartridge (although at least one of them was used experimentally with the XM216 flechette round).

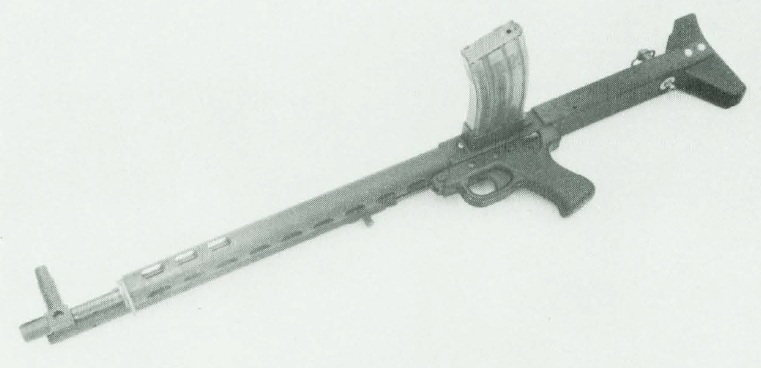

The rifle is operated by a long-stroke gas piston, a system know for reliability (the piston and gas tube are on the right side of the weapon). The bolt uses a roller locking system similar to the German MG42, with the rollers located on the top and bottom of the bolt so as to not interfere with the magazine feeding in from the left. Roller locking systems like this are well suited to cheap and easy production, with reduced machining and heat treating requirements. The rifle fires only in full-auto from an open bolt, which is again a very simple system. The trigger simply holds down the sear allowing the weapon to cycle continuously until the trigger is released and the sear catches the bolt. This cuts the number of trigger mechanism parts at least in half compared to a typical select-fire closed bolt system. In this case, TRW actually just used the grip and trigger assembly off the M60 machine gun. The receiver and buttstock assembly appear to be pretty simple pieces, and are connected together by a simple pin instead of using interrupted threads or lugs or other cleaner-looking but more expensive interface.

The open bolt and automatic-only operation may not have contributed to exceptional accuracy in practical use, but the objective here was reliability in harsh environments (hence “low maintenance rifle”). The bore was chrome lined, and the internals were coated with what is described as a semi-permanent dry film lubricant, to avoid attracting dirt and dust (the manual recommended inspecting and touching up this lubricant every 2000 rounds). In an unusually prescient move, the gun was also designed to automatically pull a dust cover closed over the ejection port when the bolt was all the way back (remember that since this rifle fired form an open bolt, locking the bolt open would have been the “ready” condition). The cover would be opened up automatically as the bolt went forward to fire.

We have not found any testing reports on the LMR’s performance, but we suspect it would have been very effective. Unfortunately for TRW, by 1973 American troops were leaving Vietnam and the project was no longer considered important. It was cancelled before any rifles were actually put into service (in fact, one could think of this weapon as an analog to some of the German Volksturm designs).

Photos

Manuals

Remember Twilight 2000? To me this design always made more sense than the M16EZ the game designers came up with.

Heard of the GDW game. Never played it, though did all the SF stuff. How’s it play? Kinda like Dark Conspiracy or Traveller?

The First version was nothing like Dark Conspiracy or the later Traveller versions. That’s the one, IIRC, that had the “M16EZ”.

The 2nd Edition of Twilight:2000 was the game engine used to create Dark Conspiracy and the Traveller: New Era games.

looks a little bit like the german fallschirmgewehr 42

@McThag: Wow I hadn’t thought of that game in years, though it was one of my favorites. Thanks for that bit of memory! I agree, wonder if the machinist’s drawings are available in the public arena?

I have found some testing data and alot of other data for this, Its in the 1977 edition of jane’s infantry weapons.

N.P.

could you possibly share any TRW Low Maintenance Rifle data you have?

Make a heavier barrel turn the magwell downward and put a beta mag on it.

Simple effective LMG

Turning the magazine well downwards would mean a large amount of redesigning and it would complicate the mechanism and cost more to manufacture. I would think a beta mag would work ok in it as is but i dont know if the magazine release could be accessed after attatching it. The barrel seems to have enough thickness to put up with some amount of sustained fire. It would be have to be treated less than a LMG more like a LSW/IAR (eg:like a HBAR L2A1 (FNFAL), fired in short bursts). I guess using 20 and 30 round mags would give some time for the barrel to cool.

I wonder why they used a gas system at all when a roller locking mechanism doesn’t really require one? The Spanish Ameli is also in 5.56 using a roller locking bolt and is based on the MG-3 which is just the modernized MG-42, and none of these use a gas port, piston, or tube. (Just curious.) The Ameli dates from 1974, about the same time period. Seems like it would have been much simpler, but perhaps not as reliable or something? Never heard of any problems with the MG3 or the Ameli either for that matter. Both are reportedly more reliable than the M-60 which is gas operated, although I read that the E4 version is supposed to be better than the earlier ones. Sure would be pretty cool to see one of these redone in the little FN 5.7 round using a simple open bolt blowback mechanism and those cool right-angle 50 round magazines! Feed it left to right or top to bottom, either way would be very cool to see.

A simple gas system (gas piston that is) would likely cost less to produce while being less likely to malfunction due to lack of cleaning or less than perfect ammo.

Roller locking requires precise machining, and wears out faster. Not that wearing out was likely an issue for the intended use of this design. Roller locking was an absolutely ingenious invention, but other than HK or firms making CTME designs I’m not aware of any arms manufactures using the concept today. Sort of like the Wankel engine of firearms.

Roller delayed blowback (which is what you’re actually talking about – the HK designs aren’t really “locked”) is fairly ammunition sensitive.

I remember a decade or so ago that some South American company came up with a very low cost rifle. It featured short recoil opperation, M-16/STANAG magazines and trigger parts from some other selectfire rifle already in mass production. Cost was “Less than $100.00” back then, even with their antique machine tools! Less now if made here or some place else with more modern machinery.

Anyone remember the name of said weapon, or it’s maker?

One thing that needs to be taken note of is that this a roller locked breech mechanism and not a roller delayed mechanism. The two are significantly different in the way they function. As pointed out in an earlier comment, a roller delayed system (Cetme, H&K, StG57 etc) does require a relatively involved and careful series of machining operations to achieve the critical angles, surfaces and tolerances. As has been mentioned everywhere, perhaps to the point of inanity, in the roller-delayed mechanism, the breech is never really locked but forced to open against a severe mechanical disadvantage. The careful and elaborate machining is necessary to achieve this and thus relatively more expensive

On the other hand,a roller-locked breech mechanism achieves breech sealing by a more conventional approach. The breech is positively locked by rollers forced out (usually by the firing pin) into corresponding abutments in the receiver or trunnion. The system is somewhat forgiving and other than uding rollers to achieve lockup, it isnt all to different in essence from other ‘wedge’ type locks.

In this system, the movement of the rollers are actuated by an ‘external’ or ‘indirect’ means- either short/long recoil or gas piston.

The MG42 is a roller locked system that uses the short recoil stroke of the barrel to actuate the roller movement.

I don’t see that the machining for roller delay is complex or super precise at all, the recesses can be simple drop in parts like the Sig 510, and the angled faces on the locking wedge are just that, one angle around 50 deg , not hard to manufacture. The mathematics work is all in the design, which has already been worked out. I would say a much simplified Sig 510 would be easier to machine than an AR’s helical cam path and multitude of lugs.

Cleaver but given how much a decent semi automatic cost you’d think some company would buy the patent and produce cheap yet effect semi automatics. Any one with a gun permit and $150 would interested my interest has been peeked. The gun would be useful in a SHITF or get around gun control laws.

Part of the simplicity and ease of manufacture in thisstems from the simple open bolt, full-auto design, do to legality issues in most of the western world this makes the TRW unviable in its current state.

A semi-automatic conversion might push the rifle to a point where it’s not significantly cheaper to manufacture then other options, especially when you factor in the benefits of other platforms like the ARs modularity, accuracy and extensively battle tested reliability.

The TRWs estimated retail price for this rifle was $130, adjusted for inflation that’s $800 today, sure additional cost saving measures that developed over the last 50 years could be adopted, but you can get a decent ar15 for 500 bucks brand new, and a used one thats really just as good for even less.