Think about the really stereotypical service pistol for the 21st century (so far) – it would be something with a polymer frame, large magazine capacity, minimum of manual controls, and a striker with a safety built into the trigger pull. Like a Glock or Springfield XD or Smith and Wesson M&P. Everyone in tune with the times seems to have come to an agreement that this is the ideal set of features for a “serious” service sidearm. Now think back to the 80s (having been born in the 80s, I’m judging the second-hand, but bear with me). What features were really desirable on service sidearms back then? Large caliber, manual safety, and stainless steel (and lots of it), right? In that case, I present a quintessential 1980s combat pistol:

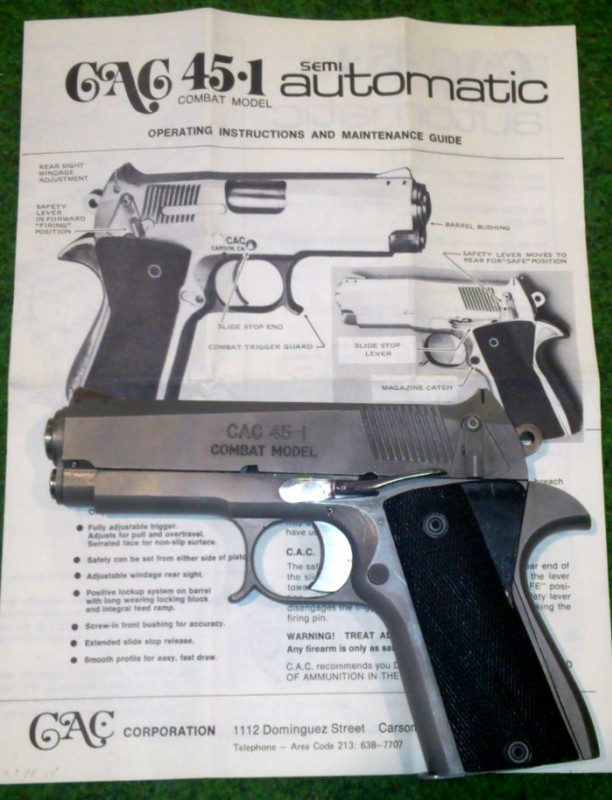

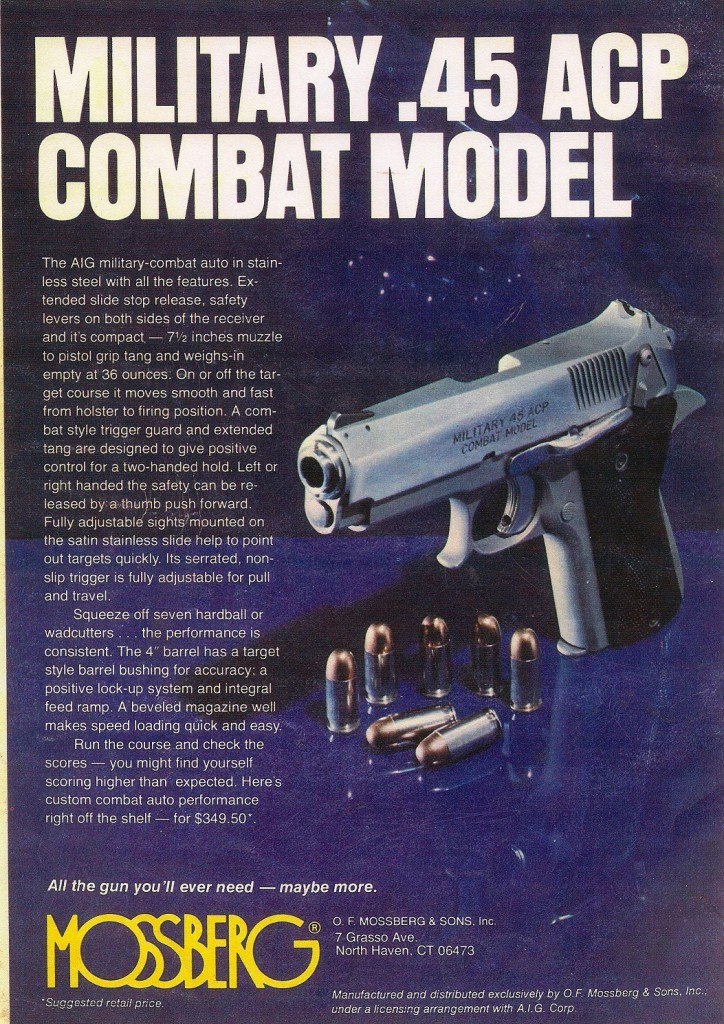

This is the Combat Model .45, made by a company called CAC for Mossberg. It was designed by none other than Bo Clerke (of barrelmaking notoriety, as well as the .38/.45) first shown to the public at the 1979 SHOT Show. Mechanically, it is basically a 1911, with design changes made to address what were considered shortcomings in Browning’s venerable pistol. The differences are:

- No grip safety. Instead, it has a huge beavertail to protect the shooter’s hand from the hammer.

- Rear sight adjustable for windage by a small screw.

- Massively extended slide release, which can be operated by the shooting thumb.

- Safety (ambidextrous) mounted on the slide; push forward to disengage.

- Cam slot in the barrel (like the High Power) instead of Browning’s swinging link.

- Threaded-in barrel bushing, theoretically for improved accuracy.

- Full-length guide rod for the recoil spring.

- External extractor.

- Shortened 4 inch barrel.

- Pivoting trigger rather than Colt’s yoke type.

- Beveled magazine well.

- And, of course, the entire gun is made of stainless steel (all 36 ounces of it).

As you can see, many of these updates are not exactly original to this particular pistol. My Ballester-Molina incorporates several, as does the High Power (which was Browning’s follow up to the 1911, although he died before completing it). A couple anachronisms are also evident, primarily the “combat” style trigger guard spur. To quote Dr. Ralph Glaze’s article on the CAC .45 in the 1979 Guns & Ammo Annual:

Since “Combat” shooting requires the use of a two-hand hold, it has long been common practice to “square-off’ the front of the trigger guard on combat autos to· provide a steady rest for the forefinger of the non-shooting hand. The Mossberg Combat .45 not only has a square trigger guard, but also has a small hook at the bottom front of the guard to keep the finger from sliding down as a result of motion induced by recoil during rapid fire . It’s a small thing, but that little hook really works in helping to maintain a solid two-handhold.

Not exactly today’s style, eh?

Since that list above of changes form the 1911 looks pretty long, we should point out the elements that were kept the same. Primarily it’s the operating mechanism. The Mossberg gun is a recoil-operated, short recoil system identical in principle to the 1911. As recoil pushes the slide backwards, the barrel is cammed downward at the chamber end, disengaging the two locking lugs from the top of the slide. The disassembly is identical in principle, with just changes to the details from the extra screwed-in bits. The magazines are also interchangeable, at least on some of them. Reportedly some were designed for a magazine with the mag catch cutout slightly higher than the 1911 standard, but some were also made to use stock 1911 mags. The standard, though, was just 6 rounds – a regular 1911 mag will stick out below the bottom of the grip.

Mossberg planned to release the gun to commercial public sale (they went so far as to print instructions and advertising), as well as submit them to the Army for testing in the hopes of getting a contract to replace the 1911. Somewhere along the line it all went wrong, though, because only a handful were ever actually made (and the Army apparently wasn’t interested). I had the chance to inspect gun #1127, seen a writeup on #1025 (with great photos), found an auction sale of #1105, and seen photos of #1145. That suggests that serial numbers started at 1000, and something like 150 were made in total. Why the gun died on the vine so abruptly, I do not know…it could be anything from industry intrigue to a simply underestimation of production cost and market interest.

Technical Specs

Caliber: .45 ACP

Magazine capacity: 6+1 (some can use standard 1911 magazines)

Barrel length: 4 in (102mm)

Overall length: 7.5 in (191mm)

Weight (unloaded): 36 oz (1020g)

Action: Short recoil

Locking system: Tilting barrel

Material: Stainless steel

Photos

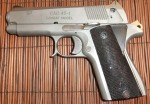

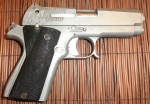

Here are some photos of CAC .45 number 1127 (thanks to reader Bob for letting me examine it). This example is missing its safety lever:

I have in my cabinet # 1171 CAC Combat Model 45-1. My father bought the pistol from a friend who couldnt get it to fire. I traded a compound bow for it with my father, put about $50 into a new hammer and it fires just fine. The only draw back I experience is the fact that after 3-4 rounds, the gun double feeds. I have had gunsmiths look into it and found that the angle of the chamber when cycling rounds is to steep. FMJ rounds work the best, as long as no more than 5 rounds are loaded into the mag. Other than that, the gun works great. I use mine for home defense, since I only have 5 rounds.

Mr. Allen,

I have CAC 45-1 # 1071. I have had it for over 25 years and could never make it run. After retiring I decided to play with it some and now it works perfectly. I am however looking for a barrel bushing. Mine is somewhat scared up. (Many disassembly/re-assembly)

Looking forward to hearing from you with any ideas.

Jack Seeley

Jack,

Do you have instructions on how to fields strip and reassemble this firearm? I recently acquired on in pieces and I cannot figure for the life of me how the firing pin is retained and how to assemble the safety. Thank you

I get a nostalgia rush just looking at it. That was the eighties alright. There was a whole cottage industry of gunsmiths who worked on 1911s. And also a handful of small companies (Devel, Detonics, etc.) that made their own and who made accessories for tricked-out .45’s. Not to mention super-duper guaranteed corrosion-resistant finishes with a plethora of brand names (Nitex, Armolloy, Perma-chrome).

Part of this was the fact that Colt and the many clone makers had such abysmal quality control then that it was considered a necessity to cough up extra to have your gun custom-tuned if you were going to get it to work consistently. As the 1911-type was still the only .45 around the major manufacturers didn’t feel the need to cater to their customers by making those special features standard. Seriously, why not have a factory craftsman take an extra half hour to do some throating and polishing and trigger testing as part of the regular manufacturing process?

ich bin stolzer besitzer einer cas 45-1 in 45acp mit serien nr. 1004

und bin in österreich austria

DEMISE: The above description is very good and The pistols are very well made. The likely demise of the CAC Combat model was I believe a combination of 2 things that I figured out after close examination of my own CAC Combat Model.

1.) The disconnector is a “Star” type sliding up and down on the right side of the frame pushing the trigger linkage bar down when the slide goes back. at the top of the disconnector was a “rivet” that the right side safety was supposed to engage pushing the disconnector down disengaging the trigger with the safety on. On my pistol the rivet was missing, so the disconnector was NOT pushed down.

2.) On my pistol the safety when engaged did not retract the firing pin sufficiently into the frame. The safety was supposed to retract the firing pin in such a way that the hammer could not reach it.

3.) The firing pin was a little to long. So with the above issues noted the pistol would fire with the safety on!

On my pistol I remedied the issue by:

1.) welding and finishing metal to the top of the disconnector for proper function, (disconnecting the trigger with the safety on)

2.) Shortening the exposed portion of the firing pin so it would be fully retracted with the safety on.

I tested the firing pin length/retraction issue first ensuring the pistol would not fire then altered the disconnector appropriately.

If other pistols were like mine (especially the length of the firing pin) this was a recipe for disaster. It could have been easily fixed prior to production.

I HIGHLY RECOMMEND ALL OF THESE PISTOLS BE CHECKED AND THE ABOVE CORRECTIONS BE APPLIED TO ENSURE SAFETY.

Also as far as I know only the magazine, magazine release and maybe the hammer would interchange with other Government Model guns making a glitch in the production of any part would shut down production.

With all that my pistol is a neat gun with lots of “custom” upgrades built in and shoots just fine.

I’ve got 3 unfinished frames for these if anyone wants a paper weight!

IAN

FYI

Iv’e got 3 Cacs at the moment #1074, 1105 and 01FD

I am planning to put them on Gunbroker in the near future

Regards,

Ron Ricci

Do you have any of your CAC 45-1’s left? I would be interested in talking to you if you do. You can call me @ 507-227-3448, or e-mail me @ steve_eernisse@hotmail.com Thank you

I have at least 50 barrels,springs and almost a dozen uppers for this pistol. An old gunsmith left them to me about a decade ago. Great for anyone who still has this sidearm. Email me for details and pics. Thank you

Bin seit kurzem Besitzer einer

CAC 45-1.

Voll Funktionstüchtig mit Sicherungshebel und 4 Magszine.

Würde mich Interessieren was sie zur Zeit Wert ist sowie mehr Info über die Waffen.

Angebote natürlich möglich.

Per Mail.

andreasaichhorn.aa4@gmail.com

for sale C.A.C. 45-1 nr. 1049