Yesterday turned into a rather hectic afternoon, as a friend dropped off half a dozen fantastic guns that we will be out shooting tomorrow. Yesterday was my opportunity to become acquainted with how they work and prepare for shooting videos today. So instead of writing an insightful and interesting post for you, I was up to my elbows in parts. Like this:

I should say, I have not yet figured out why this pistol did not become very popular – as far as I can tell from handling, it is outstanding. It fits my hand better than most modern pistols, and the sight are almost perfectly in line with my eye when I bring it up on target. The controls are simple and modern (manual safety accessible from a firing grip, manual holdopen and slide release integrated into a single lever), the mechanism is simple (the mainspring does triple duty as recoil spring, striker spring, and extractor spring, for example), and it fires a cartridge that is adequate even by modern standards (7.63mm Mauser). And yet it seems that fewer than a thousand were ever made, and most of those were wholesaled off to Russian revolutionaries in 1905.

Lucky guy!

The story about the ‘Russian’ Schwarzlose Standard, as it was called by the factory (and not Standart), is too my knowledge unsubstantiated. The recent Rock Island Auction showed a pistol with cyrillic markings, the only example I have heard of, but these were of a regular gun trader in Kiev. Can anyone give a shred of evidence? Also, the production figures seem dubious. The highest number I have ever heard of is 510.

The Standard is indeed a beautiful gun – in fact Schwarzlose used almost the same frame for his Perfect (model 1900) toggle lock pistol.

Looking forward to seeing your report!

This particular one is of no help for production numbers – it’s #1. The story, as I understand it (and I have no hard evidence) is that the existing stock of 1898s was sold to Russians in 1905, which would imply that they were guns made for the European trade and not specially marked.

IIRC they were sold to one of the revolutionary groups and captured by Russian customs. They were then issued to border guards.

I am pretty sure I have seen Soviet 1920s manual for it somewhere on the net, but can not find it now… 🙁

Bas,

The only place I remember seeing the Schwarzlose toggle delayed blowback pistol*, was in your book “The Dutch Luger”.

I remember looking for patents for it, but don’t recall finding any.

Do you know if they ever made it into production, or was it limited to prototypes and a few individually made guns?

__________________________

* For info, it uses the same toggle arrangement as the Schwarzlose heavy machineguns

Keith,

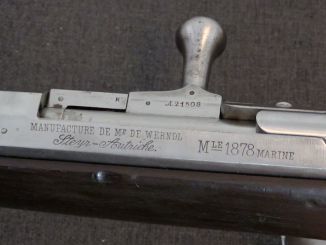

if you follow Daweo’s link to Schwarzlose patents from earlier today you will see US patent 804506 for the toogle-lock pistol, patented November 14, 1905. The original German patent is DRP 140980, patented May 22, 1901. I have seen pictures of a Schgwarzlose toggle lock pistol in a museum collection in Spain, which is the only specimen I know of. The Dutch military got a printed booklet on the pistol. I assume this means that at least some production was planned.

Bas

Thanks Bas,

I will try to check those out over the next couple of days.

Google won’t let me see Daweo’s lists in Britain (something about copyright…) and Espacenet is very slow this evening.

Look at the machining on that pistol. Beautiful, but I don’t want to think of the manufacturing cost even with modern CNC tools.

That captured my attention too.

It is testimony of state-of-art of manufacturing (machining in specific) technology and techniques of the period. As you say, CNC would make it into snap, in lieu of step by step operations which were common then.

I gather that in the top end of Swiss watch making, there is great difficulty producing the same quality with the best modern machines and full time machinists…

that a bunch of farmers working a second job in the winter, and using manual machines, achieved for the cheap mass produced factory watches, right up to the late 1970s, when digital watches replaced them.

At that point, I think most of the machines got hit with a big hammer and thrown into the scrap skip.

I doubt anyone with one of these would want to, but if anyone could make a faithful reproduction via reverse engineering, it would either be Pietta or Uberti. It might even be possible for it to be chambered in 9x19mm Parabellum and might give M1911 clones a run for their money.

Absolutely; my thinking.

Actually if you want you can see a converted one of these. I once found a schwarzlose pistol chambered in a 9mm cartridge, though I don’t know which one. It was either a 9mm mauser export or a 9mm luger.

I am very impressed with this design and consider it unique and worth of following. As a matter of fact, it inspired me to my own study which is based on it. The only major departure is in bolt to be separated into two individual pieces. It is intended for Magnum type shots, thereby not something commonly used for self-defence.

Shouldn’t this be tagged “Germany” rather than “Austria”?

AFAIK Schwarzlose was Saxon, his factory was in Berlin, and the Austrian military only tested one of his handguns, but did not purchase any.

Schwarzlose patented his design in US – Patent US712730 “RECOIL OPERATED FIREARM”, you can read this patent there: http://www.google.com/patents/US712730

You can also see other firearm-related inventions of Schwarzlose here: https://www.google.pl/search?tbo=p&tbm=pts&hl=en&q=ininventor:%22Andreas+Wilhelm+Schwarzlose%22&gws_rd=cr,ssl&ei=qgoTVfi9H8vcasXRguAN#q=ininventor:%22Andreas+Wilhelm+Schwarzlose%22&hl=en&tbm=pts&start=0

The Schwarlose Standart’s main problem was that it was hideously complex to machine, even by modern standards. It used a rotating-bolt locking system that locked into a barrel extension, operated by a fixed “stud” in the frame tracking in a cam path on the exterior of the bolt. The action was very like that of a bolt-action rifle of the Mauser type.

If this all sounds vaguely familiar, it’s probably because a nearly identical system was used on the High Standard made Grant Hammond .45 automatic later entered in the 1910 U.S. Army trials. And that half a century later, the system was revived yet again by Max Gera and Harry Sanford (both formerly of High Standard) for the original AutoMag Magnum automatics in .44 AMP, .357 AMP, and .41 JMP.

The system, as Ezell points out, can easily handle Magnum-level pressures due to its rotating-bolt lock, which is very like that of the later Weatherby bolt-action rifles (and considerably sturdier than the Newtons).

But it is never going to be cheap to make, even with modern-day CADAM technology.

cheers

eon

When Schwarzlose 1898 becomes market-available? IIRC 1902(?) I suspect that Schwarzlose design was a bit late – the Mauser C/96, Borchardt and Luger designs was available earlier, so the competition was strong.

Eon,

You beat me to the Gera and Sanford first model Automa 🙂

Unfortunately with most of the short slide designs, it is very difficult to design in a substantial enough bolt/ slide stop,

and the slide is usually comparatively light when compared to the Browning type slides, hence frequent inclusions of accelerators to buffer the recoiling barrel and recover some of its momentum to work the slide.

The effect of the light slide, is it needs to move fast to have sufficient energy to reliably complete the cycle – so it ends up hammering that slide stop even harder.

Ian, does that one have the accelerator, or a position for one?

It is pretty sleek looking for its age, especially considering some others of that era. My guess is that if it had a top, it wouldn’t be as sleek, but would keep freezing rain and mud out. While probably safe enough, the exposed bolt flying rearward towards your face in the new-fangled gadget would take some getting used to.

Slo-mo video of the bolt hitting its stops would be awesome.

I’ve always thought these were extremely handsome pistols.

The best word to describe this (and the Mannlichers) is “elegant”.

DO WANT!

One would be a perfect companion to my Auto Mag…

The 1898 wasn’t all *that* complicated compared to some D/A revolvers, the C96 Mauser, etc. Unlike those, the Schwarzlose shouldn’t have needed much in the way of select-fit or file-fit parts. And in its old-fashioned way, it’s drop-dead gorgeous, at least to my eyes.

A real masterpiece. In fact, all Schwarzlose designs, from toggle delay to blow forward action, are masterpieces and beyond the age. All consisting of small amounted but hard to make parts. Most of the 1898 parts are capable to be manufatured by MIM technology today and the frame via investment casting. The pistol works through a gap between short and long recoil action very much like Luger, since recoiling distance of barrel with locked breechbolt being nearly two centimeters, an half centimeter longer than Luger. This means, when the breechbolt begins its backward travel alone, there should be no residual gas within the barrel and the expelling force solely comes from the gained momentum. This also secures the health of bolt stopping post at rear of the frame and in fact, only its bottom section joining with the frame gets the breechbolt impact and upper ring shaped section should solely guides for striker and breechbolt. Though not seen in the dismounted parts, one of the most impotant member of main parts is, “Barrel Holder” extending through the right inner side of receiver holding the barrel in recoiled back situation against its separate return spring. At contrast to other common recoil operated locked breech pistol, this gun’s lock mechanism can not

hold the barrel in recoiled back position since barrel and breechbolt being separate parts. Most of the comments about this pistol’s limited trade success join, the inventor’s heavy effort to present his machinegun through the armies prevent its possible market chance that really deserved.

Good observations Strongarm.

The extended assembly travel to disengage lock should pay some dividends in longer part’s life. Also, holding barrel back before bolt is re-engaged is this design’s inherent peculiarity. At the same time, as you observe, it makes it part form more common modern pistols layout. Still, one mazing ‘tabanca’.

‘This also secures the health of bolt stopping post at rear of the frame and in fact, only its bottom section joining with the frame gets the breechbolt impact and upper ring shaped section should solely guides for striker and breechbolt.’

This is absolutely correct observation. In addition, the cross pin holding ‘the loop’ is ~ diameter of 10/24 bolt, tempered and press fit. Also agree that of short recoiled weapons, it’s recoil before unlock ~ 20 mm is definitely allows the gas pressure to drop more than other short recoiled ‘unlockers’.

Thanks

Thanks, good friend Denny. Especially for “Tabanca”.

Mr. McCulloch: Are you actually going to get to shoot it?

Speculations as to this gun’s commercial failure: 1) Hogg says that with the extractor connected to the striker, it was difficult to unchamber an unfired cartridge 2) The hold-open was not automatic; the lever had to be held up with the right thumb while free hand removed empty magazine and inserted reload. 3) I am recently informed that magazine capacity was 6 (six), unbelievably small for a holster semi-auto when compared to Borchardt-Luger and Mauser Broomhandle, and a payload disadvantage even compared to some revolvers of the era. 4) I would also presume a high price for the non-amortized machinery and labor, and customer recoil (heh heh) against the newfangled technology from an unproven name.

One of the auction houses sold one of these that had been converted to 9mm. Sale was two years ago and they didn’t say what flavor of 9; there were vise marks on the barrel.

What with all the .22LR replica guns being made now, it seems it might be a snap to put a simple blowback action atop a cast, molded, or stamped frame to make an artificial Schwartzlose, or C96, or Roth-Sauer or Roth-Steyr type of gun, a la the current Olympia Wolverine. What you’d miss in the fine machining you’d make up for in appearances.

An additive manufacturing technology could probably reproduce it cheaper today than a CNC machine. But that presumes a very good production run – laser is not cheap by itself.

You mean either a LASER 3D printer or an Electron Beam 3D printer using sintered (powdered metal)? The Arcam 3D printer has no moving parts like a LASER machine. It uses electrons like a way huge enormous transmitting vacuum tube, but instead of melting the plate of the vacuum tube, the electron beam is magnetically focused into powdered metal in a vacuum chamber. General Electric owns over 95% of Arcam now and is making jet engine parts with their Arcam printers. The new Colt Cobra is all MIM, except for the cylinder and the barrel sleeve. That means about 80% of that revolver is injection molded powdered metal, and it looks it too. Before GE came along Arcam was being courted by Johns Hopkins, and The Mayo Clinic as a way to print artificial hips, shoulders, knees, etc. Supposedly EB printing is not as precise as LASER, but it is over 100x faster. Whether MIM, LASER or EBM everything starts out as a powdered metal medium. With MIM the tradespeak mentions surface hardness. I am not a MIM fan at all, especially the way Colt works with MIM for the frame and barrel shroud for their New Cobra model. That gun makes Charter Arms look great. Let us suppose we do find a way to do a CNC additive process, whether it’s LASER of EBM, either one I would want some sort of a media tumbling to get a finish that does not look like someone put parking lot gravel into a sandblaster and shot blasted the parts like Colt did with the Cobra. When we consider this gun is from the 19th century the metallurgy of that day should fall well within what is possible with LASER, EBM or MIM. I’d like to see a Rockwell of at least 60, but for MIM 55 is the through hardness number and I forget what they call it. CNC machining with a 4 axis table and fixtures could make this easy to machine the old fashioned way from carbon steel blanks, and CNC controlled mills & lathes. Then one can simply heat temper the parts using modern RF induction heating rather than any old timey furnaces, and salt quenches. MIM parts like triggers and sears tend to wear out faster than machined tool steel parts. Sig Sauer’s hammer is MIM, and they run for about 30,000 rounds. A tool steel hammer & sear will run 3x longer. 3D printing is about the same. They all start with powdered metals that get shaped and then baked down to a final size and dimension. Shrinking was also common when casting parts from alloys like brass, bronze, and even base metals like iron, copper, zinc or tin. The machining on this particular gun is beautiful to me. The Gods who decide what passes and fails in the market are often controlled by tradition, misconception, and brand recognition. If that won’t kill it, politics always will.

Further to above: Ezell says this pistol was chambered for 7.65 Borchardt not 7.63 Mauser. If the action really is strong enough I don’t suppose it matters, but if there’s going to be actual shooting involved, please be especially careful. This does not take away from my opinion that this is a fascinating and even beautiful design well ahead of its era. Please also note vague resemblance to the Maxim-Silverman blowback pistol. Were the patents so publicly shared or did great minds think alike?

THANKS TO IAN’S PITCH, I own a Schwarzlose with 8+1 capacity, a Unicorn, one of the 2 I am aware of and out of ~ 30 pieces known on the web[ MOST 6+1]. This one might be A BETTER preserved one.

Here are my experiences with it. See the videos where I show a short shooting test, field strip( much easier than Ian shows) and the detailed operation of the gun with some myths clarified or corrected[ like the apparent weakness of the back of the gun, clarified multifunctional nature of it’s ~ 20 parts etc].

It is a magnificent and gracious specimen, extremely balanced and comfortable to hold and to shoot with pleasant recoil[ I used I believe, the most soft, modern 7.63- Fiocchi rounds.

Interestingly, it does not manually extract a round from the chamber due to the nature of the extractor/sear and slow speed[ but being tapered it’s easily falls out tilted back] But, it does it very robustly when shot[ leaving distinctive claw marks on the shells.

Please enjoy with me:

https://youtu.be/jOJOTT75gR4?si=JsyoCIOsvQogPJEC

https://youtu.be/IhELmRfT_Ds?si=oNmP4yBZ3vgNUikJ

https://youtu.be/dkrjsWM2Xx4?si=bxYE60hyVAzJXm6D

https://youtu.be/HHJAzn5g7v4?si=jiH1s6_KXnfKkrYi