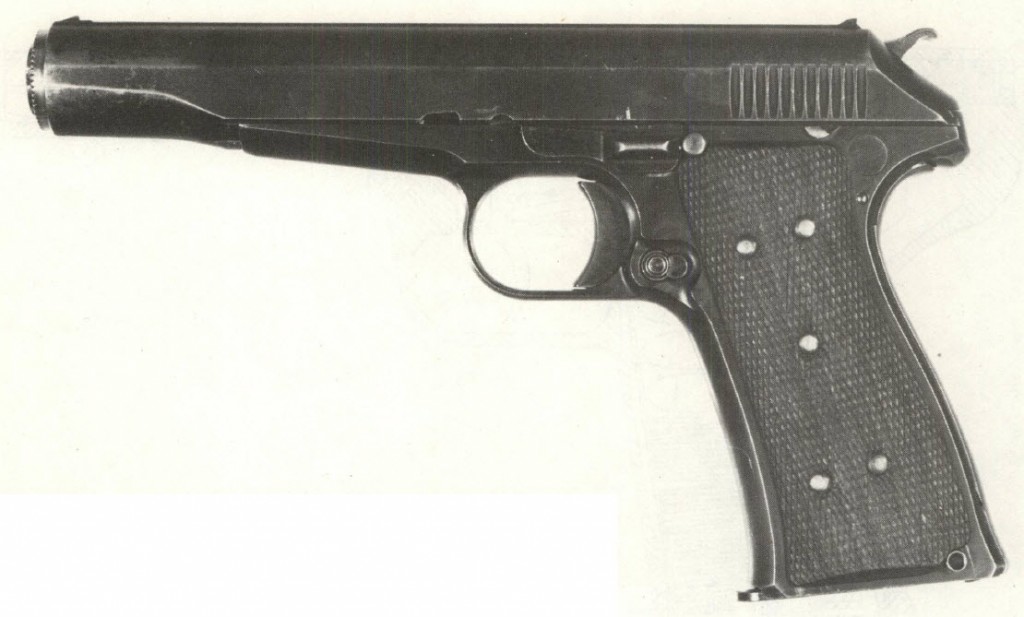

With the announcement of Remington’s reintroduction of the classic Model 51 as the new Remington R51, I have had several people ask for information on the forgotten stepchild of the Model 51, the M53. I haven’t had a chance to handle or shoot one of these myself (and may never have the chance, since only one or two still exist), so this will be more a recap of the existing information on the gun rather than a new firsthand perspective. If anyone from Remington happens to be reading this, they should absolutely consider introducing a modern .45 caliber R53 to go along with the R51! But I digress…

The M53, also sometimes known as the Remington Model 1917 (and easily confused with the several other Model 1917 firearms in US inventory), was designed by John D. Pedersen during World War I. As mentioned above, the gun was an offshoot of the Model 51 civilian pistol, and was actually produced prior to the commercial introduction of that gun. Remington was hoping for a military contract, and suggested its new Pedersen design in .45ACP to the US Army in place of the fairly newly-adopted Colt/Browning M1911. The Army responded that they would test the pistol if Remingtonwould send them one, but also placed and order for 150,000 M1911 pistol to be made by Remington. I suspect that Remington management took the position of, why bother working all the bugs out of a new design when they could clearly get large orders for an already-proven pistol in the 1911 – and the company dropped its attempts to sell Pedersen’s design to the Army.

However, on April 4th 1918 a group of Marine and Navy officers paid a visit to Remington, and indicated an interest in the M53. The Navy (and its subsidiary, the Marine Corps) was having trouble procuring enough 1911 pistols to meet its needs, and was interested in adopting its own design to avoid competing with the Army for supply. This may seem crazy by today’s standards, but it was not an uncommon situation at the time. The Navy had gone so far as to adopt its own proprietary cartridge 20 years earlier, in the .236 Lee Navy, and the inter-service rivalry for arms production was a common issue into WWII in other nations (the Type I Carcano for the Japanese Imperial Navy, the Luftwaffe FG-42, etc).

Anyway, Remington was happy to oblige and the Navy was provided an M53 pistol to test, which they did with remarkable haste.The testing took place on June 4th and 5th of 1918, and it included a 5,000-round endurance test, sand test, accuracy test, and 34 other tests or examinations. All of this was done in a competitive format, with the Grant-Hammond as the other potential new Navy pistol and the Colt 1911 as the control. We will cover the Grant-Hammond in more depth in a later article, but I will include its results for comparison here.

The Tests

The first four tests were demonstration of function and disassembly of the pistol by a Remington factory rep, for familiarization of the testing board. Tests 5-9 were counts of the number of parts, springs, and pins in each gun:

| # of parts: | Grant-Hammond | Remington M53 | Colt 1911 |

| Coil springs | 16 | 3 | 5 |

| Flat springs | — | — | 1 |

| Pins | 16 | 8 | 7 |

| General parts | 36 | 47 (27) | 35 |

| Screws | 2 | — | 4 |

The caveat there is that the Remington grip panels were permanent assemblies of 11 parts each (5 rivets, 3 studs, two stiffening plates, and a grip panel) that were not intended to be disassembled. Taking that into account, the Remington was definitely the simplest of the contenders. And as a side note, 16 coil springs in the Grant-Hammond? Jeez!

Test 10 was a detailed description of the pistols, which can be found as the “technical specs” section at the end of this article. Test 11 was whether all the parts were interchangeable between different guns (ie, no hand fitting required), which on the Remington they were. The next tests were of disassembly and reassembly time:

| Field strip | Field reassembly | Detail strip | Detail reassembly | |

| Remington M53 | 25 sec | 43 sec | 1 min 7 sec | 2 min 31 sec |

| Grant-Hammond | 20 sec | (not recorded) | 8 min 12 sec | 22 min 30 sec |

No figures were recorded for the Colt, but the M53 is clearly the winner here. Those 16 springs in the Grant-Hammond must have really taken a toll here. The Grant-Hammond required a whole selection tools for this test, while the Colt required a screwdriver and the Remington required no tools at all.

After the factory reps fired each pistol for demonstration, the testing board’s members fired the guns for accuracy:

| Grant-Hammond | Remington M53 | Colt 1911

(fired from a rest) |

|

| 25 yards, prone | 0.79″ | 2.25″ | 0.86″ |

| 25 yards, offhand | 2.95″ | 2.32″ | — |

| 50 yards, offhand | 3.80″ | 5.72″ | 1.36″ |

The board did note that the Colt and Grant-Hammond pistols were basically new, while the M53 used for this trial was pretty well worn, having seen about 6,250 rounds fired prior to the Navy trial. This accounted for its less impressive accuracy scores, and also for the slightly lower muzzle velocity it exhibited compared to the other pistols. In rapid fire, the M53 obliterated the Grant-Hammond, firing 21 rounds (3 mags) in 18 seconds compared to the G-H’s 24 rounds (3 mags) in 38 seconds.

Another test compared time to replace parts, and the M53 won this by a wide margin as well, requiring a third the time to replace the firing pin and extractor. The barrel and ejector were also subject to this test, but on the G-H those parts were built into permanent assemblies. When the extractors were removed from the guns to test them as single-shot arms, the Remington failed to eject 4 or 5 rounds, and the G-H failed on 3 of 5. However, the M53 had no trouble digesting cartridges with very thin primers (intended to be pierced for testing) nor the pair of 25% overpressure or pair of 25% underpressure cartridges. It also ran flawlessly when tested in horizontal and upside-down firing positions.

Next up for the M53 was a 5,000-round endurance test, with the factory reps allowed to clean and lubricate the guns at their digression. The Remington M53 finished this challenge with a total of 25 stoppages. Of these, 8 were failures to lock open which were attributed to a defective magazine (removed from the test after 1200 rounds). A further 14 were attributed to faulty cartridges, leaving just 3 problems with the pistol itself. There were a broken hammer at 975 rounds (not counting the 6k+ already fired through the gun previously), a piece of grip falling under the trigger and causing a failure to fire, and a corner of the slide chipping off and locking the slide open. Not bad! The Grand-Hammond suffered 89 stoppages (not counting bad ammo), for comparison. The Colt 1911, after eliminating magazine faults and bad ammo, suffered 3 broken barrel bushings.

The sand test involved plugging the barrel and inserted a loaded magazine before burying the pistols in sand. Testers were then allowed to clear sand by shaking or wiping by hand before shooting. The M53 fairly to eject once, and its slide didn’t lock open during this test, but it was otherwise satisfactory. This is particularly impressive given the board’s note that the broken corner of the slide form the endurance test allowed much more sand into the gun than would normally have been possible.

It should come as no surprise that the Navy conclusion was that the Remington M53 was “…a simple, rugged and entirely dependable weapon, which should be suitable in every respect for a service pistol” and requested a bid for 75,000 of them (which would have replaced all the 1911s and revolvers in Naval and Marine Corps service). Remington submitted the bid on June 21, 1918 (a mere 2 months after the initial interest from the Navy). That was deemed to expensive, and a second bid was submitted shortly thereafter, on July 5th, 1918. Unfortunately for Remington, the price they were hoping for was more than the Navy could justify, especially as the end of the war became more likely. The contract would have been a cost-plus basis, and Remington’s revised lower quote came to $9.93 per gun just for the tooling and profit, not including labor and materials. At this time a 1911 was costing the government about $15 – the M53 would have been significantly more expensive. As the war ended, the Navy dropped the issue, and Remington turned to tooling up for commercial production of the smaller-caliber Model 51. Only one M53 is known to remain today, in Remington’s museum. A second is believed to have gotten into private hands in 1933 or 34, and it’s fate has been unknown since at least the 60s.

The Army did test the pistol in 1920, and seems have come away with a favorable opinion, but by that time the 1911 was firmly entrenched as the military standard sidearm, and nothing more came of the M53.

The civilian Model 51 featured a concealed hammer, grip safety, thumb safety, and magazine safety. To meet military preferences, the M53 used a hammer with an exposed spur – snagging the hammer on concealment garments wasn’t a military concern, and the exposed hammer would allow manual recocking if a round failed to fire. The M53 also eliminated the thumb safety and pinned the grip safety in place, at Navy request (more on the justification for this request in a few days).

The mechanism of the M53 (and also the Model 51) was somewhat unusual, as it had to avoid infringing on Browning’s patents covering features like the single unitized slide and breechblock. Pedersen did this by devising a system in which the slide housed an independent breechblock. Then the pistol fired, the slide and breech would recoil together for a distance of approximately 2mm (1/12th of an inch), at which point the breechblock would lock against a lug in the pistol’s frame. Inertia would force the slide to continue rearward, and after a bit more travel a cammed track in the slide would lift the breechblock up and out of its locked position. The slide and breechblock would then continue the remainder of the way back, ejecting the spent case and then loading a fresh round form the magazine. This system is often misunderstood as being blowback, since the Model 51 is chambered for the .380ACP cartridge and has a fixed barrel (a feature generally associated with blowback pistols).

This mechanism actually had fewer moving parts than Browning’s 1911, had a fixed barrel for better potential accuracy, less felt recoil than the 1911, and weighed less. Had the M53 been present in the original trials for Army pistols in 1907-1910, I suspect it would have beaten out the Browning design. The Model 51 has always been an acknowledged favorite of pistol cognoscenti, and it would be fascinating to how formal US adoption could have done to evolve the M53.

Technical Specs

Action: Hesitation lock (fixed barrel)

Caliber: .45 ACP

Overall length: 8.25 in (210 mm)

Barrel length: 5 in (127 mm)

Weight (with empty magazine): 2lb 3 oz (907 g)

Magazine capacity: 7 rounds

Rifling: 1:16″ twist

References

Buffaloe, Ed. Unblinking Eye: Remington 51

Ezell, Edward C. Handguns of the World. Stackpole Books, New York, 1981.

Walker, Charles. “The Remington M53 Pistol, Cal .45, M1918, USN (almost)”. Gun Report magazine, October 1969.

I have an old M51 from 1919. I have made a few videos on my youtube page. I really like the M51 and cant wait to get my hands on an R51

Great design, very nice looking pistol!

I like how the cartridge has been elevated to the role of gas-piston!

Think of it: the first 2mm of travel, the breach-piece and slide are being pushed back by gas-pressure from the barrel, right? Gas operated!

What stops this from being blow-back is that gasses are not vented back into the action.

So is it hesitation-blowback or short-stroke gas-operated?

Cool either way!

Is Remington or the Auntie now known as Remington and owning this IP introduce this weapon into production, possibly V Engineers for staggered magazine provide a greater capacity, it would seem to be competitive offering. If of course it worked well, haha.

At the very least its engineering drawings should be available for 3d cosplay replicas – at the very least, never mind CNCing one out of steel or alloy or molding it in plastic or ceramic or laying carbon, to actually fabricate the weapon. Ian, can you include engineering, including exploded drawings, in the vid and/or links-to in the text? Tyvm N

Super info! All praise Gun Jesus, he, hickok45, and Steve1989MRE, the Holy Trinity of … something YouTube. Praise Ian, and may his Chauchat always run Wolf!