TRW was a large engineering corporation which had decided to diversify into the arms business in the 1950s. Its first major contract was production of the M14, and its success in that endeavor led the company to really dive into armament R&D. They hired on a team of quite notable arms designers, and got into many different areas of the field.

One example is a response TRW provided to an Army RFQ (Request For Quotation) in 1967, in which they propose a new general-purpose machine gun using caseless ammunition. If you have any interest in caseless ammo, you will really enjoy reading through this proposal. It identifies several types of proposed caseless cartridge and then describes in some detail the machine gun that TRW has in mind, including several solutions to the problem of obtaining a gas seal without a cartridge case. The design team included Steven Dardick, Eugene Stoner, John Foote, and Robert Sears.

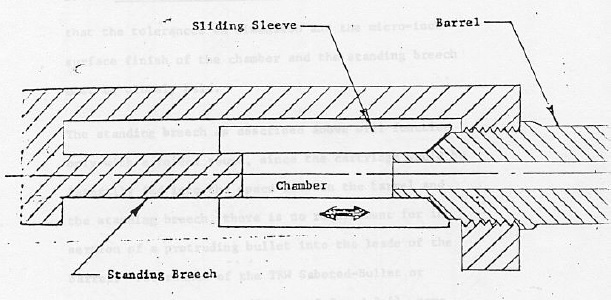

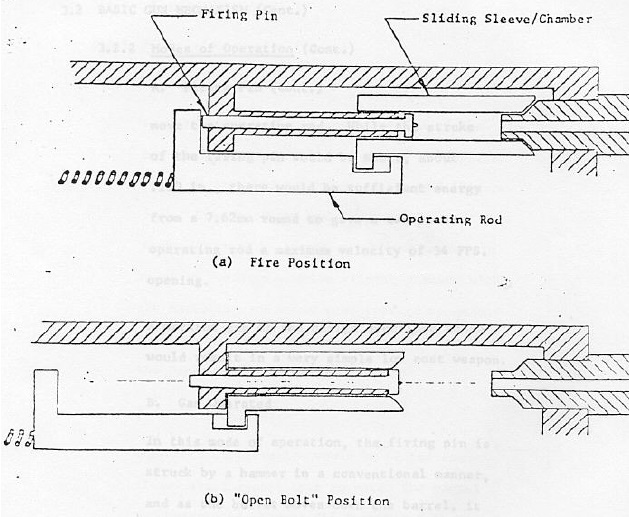

The basic idea was to use a hollow cylinder as a chamber, and have it slide forward around the cartridge. It would be supported on the back by a fixed breechblock and in the front by the end of the barrel. This sliding chamber would remove the need for a complex feeding system, as the cartridge could be kept parallel to the bore and just lifted vertically into position. It would also solve the problem of how to extract an unfired caseless round, since sliding the chamber rearward would leave the round unsupported and easy to knock out of the gun with a simple swinging ejector.

One design option laid out that jumped out at me in particular was a primer-actuated system. This same idea was kicked around by John Garand in his early prototypes, but eventually abandoned because it would require non-standard ammunition. And lo, here is is again decades later, looking like a pretty good solution:

I would encourage you to download and read the whole proposal – it’s actually quite well written despite being a technical proposal:

When I first saw this, I was thinking, was Mr. Stoner apart of this development?. He was the father of the “telescoping ammunition” design and dabbled over the year with caseless technology. After reading through the proposal, that answered my question.

Mr. Stoner consulted with TRW and co-developed the TRW 25mm Bushmaster entry. Nicely designed, beautifully built weapon. The first time I played with one and took it apart, I instantly noticed the Stoner (and even Johnson) design of the multi-lug rotating bolt. It was a 25mm, AR10!

Until the day Mr. Stoner died, he always had visions on bringing the Caseless Round to life, but often mention, even with modern technology we (the small arms industry) were years away from developing the “perfect” caseless round. Instead, he mostly focused on perfecting the telescoping round, which he pretty much did.

Thanks for posting that Ian…

ESK

I did not know that Stoner was involved with CLS but I know and remember quite well his (actually Ares’) gun he brought into ACR competition in late 80’s. This effort was terminated though even before finale so it was not tested against the rest.

It used proprietary TC ammo and it had a large drum magazine; I am not sure if the action was gas operated or not. Would be good to dig out some info on it.

Ian i think you are gonna be happy but since you talk about eugene stoner and his work at twr i found while ago the patent for the machine gun in the proposal see link below.

http://www.freepatentsonline.com/3547001.pdf

Best regards.

-Bill roger.

TRW was one of the two most sophisitcated metallurgical engineering operations in the world in the 1950’s and 1960’s. The U.S. DoD routinely went to TRW with bungled programs which TRW would rescue with aplomb. No one else could produce metallurgically difficult parts, in quantity, at a lower cost. TRW’s serious armarment programs began during WW II with the production of turbine air foils and they branched out progressively into all sorts of additiional ordnance parts. By the mid 1960’s, they began to internally develop complete small arms designs but these efforts wound down with the end of the Vietnam war. One of their last small arms efforts was the Browning BLR sporting lever action rifle. TRW developed the chain broaching process and used it to mass produce small arms parts for a fraction of the cost of previous methods.

Unfortunately, financial peculation and GM’s planned adoption of the Wankel engine devastated TRW (their main commercial product was internal combustion engine poppet valves, mostly for GM vehicles). Their gargantuan factory in Cleveland was torn down in the 1980’s and their engineering staffs were dispersed.

Very interesting approach to caseless ammunition. With the sliding chamber, instead of having to seal one end of the chamber you get two open ends.

That was actually a pretty interesting read, for a technical description. The proposed mechanism actually sounds quite feasible, but then I suppose that’s the entire point of this document. (Making it sound feasible, that is.) Sounds like developing suitable materials would be the biggest hurdle, and I didn’t see much discussion of how they were planning on overcoming the over-heating issue either. They sure did have an all-star group of engineers, though. I’m surprised how many of those names I actually recognize. Ever seen John Foote’s 3/4 scale .22 cal Mk4 Sterling pistol? Its awfully cute, only about 100 were ever manufactured, IIRC.

I’m unfamiliar with Stoner’s AR-9 Shotgun and AR-11 .22 rifle though, and Google turned up nothing. Anybody know anything about these designs?

Hiya Distal,

Got a Collector Grade’s “Black Rifle” by Stevens and Ezell? There you can find the sad story of the AR-11 aka Stoppette, which was actually a first entry by ArmaLite into the SCHV program and forebear of the later AR-15 which stepped into the gap left by the AR-11 which Ka-Boomed during testing. Actually it was a development of the AR-3 self-loading rifle, in much the same relation to it as the AR-15 was to AR-10, chambered for the .222 Rem but with 55-grs FMJBT bullet by Frank Snow from Sierra Bullets (actually this bullet was all that survived the AR-11 fiasco – it was later to become the M193). Lessons from AR-11 (designed by Doc Wilson in lieu of Stoner, who was at that time developing the AR-10 in Holland) were incorporated into Sullivan/Peck’s AR-15. Actually, there were two parallel variants of AR-11, one developed by Wilson from AR-3, and the other developed by Peck from AR-10, but only the Wilson’s project was officially christened the AR-11, while the Peck’s design was side-lined because the Army didn’t like the futuristic lines of the AR-10. After AR-11’s K-B! (the bullet struggled to fulfill the 500 meters helmet piercing requirement, so it was loaded hot enough to get better of the composite steel-lined aluminum bbl), the Peck’s rifle was analyzed and discontinued before even prototype phase because it promised equally abysmal results. At that point Jim Sullivan stepped in and together with Peck they designed the AR-15 (Stoner still being away).

And AR-9 was a self-loading 12-ga shotgun based (loosely) on AR-3, made in one prototype in 1955 and abandoned soon afterwards to step up the work on the Stoner M8 (later AR-10). It has later on returned as AR-17.

Thanks Leszek. You’re always full of helpful information.

Yeah, have the book…. did not know Stoner was out of country while working on AR-10. How he could do it in midst of ‘alien’ European culture is beyond me; hard to believe. In any case, he did experiment a lot and that is crucial in small arms development.

Anyway, here is “self-deprecating” video by AR-15 Creator himself: http://www.youtube.com/watch?v=0UAzd2-_sHE

Not very glorious!

Somewhat unsurprisingly, this looks like a better design than current caseless proposals. The USA, unlike Russia, has no mechanism in place to ensure small arms design practices are passed down from one generation to the next. This leads to a rather alarming amount of forgotten wisdom.

Having said that, I doubt caseless ammunition will ever catch on. Someone could make a good go of it, but I don’t think it offers enough advantages vs. cased ammunition of comparable sophistication to make it worth it.

Russia, to my knowledge never bothered with elaboration on CLS for small arms. It should be an indicator of potential futility of whole idea, perhaps.

@Denny,

I think Nathaniel meant instutionalized mechanism for passing down the accrued designers’ knowledge in Russia, not them designing any CLS weapons.

The idea presented is bright one, no doubt. The missing part is delivery of individual shots into chamber. I cannot imagine how the cylinder alone could separate them from feeding stack.

The feed mechanism is described in section 3.2.6 (starting on page 47).

Short version: Belt fed, with the rounds extracted sideways(!)

BTW, primer actuation predates Garand – Krnka tried it, possibly as early as 1884.

I think we’ve all had variations of this discussion before ( regarding caseless and CTA ammunition, and the weapons thereof ) elsewhere on FW.

It is interesting that John Foote’s name came up in this article ; he designed and put together a really neat, functional and straightforward 5.56mm LMG in 1969 called the Foote MG-69. It’s distinguishing feature was a forward-hinged side cover on the receiver that could be opened to entirely expose the working internal mechanism for servicing and maintenance, and also to enable the vertically-fed ammunition belt to be properly loaded.

The Foote MG-69 was more or less of the same generation as the Stoner 63, HK-13, Beretta 70/223, ROF/Enfield L86 LSW and Steyr-Mannlicher AUG LSW, all of which presaged the SAWS competition of the 1980’s that gave rise to a veritable explosion of competitive design types such as the FN Minimi, Ultimax 100, Colt CMG-1 and CMG-2, Colt M16-HB, Maremont XM-223, Philco-Ford XM-234, Ford Aerospace XM-248, Rodman Laboratories XM-235, and a Springfield Arsenal prototype that never made it beyond the pre-trial stage. Additionally, the SAWS competition gave impetus to other LMG and LGPMG designs outside of its immediate scope — the CETME 5.56mm Ameli, Beretta 70/90, Negev LMG, etc., all come to mind.

This was an presentation I saw on Autogun, it was delivered to the NDIA conference last year. It gives an interesting run down of some of the projects discussed here and touches on the LSAT program as well it also explains why caseless is simply not ready for military service any time soon.

http://www.dtic.mil/ndia/2012armaments/Wednesday13614JimSchatz.pdf

Ian, any chance of an article on the VAG73?

I do have a patent pending on a caseless ammo rapid firing system. The patent was filed by my attorney in 2011 and now it is in its final stages of approval. This is a revolutionized concept with no bolt assembly and minimal moving parts. Bolt assembly does not work with caseless ammunition because the violent movement going back and forth tears up the caseless round. The design is for a single barrel and double barrel system using in-line feeding magazine(s). The weapon is very light and has ventilation ports to minimize cook-off. Anyway, this is the first time I am writing about this weapon, if you do not hear about it in the next year and a half it means its dead.