The Colombo-Ricci is (was) an automatic revolver reportedly designed in Italy around 1910, and chambered for the standard 10.4mm Italian revolver cartridge. Very little information is available on the gun, but it seems reasonable to suspect that it was developed to compete for an Italian Army service handgun contract, as trials were going on through the first decade of the 1900s (which eventually led to the adoption of the 1910 Glisenti).

The Colombo-Ricci is distinct from other self-cocking revolvers because it actually ejected an empty case with each shot, and also had a selectable fire control system to allow either manual or automatic operation.

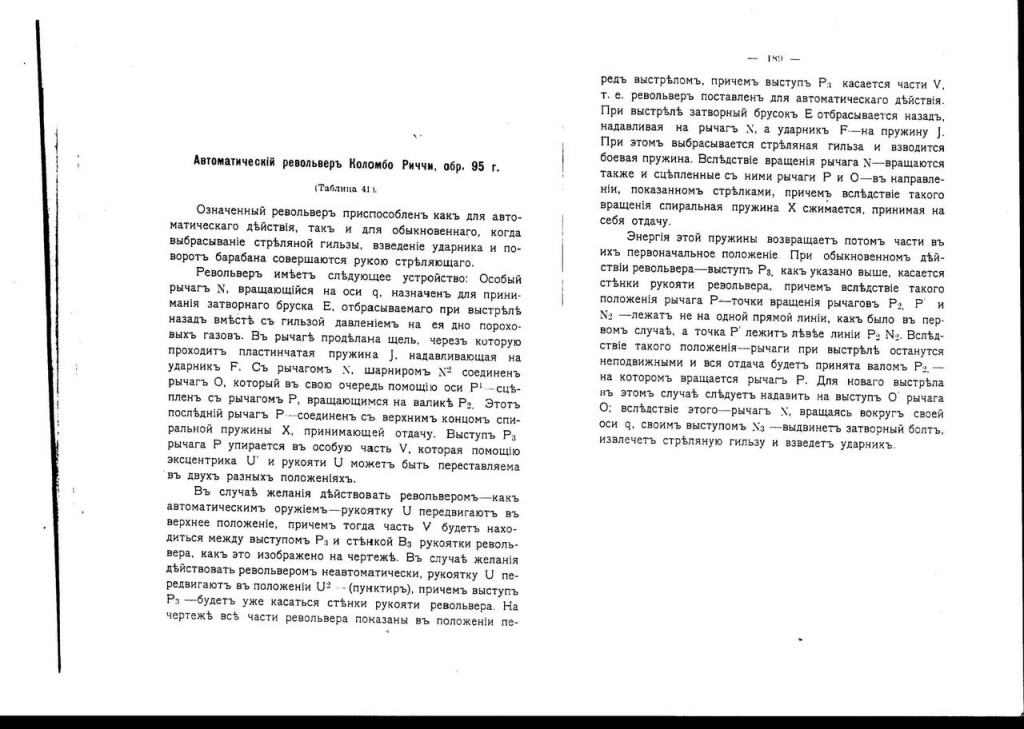

The diagram above shows the internal mechanism, and we can see how the automatic operation would have worked. The diagram was printed in a Russian book, and out friend Hrachya has thoughtfully translated the text into English, which is included in full below (along with the original Russian, for folks who can read it). Basically, the gun has 4 major operating components and two springs. The leaf spring J powers the striker to actually fire cartridges, and coil spring X is the recoil spring for the automatic system. The major parts are the bolt (E), cocking lever (O – it looks like a hammer spur, but does not actually function as a hammer), primary lever (N), and secondary lever (P). Upon firing, the bolt is thrown backwards, which pushes on the primary lever N, which in turn pushes on the cocking lever. The cocking lever is connected to the frame via the secondary lever, so that the cocking lever going backward forces the secondary lever to rotate on a pivot, and this motion is resisted by the mainspring. That spring resistance (along with a lesser amount of spring resistance from the leaf striker spring) is what controls the speed of the bolt (this is a simple blowback system).

In order to switch to manual firing, a lever on the backstrap of the grip is rotated 180 degrees (upward for automatic; downward for manual). What this does is change the pivot geometry of the secondary lever such that it is effectively locked, and the bolt cannot move backward upon firing. Think of this as a toggle or knee joint, and imagine a straight line from N2 to P2. When pivot point P is behind that line, the force of firing pushes the secondary lever backward into the frame, preventing it from moving. When P is in front of the line, the force of firing breaks the joint open, allowing it to cycle and compression the coil mainspring. What the selector lever on the grip does is move the position of P just far enough forward and backward to effect that change in geometry.

A clever detail of the mechanism is the specific location of the pin connection the primary lever (N) and cocking lever (O). It is placed such that when recoil from firing pushes the bolt back, the vector of the force exerted on the cocking lever will not move the cocking lever when in manual firing mode. However, if the cocking spur is pulled manually, the force will operate the mechanism and cycle the bolt. Compare the location of the cocking spur to that line from N2 to P2 – it is behind the line, which means that exerting force on it will operate the mechanism regardless of the geometry change induced by the firing mode selector lever. Very clever!

Unfortunately, there seems to be no record of the Colombo-Ricci actually being manufactured, and I have not seen any reference to even a single prototype surviving. It certainly would be an interesting project for a mechanically-minded gunsmith!

English translation, courtesy of Hrachya:

Colombo Ricci Automatic Revolver, mod.95y.

The revolver is adapted for both automatic and conventional (when ejection, cocking and cylinder rotation are managed by shooters head) actions.

The revolver has following construction: During firing process special lever N, which rotates on axis q, is designed to receive the bolt bar E, which is thrown back along with cartridge case by the pressure of gases on case head. The lever has a hole inside it, through which leave spring J passes and applies pressure on striker F. Lever N is attached to lever O by hinge N². Lever O uses axis P¹ to connect to lever P1, which rotates on roller P2. Lever P is also connected to the upper end of spiral spring X, which receives the recoil energy. Lever P’s lug P3 rests on the special part V, which can be set to one of two positions by cam U’ and selector U. If automatic fire is needed, then selector U must be turned to upper positions. At that moment part V will be between lug P3 and grip wall B3 as shown on drawing. If non automatic action is needed, then selector U must be turned to position U². At that position lug P3 touches the grip wall of revolver.

On the drawing all parts are on ready-to-fire position and lug P3 touches part V, meaning that revolver is set for automatic fire. When shot is made, bolt bar E travels backwards, presses on lever N , and striker F presses on spring J. At same time fired case is being ejected and mainspring – cocked. As lever N rotates it forces lever P and lever O (which are attached together) also to rotate. Direction of rotation is shown on drawing by arrows. As a result of this rotation spiral spring X compresses receiving the recoil force. The energy of expanding (back) spring drives all the parts to their initial positions.

During usual (non automatic) action of revolver, lug P3 touches grip wall and position of lever P makes pivot points of levers P2, P’ and N2 misaligned (P’ lies left to P2 N2 line). At this position levers will stay still during firing and recoil energy will be received by P2 roller (which is the rotation axis for lever P). For next shot tail O’ of lever O must be pulled. As a result lever N will rotate on it’s axis q and will pull the bolt by it’s N3 lug extracting the case and cocking the striker.

Hi I am just new here and I am intrigued by this gun. Apparently I think this one of the inspirations to bring about an auto revolver, however with a touch of a deagle. Well I am fond of manual firearms and such , also I love revolvers more than automatics because their environmentally friendly by not wasting too much lead or brass, (or steel). I think this gun is good however if you consider reliability and in the same time money this gun will fail from those portions. Also I like to point out this gun is a lot more bad ass than modern day fire arms.

How does the bolt extract the case? How can the extractor get around the rim as the bolt moves forward? Fascinating article.

It’s a blowback design, so there’s a chance it may not even have an extractor. Most simple blowback pistols can function without one, although an extractor can improve ejection reliability somewhat.