九七式自動砲: The Japanese Type 97 20mm Anti-tank Rifle

by Christopher Bailey

In the middle part of the 1930’s, it became apparent to nearly all observers that another war was on the horizon. Recalling the lessons of the First World War, nations around the world each began their own program to design and perfect a man-portable anti-tank weapon. The most obvious solution at the time, and the one that most designers chose as their starting point, was the World War One German concept of an “anti-tank rifle”. The first such gun, the Mauser 1918 Mauser T-Gewehr, was itself simply a scaled up Model 98 rifle. Chambered for a newly developed 13mm round, the T-Gewehr was a capable and effective battlefield rifle, and further development of this line of weapons was a reasonable solution at the time.

From this prewar “arms race” came a number of competing designs, amongst them the Polish Wz-35, the German PzB 38, the British Boys Rifle as well as the Solothurn series of commercial guns. These rifles, all using different mechanisms, show off a variety of design compromises. Some used a small high-velocity bullet fired out of a light weight gun, while others used a large projectile fired out of an equally heavy weapon. The middle ground (that of a medium sized round) was also employed, though it was largely overlooked by most designers Not to be left behind by these European developments, the Empire of Japan began its own program in 1935, culminating in 1937 with the adoption of the Type 97 Anti-tank rifle.

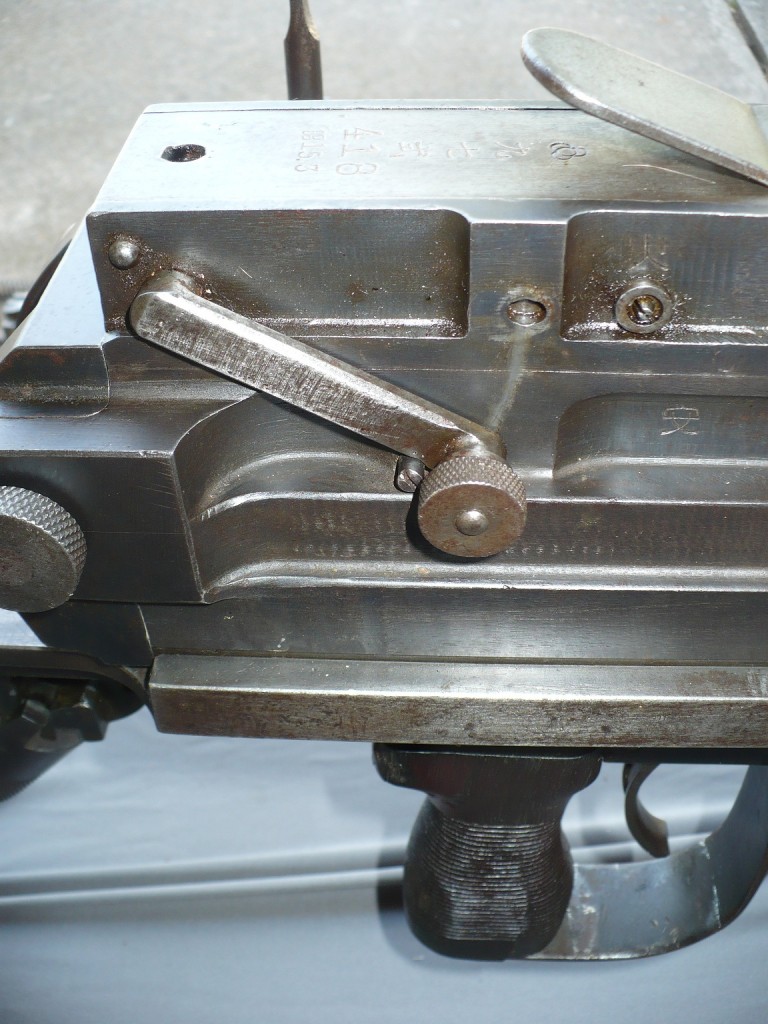

Chambered for the powerful 20x124mm cartridge, the Type 97 is a magazine fed, gas-operated weapon that fires from an open bolt. More like a small artillery piece than a traditional self-loading rifle, the whole receiver and barrel assembly of the Type 97 actually slides front-to-back during firing. While designed only for semiautomatic fire, there are reports of guns firing fully automatic. These seem to be either mechanical malfunctions or simply accounts of the Type 98, a fully automatic machine cannon derived from the Type 97.

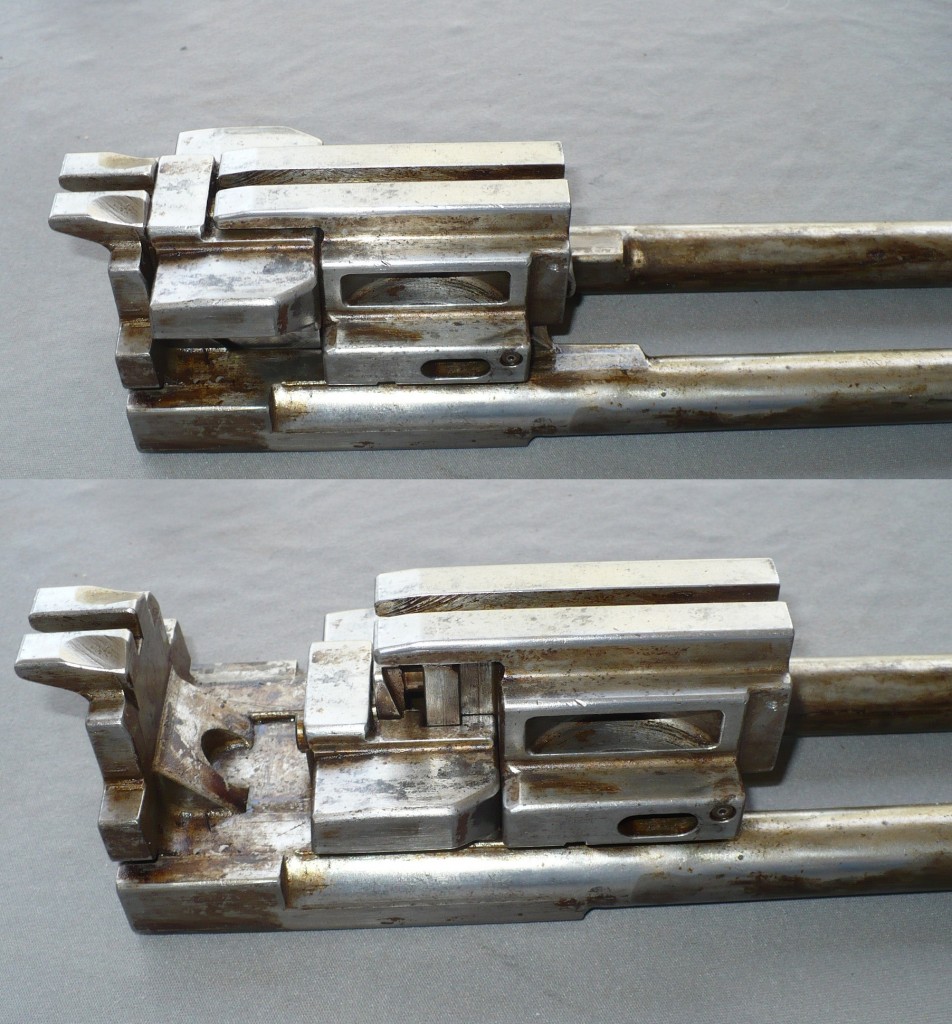

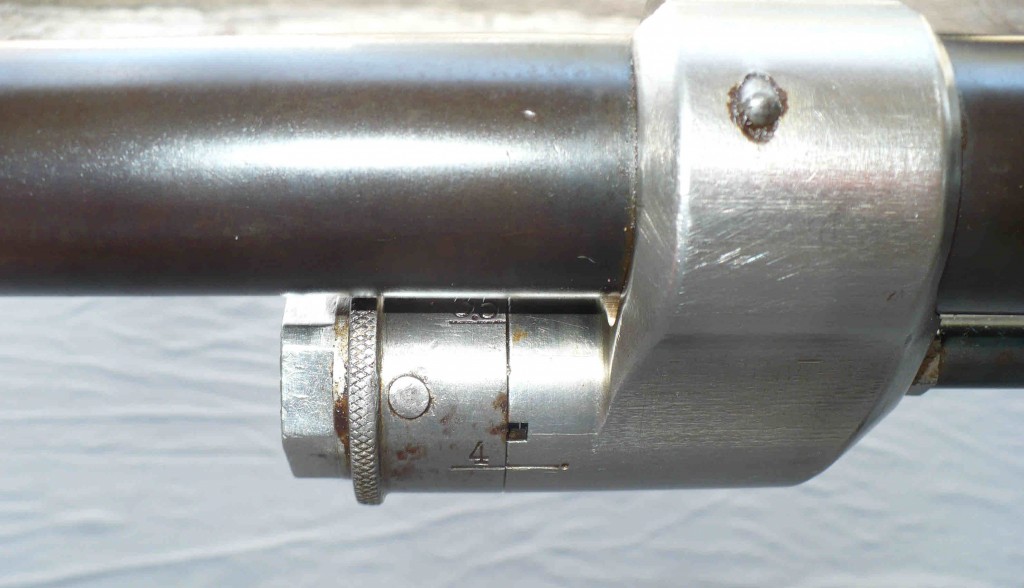

When fully assembled with its armor shield and carrying handles, the gun weighed in at an astonishing 150 pounds. Unlike other heavy designs that came equipped with wheeled mounts or skis, the Type 97 was carried by its crew much like an injured man on a stretcher. This heft, coupled with the guns accessories and ammunition would have certainly place a large burden on the nine man crew during cross country operations. The barrel, which could be removed for long distance transport, was locked to the receiver using an interrupted thread mechanism.

Once the gun had been carried to its destination, the crew would adjust the three legs and lower the weapon into its firing position. To cock the weapon, the charging handle located on the left side would have to be pulled fully to the rear, with a loud “click” letting the shooter know that the sear had engaged the bolt carrier. After ensuring that both dust covers were open, a loaded magazine would then be locked into place on the top of the gun. At this point, the gun was ready to fire.

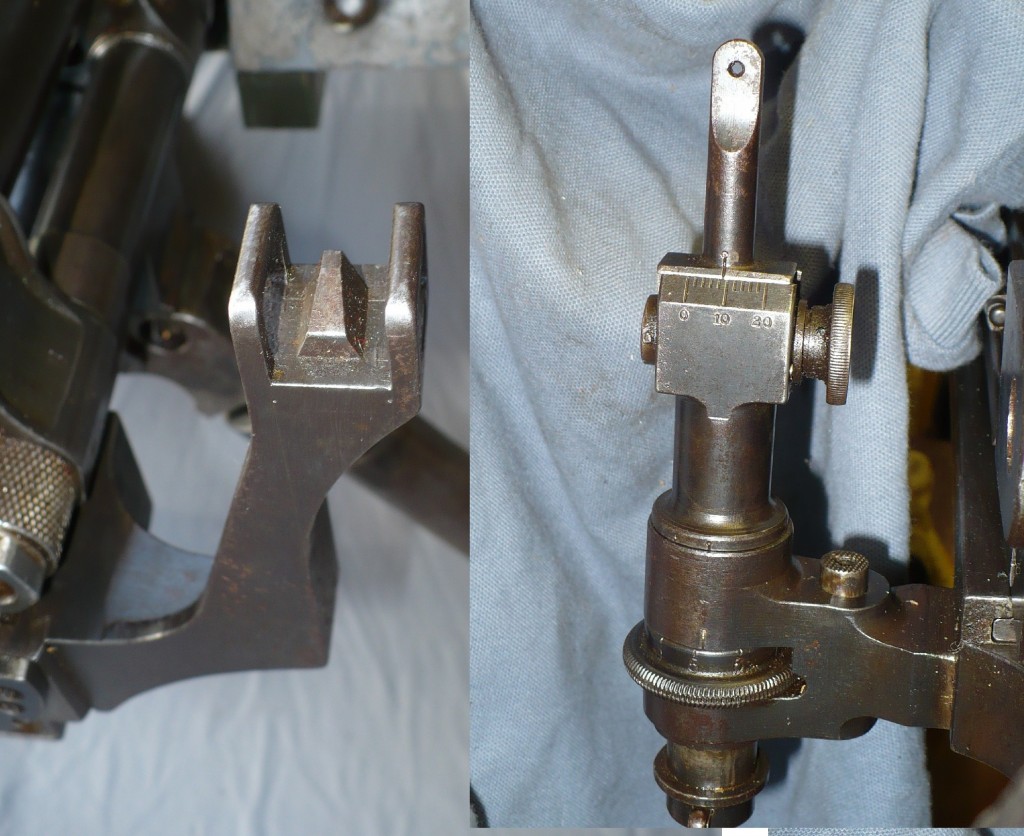

After loading the weapon, the gunner would lay the gun on his target. This was accomplished using a rear peep sight and a blade front sight. Traversing the gun was actually somewhat difficult, requiring the gunner to lift the rear of the heavy gun with his shoulder before shifting it left or right. Elevation could be adjusted in the similar manner, or by raising and lowering the rear monopod leg via its knurled grip. An assistant gunner would grip both forward legs to steady the gun during the firing, a position that must have been unnerving to those so assigned.

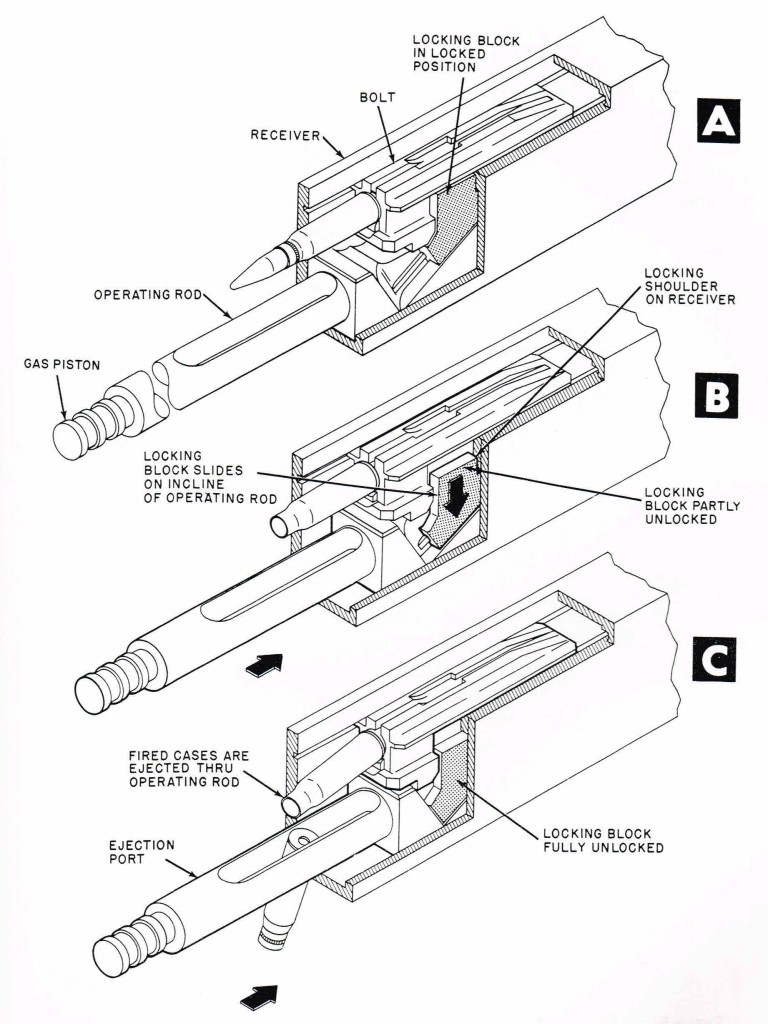

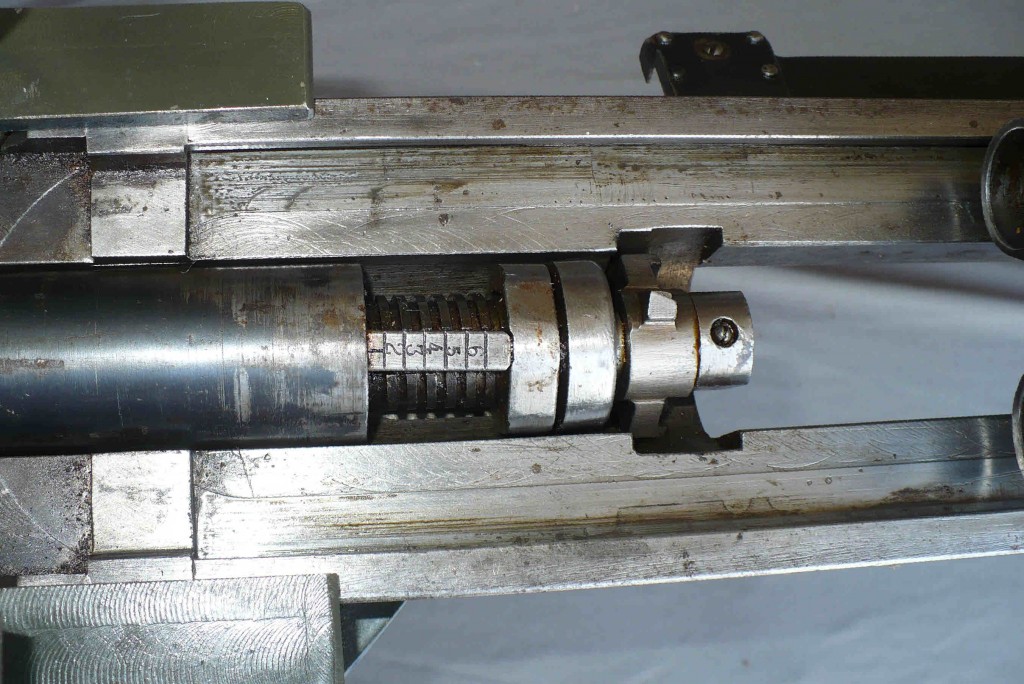

Once the gun had been appropriately sighted, the trigger would be pulled firmly to the rear, releasing the bolt carrier assembly. Driven forward by spring pressure, the bolt would strip a round from the magazine, feeding it into the chamber. The bolt carrier, continuing forward, would lock the action by forcing a locking piece into cutouts located in the sides of the receiver. Once fully locked, the firing pin would be struck be the carrier assembly, firing the cartridge.

As the projectile traveled down the barrel at 2,640 feet per second, some of the propellant gas was diverted into a regulated gas tube assembly located underneath the barrel. The gas acted directly against two integral gas pistons on the bolt carrier, forcing the bolt assembly to the rear and unlocking the gun’s action. The fired case was then extracted by the bolt and thrown out the bottom of the gun by an ejector mounted in the top of the receiver housing. Once fully to the rear, the sear would again catch on the bolt carrier, locking the action open until the trigger was pulled once more. Simultaneous to this internal action, the whole barreled action would cycle both forward and to the rear, its movement being slowed by the recuperator system mounted in the lower receiver. This additional complexity served to somewhat soften the recoil experienced by the shooter.

Production of the gun began in 1938 at the Kokura Arsenal, a facility best known for its small arms production throughout the Second World War. First seeing combat against the Red Army at the Battles of Khalkhin Gol in 1939, the Type 97 proved to be a disappointment to the Japanese military, with its 20mm round performing poorly against Soviet BT series tanks. This is somewhat surprising given the fact that wartime American testing demonstrated that the projectile could pierce about 30mm of armor at 250 meters range.

When one also considers the complexity of the gun and the difficulty of manufacture, it isn’t surprising that production of the gun was terminated in 1941 after some 1100 had been completed. As the war turned against Japan in 1943, the Nihon Seikosho Company (Japanese Steel Works) tooled up and produced another 100 guns, after which no more were made. Despite its limitations, the Type 97 continued to be a front line weapon throughout the war in the Pacific, usually being employed in a prepared static defense position. Very few examples of the gun survive today in either private hands or museums, almost certainly due to its bulk and great weight.

Technical Specs

Caliber: 20 x 124mm

Mechanism: Gas-operated open-bolt semiautomatic

Length, firing position: 82.5 in (2096 mm)

Length, traveling position: 99.5 in (2527 mm)

Weight, complete: 150 lb (68.1 kg)

Weight, less shield and handles: 115 lb (52.2 kg)

Barrel length: 41.875 in (1064 mm)

Rifling: 8 groove

Magazine capacity: Seven rounds

Muzzle velocity: 2,640 feet per second (866 m/s)

Total production: Approximately 1200

Were these ever used in scout or light armored vehicles, like the Boys Rifle in the Universal Carrier?

If i remeber well a variant of this was mounted on zero fighters called type 99 but i may be mistaken.

Actually it was two type 97 LMG (7.7mm)and two type 99 autocanons (japaneese version of the Oerlikon). aparently this rifle was never mounted on anything.

“Say hello to my big, barking friend.” I assume that this would beat the Boys Rifle in dishing out damage, since it’s a semi-auto/full-auto rifle firing an explosive shell. And the Japanese gunner was protected by that annoying shield too! Considering that it is impractical in most scenarios, I hypothesize that the best setup is as follows:

The gunner and his assistant position their gun near the top of a wooded hill and camouflage the rifle. They will wait for the enemy to approach. When the enemy is close enough they will pick off the enemy commander, radiomen, and just about anyone who isn’t a front line rifleman. Enemy machine guns and heavy weapons are also on the priority list since they cannot be fired in ad-hoc positions safely.

Unfortunately, one would require at least five of these anti-tank guns to make the above strategy effective. A single gun might kill the enemy commander, but the rest of the opponents would then resort to either spraying the hill with machine gun fire or call upon heavier strikes from artillery or even air support.

Does anyone have any ideas as how to use this gun properly in battle?

Like any “heavy rifle”, this monster’s primary mission would be as an Anti-Materiel Rifle (AMR). The mission would be the long-range (1000+ meters) destruction of high-value soft targets that would otherwise require sneaking up close and planting a PE charge. The API-T round would have been especially effective against fueled and armed fighters, etc., sitting on an airfield. To say nothing of the havoc it could cause if you got a shot at a fuel truck- or a fuel dump.

With a couple of full magazines and a loader/spotter, you could turn a fighter field into an all-night barbecue in under two minutes. Then abandon the rifle and GTHOD. Cost to you; one rifle. Cost to the enemy; a dozen or so combat aircraft, or a fuel dump, destroyed.

I’d say you come out ahead on the deal.

I’m not sure accuracy would be up to long shots (900+ meters) on single individuals, so potting generals wouldn’t be a viable mission. But a P-40 (or, for that matter, a MiG-29) is a lot bigger than a Chesty Puller.

cheers

eon

I believe I read somewhere that these also made effective anti-boat weapons. Like other Anti-tank Rifles of the time, the Type 97 would not be very good at taking out frontline combat tanks like a Sherman, but it could take out the plethora of lesser combat vehicles like Amtracs, landing craft, artillery tractors, trucks, jeeps, etc. Or it could be used as a counter-sniper weapon like the Finns did. Overall, though its original role was eclipsed, the Anti-tank Rifle in WW2 was certainly not without use – though some countries failed to realize this.

Beach defense, anti landing craft role

I have a few questions.

One, how many type 97s are there left?

Two, who owns this particular example?

And three, have you ever fired one?

I once had a volume of “—Infantry Weapons of WW2” by Mastergunner Ian V. Hogg. (The English army has probably been preserving that weird rank for 600 years+.) In the section for anti-tank rifles, he claims to have fired the Type 97 on full auto or was it really fast semiauto? Either way, he described the recoil as being relatively mild, more a “series of powerful shoves than punches”.

As for deployment, well one idea that comes to mind is beach defense for island garrisons. OK, by 1943 it can no longer punch through a tank, but could it punch through an LCI to cause carnage amongst troops massed behind the front drop ramp before they get to the beach?

Eon, what is this nonsense about abandoning the AMR? If it doesn’t have a bayonet, a samurai will defend it with his sword!

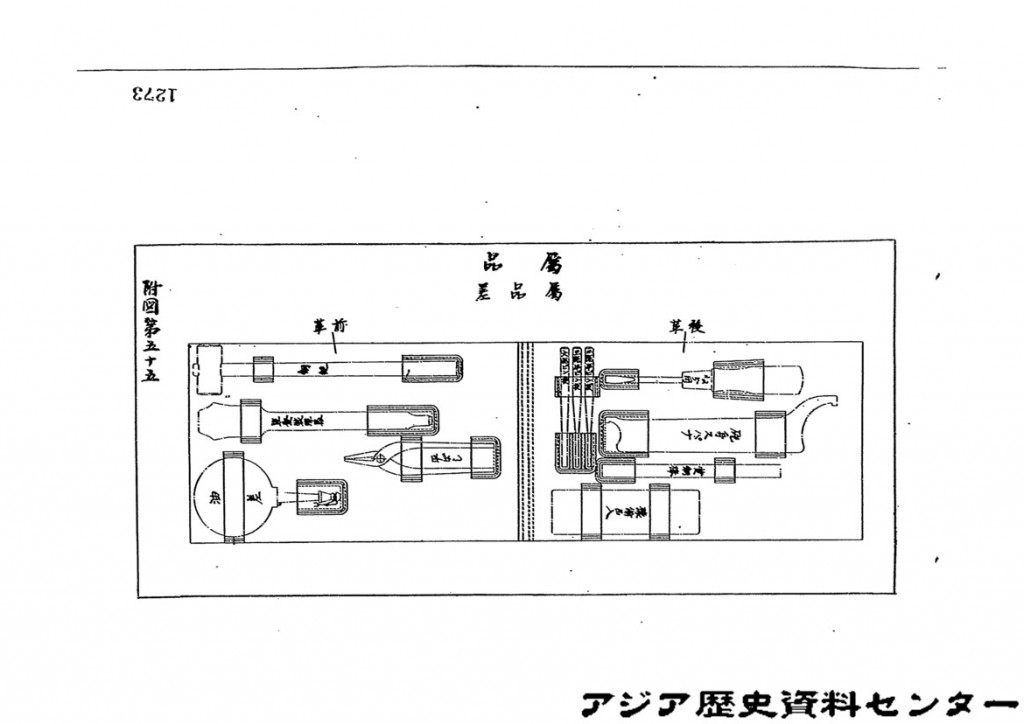

The image with the number “1273” in the lower right corner is actually upside-down.

There is a further possible explanation for the story that this gun fired on auto – which it certainly was not designed to do and which I agree was probably the result of a failed sear in captured examples. A modified full-auto version was developed as an aircraft gun for the Army. In fact, two versions: the Ho-1 (for flexible mounting) and the Ho-3 (fixed). These both used double-drum magazines (15 and 50 rounds respectively) but didn’t see much use – they only fired at 400 rpm. I think that the first version of the aircraft gun may have been referred to as the Type 97 initially.

A possible explanation for the discrepancy in AP performance was that Japanese 20mm AP projectiles were available in different levels of steel hardness (presumably for manufacturing/cost reasons). The soft steel proj was painted black, the medium hardness one had a green band added and the hardest version had green and white bands, as shown in your example.

The Type 98 AA/AT gun used more powerful ammo with a bigger cartridge case (longer at 142mm and wider too).

In the caption for the photos of a blank and APP round, it is written that a small strip of Lead foil was loaded in with the NC powder to reduce fouling.

More likely, this was Tin or a Tin/Lead alloy foil, added to reduce MUZZLE FLASH. This was a common WWI-WWII era artillery muzzle flash suppression technology… See the remarks on prior art in this patent.

https://www.google.ch/patents/US2304037

HEAVY. Not mobile. Needs 9 people crew.

Too heavy for a rifle, too light for a gun.

Clumsy, stiff, immobile…

A lot more than 1,200 of these were produced. I was allowed access to a “government” armory where there are two of these being preserved. One of which is serial number 5,1XX and is dated 18.2 (February of 1943). I think this is pretty important information considering how many of these may or may not have actually been fielded.