I received a request from a collector trying to find information on the Dyer International Caliber Rifle. I have been unable to find anything myself, but the fellow did have a pair of technical drawings that he shared with me, and the rifle they depict is certainly something different.

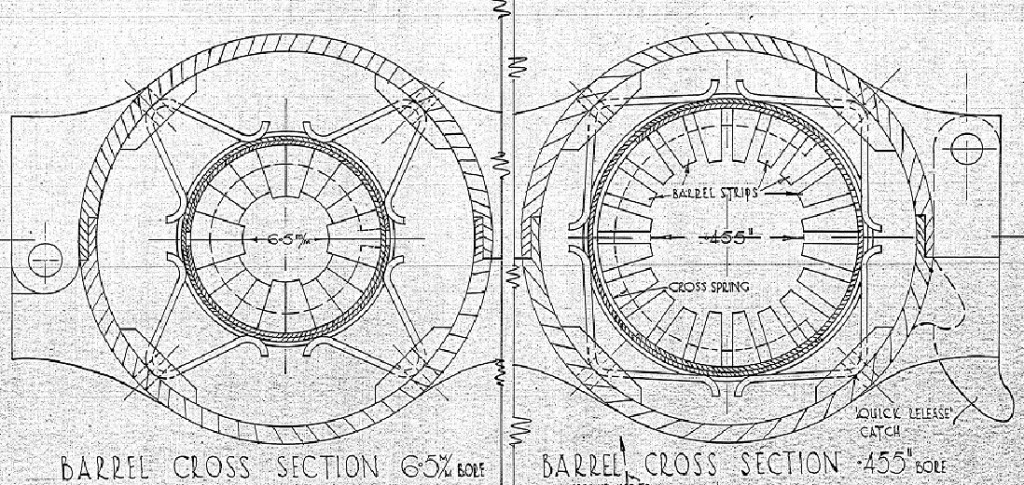

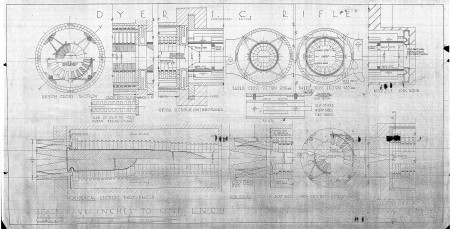

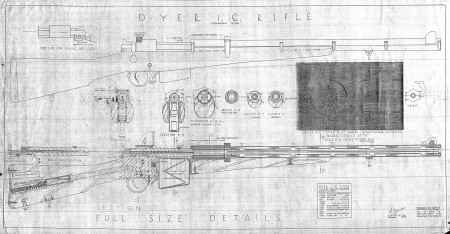

The drawings are dated December 1943, and signed by one H. Dyer – about whom I know nothing beyond his rank of Lieutenant in the Royal Engineers. The rifle he envisioned was a magazine-fed, bolt action one with the ability to chamber and fire virtually any cartridge from 6.5mm up to 15mm. This was to be accomplished by constructing the barrel from 20 individual staves or strips with truncated pyramidal cross sections. When pressed tightly together, these staves would form a 6.5mm bore, thus establishing the minimum caliber that could be used. To use a larger projectile, the clamps holding the staves would be be loosened such that the central bore they formed would be .30, or .32, or .35, or whatever diameter was desired.

The chamber was formed using a slightly different method, since it would need to accommodate varying shoulder placement and dimensions as well as diameters. Instead of having staves the full length of the barrel, the chamber area used very short ones like fingers – just a few millimeters long each. This would allow the chamber area to conform to each different cartridge case shape.

Now, there are a number of apparent problems with this design (although I do have to salute Dyer’s creativity). For example, I do not see what would prevent gases from entering the space between the staves and venting mostly around the bullet when shooting anything larger that 6.5mm. There is an expanding sleeve drawn around the outside of the staves to trap the gases within the bore, but that would not keep them from venting forward around the bullet.

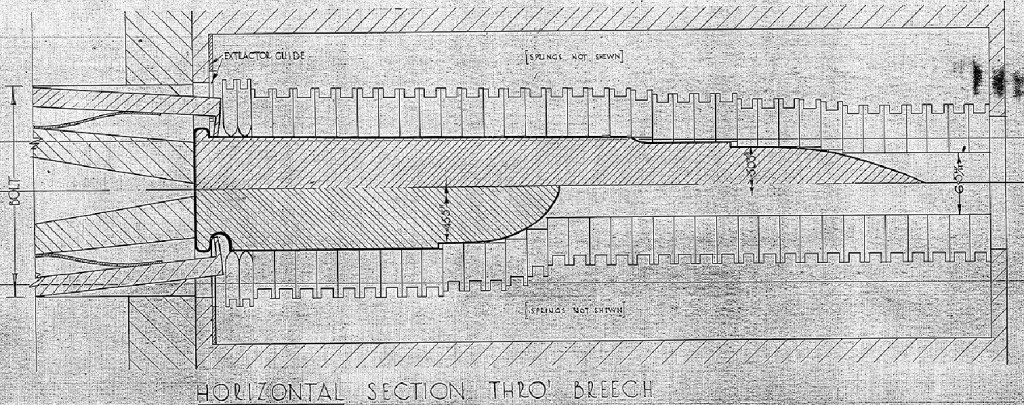

I would also question the use of a partially-supported case head (the bolt would have to be no larger than the smallest case that was to be used, so that the extractor could hook the rim of any cartridge) and the strength of the mechanism used to support the chamber fingers. The magazine would also be a challenge to design, unless one was supposed to use a different magazine for each family of cartridges.

I do like the inclusion in the buttstock of a pair of gauges to allow the shooter to ensure that the cartridge being used had neither too small a bullet nor too large a case to fit the mechanism.

Not surprisingly (given the British 1943 drawings), the bolt, furniture, sights, magazine, and trigger appear to be heavily influenced by the No4 Enfield rifle design.

If anyone knows anything about this design (especially if the technical problems were ever overcome to the extent that a prototype was made), I would love to hear it! You can see the full drawings here (click to enlarge them):

“Now, there are a number of apparent problems with this design”

What about barrel bore rifling?

You mean the rifling that would have no twist? Yeah, that’s another one.

I think twist might be arrangeable by having the staves/strips/fingers contain the twist inherently.

Though you’d still be unable to have it stabilize Every Random Bullet At Every Velocity.

That’s like the least significant problem here…

There is rifling, you can see it in the first picture, some of the staves are longer than the others.

Well, when you get the bugs worked out, apply that concept (3 times) to a Drilling! With three barrels to work with you could go from .17 HMR to 17mm. Go gopher hunting and run into a Cape Buffalo? No problem!

Now I’ve notice another drawback of this design: when using pistol/revolver cartridges like mentioned .45 Auto it would be absurd long and absurd heavy for .45 Auto and even more absurd when if you consider that it is hand-repeated – you can have M3 Grease Gun which is far shorter, far lighter, has far bigger magazine and is full-automatic.

this is why i like forgottenweapons.com , its the plase were the weirdest and most fascinating things show up

Cool design, though I feel the main use for this would be putting a bunch of light loads through it, then secretly switching it to 15mm before you handed it to a friend to try…

I suppose that was one way to appear busy and avoid getting sent to the front.

A present day Lee collet resizing die is somewhat meatier, it’s task is merely to crush a case neck onto a mandrel, not to withstand the 50K pounds a square inch plus of peak pressure from firing a round.

If the bands are tight enough to withstand firing, they’re going to be more than tight enough to:

-stop a round from getting into the chamber

-crush the case and bullet if they do get in

– hold it tight enough to ensure you’ll never get it out again

Even if you had the thing arranged like an extra long ER collet, and some sort of screw or hydraulic ram system for adjusting it, it would still have the leakage problems you point out – unless that flaw can be sold as “silencing” and the bullet dropping out of the muzzle (if it ever gets that far) in a trajectory remeniscent of an egg rolling off a kitchen work surface as – “limiting over penetration”.

For interwar and WWii era oddities, one of my favourites is Gerlich’s squeeze bore, there are even several patents for how to put gain twist rifling into a squeeze bore.

Squeeze bore, well you learn something everyday 🙂

Api Keith, how about you chamber the cartride in a separate chamber independent from the barrel and this chamber moves inside the barrel to negate some negatives?

Interesting.

You might be introducing more negatives than you cure.

David “carbine” Williams came up with “floating chamber” – he wasn’t the first ( https://www.forgottenweapons.com/clausius-model-1895/ )

What the floating chamber does is to act as a gas piston which gives enough of a rearward impulse for a cheap little .22rf round to reliably operate a full size 1911 style slide

They’re use in .22 conversions for full size pistols like the 1911.

Although allowing realistic operating drills for training, they do not have a good reputation for accuracy, and they require lots of cleaning.

Gas pistons also get hot, wherever you put them, and close fitting setups like some of the German wartime annular pistons had problems with sticking due to differential heating.

another possible use for a floating chamber would be in a blow forward design – be aware though that despite advantages in having a barrel that is a much greater proportion of the gun’s overall length, compared to a Browning style slide, Blow forwards have hideous felt recoil, and you risk blowing your fingers off cycling them (Ian has covered the Schwarzlose, the Hino Komura, and the Semmerling).

I think Clausius also came up with a barrel which was free to follow the bolt back for a short distance. This was patented again by Kimball, about half a century later, for his .30 carbine and .22 hornet blowback auto pistols,

I’m not actually sure that it does any good, unless the barrel is very light, as the inertia of the barrel is going to be almost as hard on the case head and the extractor as a fixed barrel. That wasn’t the reason for the Kimball’s failure though – the little hi-standard / colt woodsman like slides used to come flying off the back of the pistol after as few as 100 rounds (I promised Ian a write up on the Kimble – time to finish it)

The Kimble system was apparently used in the 1960s in Suomi SMGs, adapted for use as a test bed for the 9mm Lilja intermediate cartridge, It also appears to be used in the .38 special Colt Gold Cup, National Match, along with a threaded chamber to help grip the case. The colt at least does have a relatively light barrel.

Experience else where with grooves for the case to bulge into, suggest that shallow grooves rapidly become filled with fouling, and that one or two big grooves are better than many little ones from that point of view – although all trash the cases and wouldn’t be bought by those civilians who want to save cases to reload.

I am drawing a sort of Gast gun you see Keith, only I had the notion to try and incorporate Api. Now, the mechanism is based on a number of wheels with like lugs on them in a certain arrangement these are linked to each other and the barrels/bolt wheels by chain links which allow movement of each piece to happen in conjumction with the other but independently. Now, the barrels drop a certain distance with the bolts then the barrels stop and “one does the other goes forward in cycle” the bolts are attached to there wheels by chain links, so they can open further. Anyway point being, I thought instead of the barrel moving it could be a chamber which fitted into the barrels chamber the barrels being static. The firing would happen as the bolt has chambered the round, but the chamber is moving forward into the barrel. Gas would act inside the barrels chamber onto the chamber, and drive the chamber back not the barrel however this would be happening while the chambered round is moving forward. Being a separate chamber I thought .303 etc could be used, out of two Lewis gun magazines on top. I will show you a picture when I finish it Mk1 version, but in principle what do you think viable?

How much forward travel is needed to counter act the force of going back so to speak, more than an inch?

The bullet would leave the chamber before the chamber was fully chambered if you follow me so there would be a gap between the front of the chamber and the breech if you will. This would act as a sort of recoil booster, in theory. Howver would it require gas being diverted to force the moving chamber forward a sort of delay er to help push it forward as upon ignition it would be no good if it stopped going forward you see.

An “Aghast” gun, want’s to be about 1500 rpm per barrel, 3000 via twin 97 rnd pan mags. Within similar confines as two Lewis guns next to each other, purpose trench defence 200rnd bursts.

Maybe one day, Russia etc.

I don’t dislike them, but all wars are ballcocks to you or me really, but once it starts it’s abit late.

Hmmm, well it’s all good he he.

Tally ho! That is a rather splendid creation, I can’t see any problems with it whatsoever personally take that Gerry.

I had a similar notion but using nuts “you know, off bolts” the entire barrel would be a clamp in two halves with indents inside it to fit the nuts, but the “novel” bit was these would be staggered to arrange the nuts insides in a corresponding manner giving a form of hexagonal rifling.

We must have gone to the same pub, huzzah!

Oh no, nuts like off a handrail… Which I suppose aren’t really nuts, hexagonal inside allen key like, screws… Screws, hmmm changes it somewhat.

nuts?

http://3dimka.deviantart.com/art/Ice-Age-Stereogram-33692670

Quite…

As for the problem of gas escape, there was a U.S. patent issued in the 1860s for a revolver barrel with slots like the flash suppressor on an M14 or FAL running the length of the bore between the rifling lands, in the grooves(!)

The patentee claimed that this setup would reduce bore friction and thus increase velocity. Since black powder (unlike smokeless powder) generates most of its pressure right at the start instead of having a progressive burning curve, he might have been right “on principle”, but I’m pretty sure the beast would have been a holy terror to fire from the standpoint of anyone up close to either side of it. Sort of the ultimate case of muzzle-device “sideblast”. You certainly wouldn’t want to indulge in any cowboy-style “shooting from the hip” with it, and forget using such a revolver in a Bridgeport rig.

With smokeless powder, as Dyer’s design was supposed to use, I’d suspect that MV would be very low using any caliber larger than 6.5mm, if indeed you got any percentage of proper gas pressure at all. Basically, it would be the equivalent of burning the propellant powder in the open air.

cheers

eon

Ha, someone should make both and test them.

I want a fireball barrel revolver!

1860 percussion revolvers are allowed still in blightly, if you had a licence. I might consider getting one for the exitement aforesaid!

Have you not knocked up an Anderson machine carbine yet Eon old bean, I emailed a U.S company which seemed adept at making Sten replicas but they seemed reluctant to export, I stated replica.

Andrews even, Hans christian must have been thinking about bacon or butter or that camo I like…

Possibly prostitutes, Denmark is perhaps the worlds best country really beer etc, etc.

Hmm interesting concept but it just seems a bit dangerous to me… is there a possibility that over time the “barrel” could weaken and eventually change diameter while firing?

Either way this will always be my favorite interchangeable caliber design http://www.jtl.de/revolver/revolver_d.htm

What do you think about Cobray Pocket Pal? which can shoot either the .22 or .380 rounds only after the cylinder change.

I suppose the question of why, springs to mind.

Being able to fire captured ammo or something?

International caliber rifle, suppose the clues in the name.

The gas leakage problem could be mitigated by making the components with a series of interlocking lateral features. After a bit of firing, they could be so packed with fouling that shrinking to a smaller caliber would require a trip through the ultrasonic cleaner. A few years ago on another forum, someone brainstormed the idea of an “irising” barrel, trying to adapt the concept of a camera lens iris to a gun barrel. Nice try but introducing the third dimension of barrel length pretty much scotches that. I think the concept of an adjustable barrel will be woefully impractical unless we come up with some sort of expanding/shrinking metal. Like when heating or cooling only several orders of magnitude greater. I’ll not hold my breath.

As has been mentioned, the fouling issue would be a problem as with a floating chamber. They do seem to require more cleaning. When applied to a .22 rimfire application especially so since .22 ammo tends to be filthy stuff.

I’m not sure the reputation for diminished accuracy caused by the floating chamber is totally deserved. I don’t know why it would be any worse than a revolver. Indeed it should be better since maintaining concentricity with the bore would be much easier without the additional issue of timing.

I made a barrel/magazine only .22 conversion kit for the 1911 using the floating chamber concept and got just plinking grade accuracy. Not overly impressive. But, realizing that if I took those same holes and enlarged them to .45 cal, the groups weren’t half bad for a standard non-accurized 1911 and about what the gun normally produced with the .45 barrel. Really couldn’t blame the chamber. Perception was trumping reality.

I think the multi-cartridge (as opposed to multi-caliber)gun still has room for development in the vein of the .22 short/long/long rifle or .38 special/.357 mag.

“I think the multi-cartridge (as opposed to multi-caliber)gun still has room for development in the vein of the .22 short/long/long rifle or .38 special/.357 mag.”

Don’t forget the 12 gauge shotguns – in fact if we consider .38 Special and a .357 Magnum as a different cartridge then the 12 gauge 2-3/4″ and 12 gauge 3″ also must be considered as a different cartridges because they differs in overall length and pressure like .38 Spec and .357 Mag. did.

I should have elaborated more. By “in the vein of” I meant in the sense of multiple cartridges of the same bore size. For instance a gun that would digest .357, .38 spl, 9×19, 9×21, .38 super, 9mm Largo & 9mm Steyr (just because), .380/9mmK etc. Or perhaps .45 GAP,.45 ACP, .45 Colt, and .45 Win mag. Other than a slight bore diameter discrepancy one could add .45-70 to the mix. A friend once re-chambered a .45 Win mag contender pistol barrel to .45-70 and then loaded .45-70 cases with .452 dia bullets. Made for pretty entertaining recoil.

@Ownerus: something like this then? -http://www.kitsune.addr.com/Firearms/Revolvers/Medusa_Model_47.htm

Yup. The Medusa is an example of the concept as applied to a revolver. Would be interesting done as a self loading carbine.

Hi Ownerus,

The problem with most current cartridges is that they are set up for “modern” bullets, with a constant shank diameter that is smaller than the case neck diameter. You would therefore suffer quite a lot of gas blowing by, before the bullets of the shorter rounds made their way down the chamber to the throat of the rifling.

A modern exception to the bullet being smaller than the case neck, is the .22RF family, they still use “old fashioned” “heeled” bullets, where the driving band is the same diameter as the case, and a reduced diameter base (heel) of the bullet fits into the case

The large proportion of priming compound in .22rf cases ususally sets that base up, bumping it up to bore diameter on ignition

That certainly suggests that the .22rf are good candidates for this (I use .22short gallery rounds with frangible bullets in a .22lr rifle – rats hit with those little things don’t get up to run away)

all of the .22 short, long, long rifle family seem to be very sensitive to chamber and throat dimensions. Best accuracy appears to come from a chamber where the drive band is pre engaged in the throat – which is ok when you have the chambering cams of a full quarter turn bolt action or a martini, and a substantial part of the rim caught by the extractor

a martini action .22 rimfire typically grips 180 degrees of rim, a far contrast to the 5 or 10 degrees gripped by a ruger 10-22. Admittedly a blowback doesn’t need an extractor to extract when a round fires, and open bolt .22 rifles like Gevarms, often don’t have extractors

However, without chambering cams and often with puny extractors, .22 semi autos often have quite loose chambers and throating to ensure that the round chambers fully and a loaded round can be extracted easily. Although their accuracy is acceptable for most purposes, it can’t match a rifle like a Winchester Mod 52 or a BSA Martini. Bullet damage also plays a part, some .22rf repeaters take hideous slivers of lead off the bullet as they feed.

I wonder whether another way around the problem of loose chambers and multiple length bullets would be gain twist rifling, starting with zero twist? it was (is, I think there are still some in service) used in the “ADEN” revolver cannon, to avoid stripping drive bands after the projectile had made the jump out of the cylinder into the barrel – clearly seating the bullet two thou off the lands* is not an option on a gun such as the ADEN.

Loading bullets with drive bands could be a way of achieving the effect of a heeled bullet and avoiding gasses blowing by the bullet as it moves down the chamber to the rifling. Drive bands are easier to engrave (and to strip) than conventional bullets, and the main diameter of the bullet can be slightly less than the land diameter, allowing friction to be reduced, without allowing gas leakage.

Head space could be interesting, but a collet style extractor like the case holder on the old RCBS big max reloading press might be a way to hold both rimmed and rimless cases of different lengths against the striker impact.

There are some interesting discussions of bullets with drive bands over at Lutz Moeller’s site and lots more for any who can read German; http://lutzmoeller.net/English/index.php

++++++++++++++++

* The benchrest idea of having the bullets seated 2 thou off the rifling requires the case to be crush headspaced (no headspace at all) as a typical minimum headspace of 3 thou, would result in the striker shoving the bullet onto the rifling.

Extraction is going to be a bugger too,

most cases and chambers are tapered so that once a case is withdrawn a short distance, it is free of the chamber walls, a parallel sided case and chamber will need to be dragged out the whole way.

The idea of a gun that (with a range of bullet weights) will safely perform with every case from .380 rook / .38 S&W through .380 ACP and 9mmP 9×25 Mauser export to .357 max, .351 Win SL and cases made from .223 and 5.6×50 with the necks cut off or .223 blanks that got saved from the production line before they got necked or crimped (a 2.2 inch case!), certainly appeals.

Just imagine the fun that people who (like me) live in places where guns and ammunition are licensed could have with their paperwork;

“holder is licensed to purchase any 9mm, .35 or .38 ammunition…”

Hi Keith,

Your point about gas blow-by and unsupported bullets passing through the distance to the rifling is well taken. I don’t know that the gas blow by is such an issue (considering the full bullet travel leakage of a revolver)but the unsupported jump to the rifling certainly has an effect on accuracy. It doesn’t seem to be too bad in the case of the .38spl in a .357 chamber but the jump there is only about .100″ IIRC. A .380 fired in a .357 length chamber would probably not exhibit sterling accuracy.

But every design is a compromise. In the case of a small carbine intended for self defense and small/medium game hunting (which is, I think, the most useful role for a multi-caliber weapon)the longer and more powerful cartridges that might be for hunting would also presumably have better accuracy. In a self defense role at lawn and garden distances, musket grade accuracy is probably good enough.

7.92mm has a x24, 33, 57, 107 available case lengths currently apparently. So perhaps you could make a chamber function in a similar manner to the Dyer to accomodate the different case widths, and have it telescope around the barrel for the various lengths or something.

If the cases were the same width but different lengths, in the same cal. I think this is what they describe as “modular” pistol, carbine, rifle sort of lark.

“Irising” in the manner of a chuck, is it on a drill, the bit you put bits.

I’m trying to figure out exactly how the bolt locks. Looking at the diagrams of the bolt head, I at first thought it used a Stange type flap-locking system similar to the Colt-Sauer bolt-action of the early 1970s, then I realized I was actually looking at the dual extractors.

I’m thinking it must have been intended as a rear-locking system like the SMLE, as that bolt head arrangement wouldn’t lend itself to a Mauser-type front-end lockup. That would tend to explain the huge Model 1917 Enfield-like receiver bridge as well (yes, I know the M17 was a Mauser-type front-lock).

In any case, I suspect Dyer may have seen this widget as a “progressive development” of the SMLE, or at least as a special mission weapon built on the SMLE action, rather like the DeLisle suppressed .45 ACP carbine. For SOE, etc., it would have the advantage of being able to fire almost any ammunition that came to hand. Even 20 or 28 gauge shotgun rounds, for that matter. They were fairly common in Europe pre-war, along with the peculiar French 9mm rimfire “garden” shotgun type.

The chances of actually hitting anything with any ammunition in it, OTOH, would probably make a Brown Bess musket at 100 meters look like a Sedgely Springfield by comparison.

cheers

eon

“special mission weapon”

It is too big to fit this role – it is too long hence unwieldy, so don’t fit missions where the speed is crucial/can’t be hidden under plain cloth.

Also it is not good suited for parachutists – even shorter weapons as a M1 Carbine get their dedicated “para-version” – the M1A1 Carbine with folding stock. Soviet parachutist use DT (tank) machine gun in lieu of DP (infantry) machine gun – because the DT was shorter (moveable stock against fixed stock of DP).

As W.h.B. Smith said of the U.S. Navy (Seabee?) .38 “Glove Gun”, “Such inane devices crop up in every wartime period.”

The fabled “centrifugal machine gun” (a flywheel powered by an electric motor or gasoline engine that launches steel ball-bearings at a high ROF)is just one example of an evergreen gadget. I’ve seen magazine articles on such with titles like “Gasoline Gun Whirls Death” going back to the 1930s. (That one is reprinted in Wasn’t The Future Wonderful by Tim Onosko);

http://www.amazon.com/Wasnt-Future-Wonderful-Trends-Technology/dp/0525475516

In Grenades & Mortars (Ballantine, 1974), Ian Hogg describes the German and Austrian compressed-air and acetylene-powered mortars of WW1, as well as the widget reportedly designed in 1940 by an ex-Skoda Works designer who escaped to England (p.117). It was a “multi-caliber” mortar that according to the designer could fire British 2 inch mortar bombs, German 5cm mortar bombs, No. 36M hand grenades, and any sort of spigot bomb (I assume he meant the ones used with the Blacker Bombard, and possibly the PIAT).

Hogg could never find a diagram or description of the beastie, but on p. 95 of his book there’s a WW1 photo of a Belgian mortar that I suspect may have been built on the same general principle as this gent’s concoction.

cheers

eon

The centrifugal gun is the evil weapon deployed by the local council highways dept each winter to assault the paintwork on my vehicle.

In a more vigorous form the same principle is used for shot blasting and for reducing hard abrasive gravel to sand, in a vertical shaft impact crusher.

Gasoline powered mortars could be quite effective, especially if extra oxidizer is provided. There are vids up on youtube of kids achieving a couple hundred meters with hairspray and uncompressed air charges in spud guns. The projectile isn’t necessarily limited to spuds, some seem to use aerosol cans and drinks bottles with good range.

I don’t have any details about the “mortars” used by the protestors in Kiev a few weeks back. Supposedly they were compressed gas powered, and seem to have been quite effective at launching molotov cocktails, which in turn seem to have been very effective against the JBT’s armoured personnel carriers.

It seems that the hard core in the protest were middle aged, battle hardened veterans of the Soviet Afghan campaign, far braver and more determined under fire than any in the fat blue line that was deployed against them.

Alternatively the gun powder engine, gun powder being the petrol to power a horseless cart thought of by some European chap with a big wig in the 17th c apparently.

Maybe the idea was to allow a rifle to fire normal rounds then say Boys type/purpose rounds, simply to avoid having to carry a Boys and a rifle before they thought of the Piat. I suppose it depends if it wasn’t much bigger/heavier than a no.4 to start with, I presume the magazine is only for similar sized rounds other ones were to be loaded individually.

What’s that spring thing in the stock, do Enfields have them out of interest? I don’t actually know how a smle locks, have to find out.

The bolt has a long lug running down it’s length, which sits behind some static part at the rear when you fold it right?

It has two rear lugs on the bolt with the locking seats cut at a helix angle to compensate for the threaded bolt head.

The right lug extends forward to form a bolt guide

I Watched a videos on them, like it.

Incidentally eon, the picture which appears to be as if you were looking towards the butt from the mag well. Is a reasonable illustration of the square to diamond lark I once alluded to, if you look at the square sort of section around the circular bolt now imagnine the for gaps at “corner” of the bolt in the square were attached to the bolt, the tube runs inside the square but if you turned the bolt the square on the bolt ie. Via the gaps being attached to it, would not fit into the square behind being a diamond now.

Very clever, but it seems like a solution in search of a problem to me.

This is a not-so-great solution to a “logistical hassles” problem where British troops in the field might have 10 “standard-sized” (I don’t know the real size of the ammunition crates) boxes of British 303, 50 boxes of American 30-06 along with scavenged M1 rifles, and perhaps a ludicrously large supply of captured 8 x 57 IS and several K98’s while waiting for a supply truck that carries British 303. If the aforementioned logistical nightmare was what the inventor wished to dispel, he could have done something else… If you’re out of ammo, why not just steal a dead enemy’s main weapon rather than have a ludicrously expensive and impractically constructed rifle that can be adjusted to fire any round at the cost of the barrel’s structural integrity?

The Tommies already had a solution to two-thirds of that problem; it was called the Bren. Inglis in Canada made them in both 0.303in for Commonwealth forces, and 7.9×57 for the Nationalist Chinese.

“Conversion” consisted of changing out the bolt (with a rimless vs. rimmed extractor), changing the barrel, and swapping magazines. Later on in its career, the L4 version was converted to 7.62×51 NATO the same way; British Paras were still using them in the Falklands in ’82, and I suspect at least a few are still hanging about in the armories today.

Inglis would only have needed to bore a few barrels to make it available in U.S. .30-06. The 7.9 bolt would work well enough. As for magazines, those would probably have to be made, although the 0.303in mag would probably work with .30-06 if you only loaded 25 to 28 rounds. I think the 7.9 magazine is a bit too short front-to-back for the ’06’s loaded round OAL.

For real fun, get a Norwegian BAR in 6.5×55 Mauser or an FN made Model 30 aka Model D in 6.5, 7.65, 7.9 or .30-06. The latter would have been a perfect “rifle” for Indiana Jones, who kept violating Keith’s Third Law (Never bring a pistol to a rifle fight). 😉

No matter where you went back then with a Model 30, with the right spare bits in your kit you’d be able to find some ammunition that would fit it.

cheers

eon

Im confident this desing never made it beyond drawing board.

I am surprised no one has mentioned the Phillips & Rodgers Medusa Model 47. It is able to fire and extract 25 different cartridges in the .38/9mm/.357 ammunition range.

Popular Mechanics article: http://www.popularmechanics.com/outdoors/survival/gear/1277301

Thread on AR15.com: https://www.ar15.com/archive/topic.html?b=10&f=17&t=615218

According to the videos below, .32 ACP and .30 Carbine can also chamber.

Video Review: http://www.youtube.com/watch?v=fkY_5Nz649s

Shooting: http://www.youtube.com/watch?v=s49-iKC7_pA

Years ago, George Nonte made up several “multi-caliber” 1911A1 Colts, by using a standard .45 plus a .38 Super slide and barrel, a 9x19mm barrel, a 10mm barrel, and a .45 barrel relined to 7.62x25mm Tokarev, plus a .22 Conversion Unit. The .38 Super barrel would of course also handle 9x23mm Largo and 9mm Steyr. (9×22.9mm- one of those “differences which don’t amount to much” situations, as most lots of ammunition will have variances in case OAL of at least that much.)Plus appropriate recoil springs of different strength, and magazines.

He even managed to get it to work with .380 ACP in the 9x19mm barrel with a lightened .38 Special Gold Cup recoil spring. (Llama of course made the III-A .380 with a locked breech, about the only such .380 I know of unless you count the old Frommer long-recoil “Stop” from before WW1.) And yes, just for hilarity’s sake, he added a .38 Mid-Range Wadcutter barrel and magazine to the set.

Final score; .45 ACP, .38 Super, 9×19, 9×23, 9×22.9, 10mm, .380, 7.62×25, .38 Special MRWC, and .22LR in one small valise.

H&K had their pocket auto with barrels and springs in 9×17, 7.65×17, 6.35mm, and .22LR, but I don’t think anyone else ever took it as far as Nonte did.

BTW, during the great MilSurp influx of the Nineties, some surplus Chinese Army 1911s showed up in the U.S., courtesy of Norinco. Most were still .45s, but about a fifth were rebarreled etc. to 7.62x25mm. IIRC, most were either Remington-Rand or Ithaca made, like more than half of all U.S.-issue 1911s during WW2.

cheers

eon

The revolver design is more friendly for multi-caliber than the automatic pistol, simple because the revolver are not vulnerable on powder charge (unless the too big charge will use, causing the gun blow). If the cartridge will headspace properly and the maximum pressure will be not exceeded then the revolver should work. I’ve heard that the members of Resistance has load the .45 ACP (air-dropped with Liberator pistol) in the old MAS 1873 Chamelot-Delvigne revolvers – and its work, however I don’t recommend to follow this practice.

They used to use an awl or knife-point and a hammer to peen out little “tabs” on the rim of 9x19mm rounds to use them in 0.380in S&W M&P, Enfield, and Webley MK IV revolvers, too. As Jan Stevenson says when referring to the practice in Pistols, Revolvers, and Ammunition (Crown, 1972), this isn’t the kind of stunt you’d want to try in peacetime.

He further relates that due to French gun laws, recreational shooters tried all sorts of less-than-politic combinations, like .32-20 WCF in the 8mm M1892 revolver or the .45 ACP in the M1873 as used by the Resistance. Stevenson calls this “roughly analogous calibers but with a 100% discrepancy in chamber pressure- the wrong way!” He also says that some shot the 8-92 in .38 special revolvers, with rather spectacular visual FX as the smaller 8mm case came apart in shreds in the .38 chamber.

When those M&Ps in .380 came back Stateside in the Fifties, several surplus dealers ran .38 Special chambering reamers into them to sell them as “converted to .38 Special”. The cases would bulge at the rear due to the greater base diameter of the rear half of the chamber, but with factory rounds they rarely split.

One peculiar side effect of this was that a .38 Victory model modified like this would also chamber and fire such odd rounds as .38 Super Auto. In fact, on 22 Nov 1963, when Lee Oswald shot Officer Tippet while attempting to evade arrest, his mail-ordered .38 Victory was loaded with both .38 Special and .38 Super rounds. He shot Tippet with a .38 Special.

If he’d fired a .38 Super, it could very well have exploded right in his face.

cheers

eon

You reminded me of this: http://youtu.be/HIoRFJQ2m90?t=2m40s

The link goes straight to the good part. I have to admit I had no idea that there is that level of interchangeability between those circa .45 caliber straight-wall cartridges, including rifle cartridges.

EW;

People forget (or more often don’t know in the first place) that the .444 Marlin case is basically a “stretched” .44 Remington Magnum case, which means just a super-long .44 Russian/.44 Special case- smaller in diameter than a .45 case.

The .44 cases would always go into a .45 Colt chamber due to being smaller in diameter, which was no big deal with the Russian or Special (pre-1955). But once the Magnum arrived, a .44 accidentally dropped into the chamber of a nice “blackpowder frame” 1873 Colt could turn it into an impromptu frag grenade right in your hand.

I’d noted the various “survivor/trapper” .410s over the years that were also advertised as using .45 Colt, and it doesn’t surprise me that .444 Marlin will go in one, as well. And no, it’s not a good idea.

Going back to Stevenson, he mentions that a lot of cheap .38 Special revolvers made before about 1970, especially foreign-made ones (usually S&W M10 knockoffs) have chambers which are bored “straight through” with no chambering shoulder. This means that as long as the cylinder is long enough that the bullet does not protrude from the front, .357 Magnum rounds will chamber and the revolver will function. And promptly and enthusiastically blow up on the first shot, most likely. Similarly, a lot of the early “Peacemaker” copies made in Europe in the Fifties and Sixties in .44 Special also have “straight-through” cylinders, so yes, .44 Magnums will “fit”, and no, it’s not safe to pull the trigger on one.

Oh, and P.S.; While 9x23mm Winchester pistol rounds will certainly chamber in a 9x23mm Bergmann-Bayard (Largo) chambered auto, that’s also the equivalent of a .357 in a .38. Don’t try it.

I wish Winchester and Colt had made their “9mm Special” round a 9x24mm, then we’d only have to worry about the odd 9x25mm Mauser Export-chambered Broomhandle here and there. Which could probably take the pressure, as the old 9×25 was a Magnum-level load by anybody’s reckoning. 125gr @ 1,350 FPS for 506 FPE is .357 Magnum performance, and would definitely generate pressures in the .357 range, too.

cheers

eon

What is interesting one of the first commercially successful automatic pistol cartridge – the .32 Auto can be chambered in .32 S&W Long revolver and in some .32 S&W if the chambers are long enough. If the .32 S&W Long is a solid firearm (not cheap knock-off) nothing bad to user will occur – accuracy may be inferior to proper ammo, but it don’t apply to .32 S&W especially if it was designed to black-powder only.

The straight-chamber also cause that Colt 1892 designed to .38 Long Colt can be loaded with .357 Magnum, which is obviously not good idea.

9x25mm Mauser Export was used in Hungarian Danuvia 39M (and subsequent) sub-machine gun. I don’t know any other military firearm utilizing this round.

I think it was a turn of the century Gasser revolver in 8mm which is identical, even in pressures to the .32 H&R Mag.

I’ve seen .380 acp negligently put through a Browning Hi Power. They fed, and fired (I’m not sure whether they headspaced on the semi rim or just on the extractor), occasionally cycling the slide, but the case heads bulged badly into the feed ramp.

I think some of the Steyr Solothurn smgs were also chambered in 9x25mm Mauser Export.

Daweo;

Going the other way, the .32 S&W (short version)won’t feed through the magazines of most .32 autos, but it can be fired and will eject from most if just hand-fed into the chamber. Some people have in the past filed the rim down and filed an extractor groove into the .32 revolver round case so it will feed and fire normally. According to Stevenson, a “field mod” like this figured in the Petrou/Zemenideies murder case in London (1933). (It might be noted that Petrou was found “not guilty” at the Old Bailey due to a cast-iron alibi, and the identity of the actual killer is apparently still not known.)

A less extreme “mod” apparently was used by the U.S. Cavalry in the 1880s. Sometimes when perusing collections of Old West relics, you might run across a .45 Colt cartridge with the bullet cut off flat about 1/8″ ahead of the case mouth, which reduces bullet weight from 255 grains to about 170. Some have claimed this was an attempt to increase the killing power of the .45 round, by increasing velocity and giving it a flat-nosed bullet profile for increased wounding effect.

What it actually was, was usually the result of Army Quartermaster’s fouling up. At the time, the U.s. Army had two standard revolvers issued to cavalry units; the Colt Model 1873 .45 Colt, and the Smith & Wesson Model 1875 “Schofield” Model top-break, also a .45.

But the .45 S&W round was shorter-cased, due to the S&W’s shorter cylinder. While the .45 S&W round worked perfectly well in the Colt’s longer cylinder, the .45 Colt round could not be used in the S&W. While the S&W chambers were bored “straight through” with no chambering shoulder, the .45 Colt round was long enough that when chambered, part of the bullet nose protruded from the front of the cylinder, making it impossible to rotate same.

Unless, of course, a clever “yellowleg” took out his sheath knife and cut the nose off the Colt round’s bullet. Easily enough done due to the bullets mostly being pure, soft lead back then.

I’m sure civilian Schofield owners had to do this on occasion as well, as not every store on the frontier had .45 S&W, but practically everybody stocked .45 Colt along with .44-40 WCF. But I’m also fairly sure that most such “conversions” were the result of a Schofield-armed cavalry troop at a frontier outpost opening crates of revolver rounds, to find that some simple son-of-a-sea-cook in Supply got the requisition wrong- again.

cheers

eon

Guns and Ammo magazine* did a piece about 1981 or 82 with a single 1911 receiver, and:

.45ACP and .38/45 Bo Clerke just changing barrel

9mmp and .38 super (I think that needed a commander slide to get the correct ejector slot position allong with the 9mm extractor and breech cut out – barrel changes were required for the two rounds.

a couple of .22 conversions.

I can’t remember whether they were able to use the .38 Spcl Gold Cup barrel, slide and mag, or whether that would havbe required some mods to the receiver.

===================

* back in the days when it occasionally had something interesting to say – or when I was young and naive enough to think it did.

We think alike. I gave up subscribing to G&A and the other Petersen magazines, when it became obvious that their writers had no interest in any sidearm but the 1911, and no interest in any rifle but the AR-15.

They’re certainly good, but there are also a lot of other one out there.

I was mainly interested in their articles on antique and historic weapons, in case you couldn’t guess from my posts here. ;-).

cheers

eon

I have one copy here with no cover from September 1998, so I can read you an excepert from the journal of one Bart Skelton who is a Western Lawman “some sort of Cowboy, Wyatt Earp type presumably for readers from the realm of her Britanic majesty” Anyway if any of our former colonial chums live near New Mexico, a chap named Lilley stashed a 30-30 Winchester somewere in or around Laney place, lake valley, Gila county prior to WW1 and he forgot were so it’s still there probably. So if you fancy a day out, mind you he seemed fond of wrestling bears and annoying snakes etc so it might be a hostile enviroment. Bart says consult “the Ben Lilly legend, by a J frank dobie” this book will tell you more.

This fellow has his own Wiki page now,

http://en.m.wikipedia.org/wiki/Ben_Lilly

In the internet age, 16 years later.

Better late than never.

In the panel on the drawing, which I think states what caliber it can take it say’s .25 to .455 I think. You can make out masden Demark…

It’s to do with having a rifle which can shoot pistol cartridges, of types listed or inbetween so long as the bullet isn’t less than .25 or greater than .455 which would perhaps infer it was about captured ammo maybe a partisan rifle.

6.5x55mm and .455 Webley have a base diameter of .480 apparently

Code for 8mm German, good design I like it.

It will fire all appropriate military rounds pistol/rifle of the time, with deeper rifling I think so it has limitations in regards this that and the other, but it would kill when pointed at an enemy withing these.

Better than a stick, with the plus they could be killed by their own bullets.

Perhaps even sections of, it would impart some spin as does the paradox rifle.

Maybe the Liberator idea won, kill them with a gun “of a sort” and steal their gun, gun.

The “Liberator” logic was behind about half the improvised guns used in the Philippines from the Insurrection on. So what if it was just a piece of pipe with home-made black powder, a ball-bearing for a slug, and set off by applying a lit cigarette to a touch-hole?

It only had to work once, and the Resistance had a nice, shiny new rifle and its accoutrements to add to its inventory. And the enemy was short one man.

If the “hand cannon” was still operational and could be passed on to somebody else to repeat the procedure, that was a bonus. It had already “paid for itself”.

Guerrilla Economics 101.

😉

cheers

eon