We’re privileged today to have another guest article written by Leszek Erenfeicht (and I would strongly recommend that our Polish readers check out Strzal, the print magazine he regularly publishes in). This time he is discussing the most widely produced submachine gun made by the Polish Underground – the Blyskawica. It’s a fascinating story of desperation and ingenuity, and a gun that we normally only see a few grainy wartime photos of. Thanks, Leszek!

Błyskawica: Poland’s First Successful SMG

by Leszek Erenfeicht

The Błyskawica (Polish for ‘Lightning’, pronounce bwiskavitsa, with ‘wi’ to be read like in ‘wisdom’) was designed and manufactured fully clandestine, for the Home Army (Armia Krajowa, AK), mainstream Polish underground movement during the German occupation of Poland during the WWII. It was the first Polish-designed submachine gun ever to be really mass-produced – and that under the most difficult conditions imaginable.

Compared with their French counterparts, enjoying generous airdrops from Britain, just a short hop over the English Channel away, Polish resistance fighters were poorly armed, indeed. Airdropped weapons were scarce and scant prior to fall of 1943, when airfields captured in Italy enabled a – slight at best, by the French standards – surge in the airdropping campaign. Submachine guns were virtually non-existent in Poland prior to the war, were only used by the State Police (with little over 100 Suomis and 50 M1921 Thompsons). The Home Army was created as early as October 1939, then called the Union For Armed Struggle, with the aim of preparation for the general national uprising to win the independence in front of the hopefully steamrolling Allied (French and British) troops, rather than idly waiting for them to come and liberate Poland. The submachine gun soon proved to be a very useful guerrilla weapon, and with an agenda like that, the AK simply had to find some source of SMGs supply more dependable than black market and incidental disarming of German patrols, usually provoking bloody retributions.

Let’s Roll Our Own

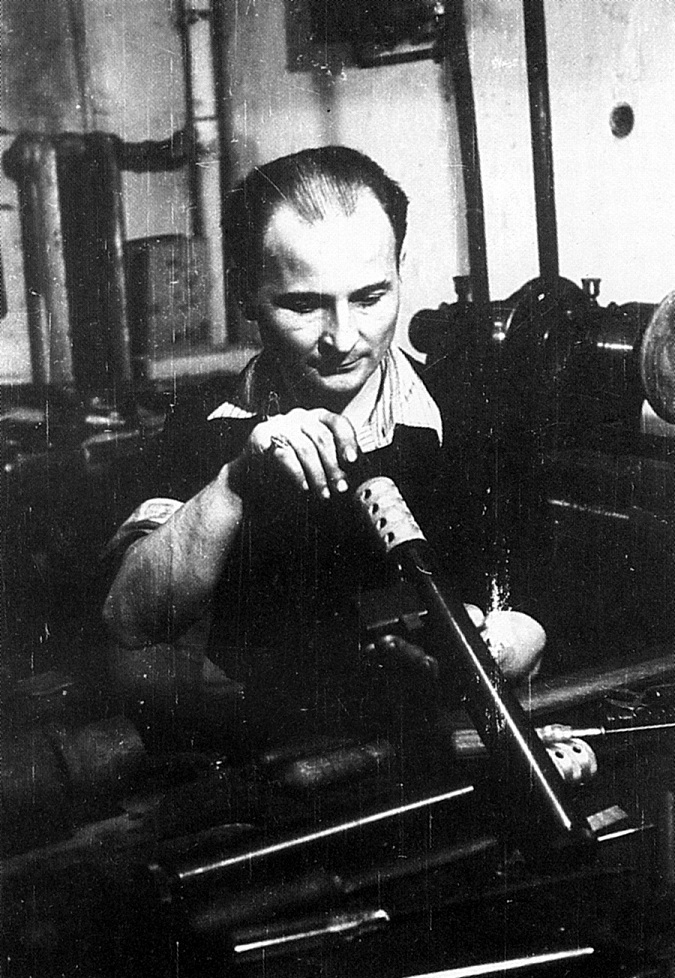

In September 1942, Wacław Zawrotny and Seweryn Wielanier, two mechanical engineers with no prior small arms designing experience, proposed to the Home Army’s Warsaw Area Command an idea of designing and manufacturing a 9 mm submachine gun of their own. They’ve studied the most modern foreign models, the MP 40 and the Sten, and found both unsuitable for straightforward copying. Although the Sten was simple enough to be manufactured under the most difficult conditions (later on to be confirmed by conservatively estimated 2000 Sten copies and look-alikes made throughout Poland during the war), it was deemed awkward to handle and hardly concealable with its fixed stock and side-sticking magazine. On the other hand, the MP-40 handled like a dream, and was highly concealable with the stock folded, but the manufacturing technology (with extensive use of die-forging and spot-welding methods) was far too complicated to replicate with what little machinery and tools were available for the job.

Both gentlemen agreed that the new submachine gun should combine the best features of both, while keeping the manufacturing technology as low-tech as possible. They decided to employ plumbing micro-groove threads and machine screws for most of the joints – bayonet couplings and spring latches of the factory-made weapons were far too complicated for manufacturing with the available hardware.

Gradually, by April 1943 the Błyskawica took shape and prototype drawings were being prepared. After the design work was done, the time has come to find subcontractors and organize an underground manufacturing network, supplying the parts for the clandestine assembly shop. In harsh conditions of the German-occupied Warsaw, with tight control over all machine shops activity, shortages and rationing of the cutting tools, with suitable materials put on the ‘restricted supplies’ list and sold only to the holders of permits from German administration, this was a very hard task, indeed. Nevertheless, bribing and stealing their way, working in the Wielanier’s private flat, by early September 1943 they managed to manufacture and assemble the first working model minus barrel and magazine – which they chose to borrow from a British Sten to overcome the narrowest of production bottlenecks.

Official Acceptance

The gun was submitted for approval to the Home Army Ordnance Command, for test-firing in the woods around Warsaw’s suburb of Zielonka, and approval. Formal acceptance into the inventory of the clandestine army meant – among others – that the designers would be refunded their private money spent so far on the gun. The acceptance test was the first occasion for the Błyskawica to really shoot, after a borrowed Sten barrel and magazine were installed – so problems were inevitable. At first the prototype refused to fire at all, then suffered numerous malfunctions, but Wielanier was able to rectify the situation with what simple tools were available at hand – and gradually the jams ceased. Finally the gun fired a whole magazine-full in a single burst, and the project was green-lighted.

The Home Army HQ Diversion Directorate’s commander, Colonel Emil ‘Nil’ Fieldorf, a brave and intelligent man, pre-war career officer, parachuted to Poland as early as 1940, was briefed of the new invention and demanded an additional live-firing demonstration. This was held in the most daring – if a little cavalier – way. At high noon on September 27, 1943, right on the painful fourth anniversary of the Polish capital’s surrender in 1939, right smack in the downtown of the enemy-occupied city, a party of three raincoat-clad men stepped out to the center of the crowded Theatrical Square, in front of the Warsaw City Hall. One of them reached under his coat, raised a prototype submachine gun and performed a classical ‘magazine dump’ into the air, to the delight of the cheering crowds around and to the horror of the two bodyguards, flanking the Colonel – who was as happy as a child on a Christmas morning!

After going through all the trials with flying colors, the gun was accepted for serial manufacture, which meant that the designers had to assemble a complete set of drawings for the gun. These were ready in October, and while en route to deliver the briefcase full of transparencies to the Home Army Ordnance Command, Mr. Zawodny only hardly avoided being arrested in one of the frequent German Security Police ‘combing’ raids, when a section of the street was cordoned-off, and all people rounded-up and trucked away to be later sorted out by the Gestapo. Most of people caught up in these manhunts were then deported to Auschwitz even if they weren’t suspected of anything – just to spread terror to the others. One can only imagine what horrors would unfold, if he get caught with a briefcase full of clandestine submachine gun blueprints!

The name Błyskawica came from the three lightning bolts carved in the aluminum butt-plate. These were added to prevent slipping of the plate but also served as a camouflage – the butt-plate’s drawings were labeled ‘electric oven handles’ and the three lightning bolts were a trademark of the popular Electrite brand. The name was made official in November, when a first pilot batch of five, complete with air-dropped Sten barrels and magazines, was duly accepted by the Ordnance Command. To mark the unusual occasion, key personnel connected with the design and manufacturing of the first batch were presented with petrol lighters – which Mr. Wielanier was manufacturing as a business before he turned to gun manufacturing. Each lighter was engraved with two legends: ‘Polish Industry, November 1943’ on one side, and ‘Christening of Błyskawica’ on the other.

A Lightning for the Failed Tempest

In order to avoid compromising of the entire program should the Germans discover the manufacturing plant, parts were contracted from over twenty various manufacturers, scattered throughout the entire city. A chicken-wire factory ‘Franciszek Makowiecki & Co’ located at 20, Grzybowski Square in Warsaw was tasked with the final assembly and test-firing of the submachine guns. The clandestine SMG plant was situated under the legal workshop, in the cellars of a nearby Roman-Catholic Church of All Saints. An additional concrete-lined tunnel acted as an underground shooting range for functioning tests. The walls of the tunnel were doubled, with space left between the two layers of concrete walls to suppress the report of the firing guns, and a sandpit was installed behind a wall of wooden railway sleepers as a bullet stop. Five people were assembling and test-firing the guns, the test being performed strictly during the rush hours to use the street noise as means of additional sound camouflage. When people were working in the clandestine plant, there was a special look-out on duty in the official workshop, tasked with switching the warning light to alarm the assembly workers if anything suspicious was going on topside. The facilities were mined with explosive charges to blow the workshop up, should Gestapo raid the premises and find the camouflaged entrance.

The first trial order was for five prototype weapons to test the cooperation network and for further function and troop testing. Upon the trial batch tests, the Diversion Directorate of the Home Army’s HQ placed the main order for an unprecedented 1000 submachine guns to be manufactured and assembled at the clandestine workshops. Close on the heels of this first order, a second one for 300 guns followed. Until July, 1944 most part kits for the 1000 guns order were manufactured, and as much as 600 Błyskawicas were taken over and accepted by the Home Army Ordnance Command with additional 100 assembled in July, in preparation for the uprising in Warsaw. After the uprising started, the assembling shop with most of the component stocks was evacuated to the no longer secret workshop in city center. As many as 40 weapons were completed there, the main limiting factor being – ironically – the shortage of Sten barrels, which had to be left in Teofil Czajkowski’s shop on Leszno Street, in the now German-held part of the city.

The production numbers are subject to the heated debate. The 755 manufactured SMGs number is based on the actual Home Army units materiel reports, some of which might be missing. As with all the clandestine manufacture projects, the secrecy meant that consignee had only a limited degree of control over the actual numbers, and the supply network leaked. The thirst of war-fighting weapons was so powerful, that nobody was able to guard them securely from people often desperate enough to go and get them bare-handed from the German occupiers. This was also one of the reasons for subcontracting manufacture throughout the city – if any of the manufacturers fell to the urges of nepotism or corruption, all he could offer outside the Home Army network was bits and pieces, and not the complete guns, commanding premium prices on the black market. But even the assembly shop workers, devoted people and sworn soldiers as they were, may have had various favors to pay for, could have stashed several guns for their own use, or hand over a Błyskawica or two to the friends in the other factions of the Polish underground, thus raising the overall number slightly higher. But even if these reports are inflated (which is highly unlikely, as the Home Army was running a very tight ship, money-wise) and the number was, say 555 instead of 755, this is still a fantastic achievement. To invent, design, series-manufacture in clandestine shops of the occupied city and then assemble, test-fire and issue to the underground army several hundred units of an entirely original model of a submachine gun, still remains a marvel of organization. Only Sten look-alikes manufactured all over Europe could compete in numbers with the Błyskawica, but none of them was of original design. The relatively high number of the surviving Błyskawicas, some of which even got abroad (at least one gone as far as Prague in Czech Republic, where for decades it was labeled as a… German Sten copy, another was reported as far as Italy!) coupled with a multitude of period photos, and even movie footage showing this little gun in action, supports the high production number. The Warsaw Uprising newsreel had a feature showing the assembly workshop at Boduena Street with rows upon rows of receivers in various stages of completion. Unfortunately, the majority of the guns assembled prior to July were transferred to the Eastern provinces, where units were alerted to stage the eventually aborted Operation ‘Tempest’ in front of the Red Army, and subsequently lost.

Ready weapons were smuggled out of the factory, in 10 guns batches, inside hollowed wire-mesh rolls. Initially the new weapon was restricted for the general uprising mobilization storage only, and any use of them closer than 100 km from Warsaw was strictly forbidden in order to camouflage the manufacturing area. The overall Burza (‘Tempest’) plan written in winter 1943/44, called for a general uprising rolling gradually throughout the country in front of the Soviet offensive, to disrupt the German transport and defenses, tie-up German forces away from the front thus helping the Soviet push – while at the same time showing the Soviets that the Polish Underground State led by the London-based Polish government in exile is a force to reckon with. These plans generally came to naught, because the Soviets were unwilling to take the proposed help, and treated all non-Communist armed outfits in their front zone as hostile.

The Home Army’s zeal to help Soviet offensive petered out after the Vilnius liberation on July 13, 1944. This was the first major pre-war Polish city in the path of the Red Army, and it was liberated by the joint Home Army and Soviet forces. The liberation honeymoon lasted no longer than three days, after which the Soviet front troops were replaced by the NKVD security police, who arrested all Home Army soldiers and deported them to Siberian prison camps, as… Nazi collaborators!

Plans were also drown up to liberate the capital of Poland, Warsaw in front of the Soviet offensive. The Błyskawica production was thus intensified in June and July 1944, with a daily output in the last days of July reaching up to 25 submachine guns assembled, checked, and shipped to mobilization storage. This surge was possible, as the Germans were in full retreat through the streets of Warsaw and security was much less strict than just weeks before. After the Vilnius fiasco, the issue of the Warsaw uprising was temporarily put in a limbo, but on July 22, 1944 the Soviets installed a puppet government in Lublin, the first major Polish city behind the 1939 Soviet-German demarcation line – thus clearly signifying, that they intend on permanently detaching all the Eastern provinces (54% of the pre-war territory!) from Poland. This was a major threat to the national survival, and a symbol was needed to mark the presence of the Underground State and boost the nation’s morale. The uprising plans were reinstated and thus on August 1, 1944, the Warsaw Uprising broke out.

A week earlier, with Germans in full retreat, this venture could have really become victorious. But on August 1, the Soviet summer ‘Bagration’ offensive steam-roller was already slowing after a lightning-fast charge that covered almost 700 kilometers in two months. The Germans started to reinforce their defenses along the Vistula River, with all the troops channeled through Warsaw, a major communication hub. German forces garrisoning Polish capital almost doubled overnight, with as much as two Panzer Divisions, including the elite ‘fire brigade’ Hermann-Goering Paratroop-Panzer Division, camping within a rifle shot from the city limits.

The Błyskawica production recommenced on August 4, and lasted till August 20, when the reserve workshop got bombed. The last Błyskawicas made there were often lacking the aluminum barrel jacket, replaced with a simple steel threaded plug, securing the barrel.

Błyskawica From Muzzle to Butt Plate

Błyskawica is a straight blowback submachine gun firing from the open bolt. It has a folding stock, a vertical magazine well and is chambered for the 9×19 mm Luger round.

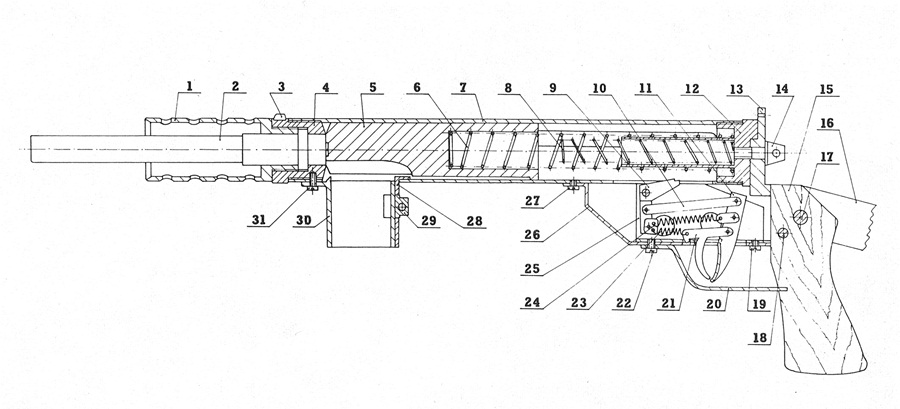

The Błyskawica SMG main component groups are: upper receiver, barrel, lower receiver, magazine well group, breechblock group, return springs group and the magazine. The design kept complicated machining to a bare minimum, with most component parts turned rather than milled, and most connections made by fine-threads and machine screws, to avoid troublesome welding.

The manufacturing technology, governed by availability of the tooling and production methods, was very primitive and crude even for the 1940s. The guns were made mostly of the machined tubing, with as few soldered sheet-metal parts or aluminum castings as possible. Components were connected mostly by means of threads and screws, which made field-stripping a very time-consuming procedure.

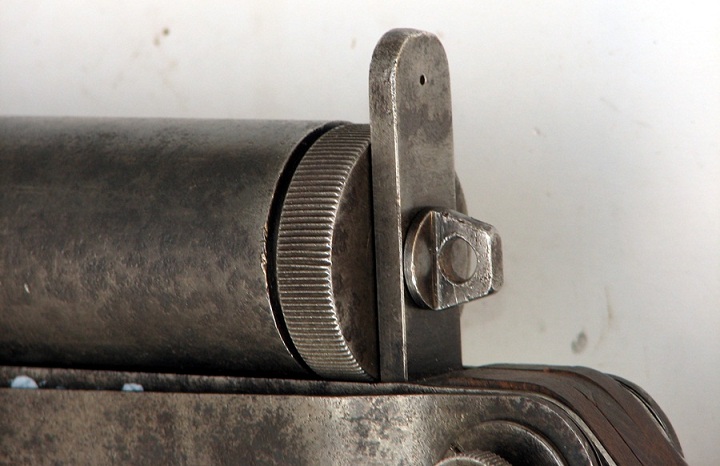

The upper receiver is made of the length of plumbing seamless tubing, with retracting handle slot, ejection, magazine well and sear openings. The barrel supporting plug is bolted inside the front end, while the rear end is threaded for the end cap.

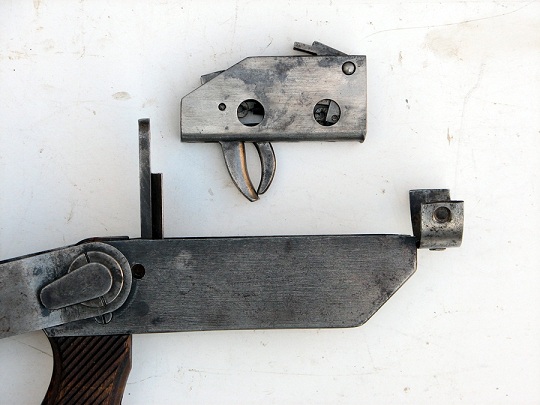

The lower receiver group includes a folding stock pivot, trigger mechanism, trigger guard and a wooden grip. The trigger mechanism is a self-contained entity, inserted as a whole into the lower receiver.

The magazine well is welded of the two halves, with a magazine catch assembly screwed on the back of the housing. A projection of the magazine well fastener extends into the receiver to serve as an ejector. The magazine well is fastened to the receiver with two screws.

The barrel is 197 mm long, patterned after the Sten and made fully interchangeable, having six lands and grooves with right hand twist. It is inserted into the barrel plug and then tightened by an aluminum barrel jacket screwed on top of barrel retaining collar. The Sten type barrels were mass-produced by the Teofil Czajkowski’s workshop in Warsaw, along with other 9 mm barrels, e.g. the Vis pistol barrels, to be assembled in handguns smuggled out of the German-controlled Radom factory. In an attempt to stem that flow, Germans moved the barrel manufacture and final assembly to the Steyr factory in Austria. This move rectified the situation only for a few months – then Czajkowski’s shop opened and smuggling Radom parts again became a popular pastime, despite public executions of all caught in the process. The quality of Czajkowski-made Sten barrels was depending of available steel, but manufacturing standard were usually slightly better than the average original – especially the 2-groove Mk 3 barrel.

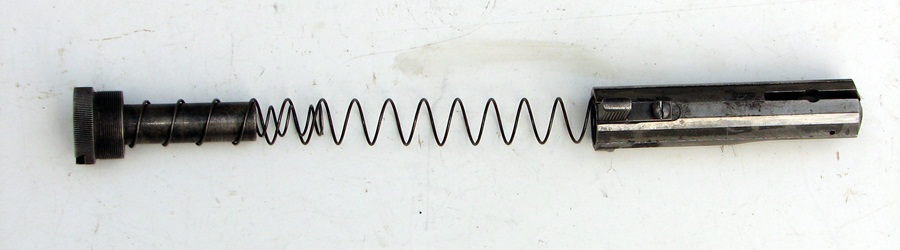

Błyskawica has a heavy (720 gram), massive breechblock with the feed/extractor channel and sear notch cut in the underside, and a hollowed-out rear, where a return/bumper spring with its guiding/dividing tube fits. The firing pin is rigidly installed in the bolt-face, as in the Sten. A dove-tailed channel for the retracting handle base is cut on the outside of the bolt. The breechblock is machined out of the solid steel rod, with driving ribs machined along it to ease friction and channel the dirt, much like in later George Patchett’s Sterling SMG. The ribbed bolt is in fact a reversal of the MP 40 layout, whereas the bolt was cylindrical, and the receiver tube corrugated to form the stiffening ribs, which the bolt glides along. This feature was very highly rated by the Polish designers examining the captured German SMG, but limited production resources prevented copying that. With no sheet metal die-pressing technology on their disposal, Polish designers had to devise something ingenious to retain the useful feature, while at the same time keeping the technology simple as possible. Błyskawica receivers were made out of length of seamless tubing, much stouter than sheet-metal, so pressing the ribs in them was out of question. Wielanier then proposed a logical alternative: if we can’t groove the tube for bolt interface – let’s groove the bolt for tube interface! And so the designers have reversed the procedure – after turning the breechblocks on the lathe, these were moved to a milling machine and skids were machined along it, resulting in a ribbed breechblock inside a smooth receiver.

There is another feature also strikingly resembling the Sterling – a dual concentric return spring dubbing as a buffer. The longer (320 mm) outer spring of 22 mm diameter acts as a main driving spring, while much shorter (110 mm) bumper spring of 15 mm diameter cushions the bolt in the rearmost position and helps it gain initial momentum for the next cycle. The bumper spring is inserted inside the guiding tube of the spring plug, dividing it from the return spring resting on the outside of it. As with the bolt ribs, the dual springs arrangement was also a part of the MP 40 legacy rather than having anything in common with the Patchett. The spring telescope of the MP 40 contained two springs – long return spring, and a much shorter bumper spring installed into the front portion of the telescoping cover, with a bumper casing incorporated into the firing pin base. Reproduction of the spring telescope was out of question due to its complexity – and the general redundancy of it. Again, something simpler was needed, and again, the answer was to reverse the German idea. Both springs were installed in the rear part of the receiver, with outer driving spring fitted around the receiver end cap/spring guide, and inner bumper spring inserted into it.

Making the rear surface of the barrel plug and bolt’s front facing surfaces convex is another interesting feature of Błyskawica, enabling the dirt to accumulate there without hindering the action. Both surfaces scarcely made contact except for dry-firing, as the Błyskawica employed an advanced primer ignition scheme, common for submachine guns firing from an open bolt. In connection with the bolt ribs it proved especially useful in urban warfare during the Warsaw Uprising, when there were plenty of rubble and brick dust in the air, enough to jam most other, much more renown submachine guns. Breechblock cylinders were turned on a lathe in pairs, disguised as shafts. Then ribs were machined into these, and spring channels drilled into either end. After these operations, the ribbed hollowed ‘shafts’ were cut in two on a lathe, using a triangular-shaped cutter tool, then all other openings (for the extractor claw, dovetailed cocking handle slot, bolt face with a firing pin shaft) were executed.

The trigger mechanism is of very simple design, bordering on crude, but nevertheless fitted with an advanced automatic trigger safety. The spring-loaded safety forms a part of the trigger linkage. The safety lever extends into the trigger guard, while the nose of the safety is inserted into a notch in trigger mechanism casing, thus immobilizing the trigger. To operate the sear, shooter has to insert his finger between the safety lever and the trigger to deflect the former and unblock the latter. There is no other means to make the gun safe with the bolt in battery or retracted – in fact, apart from the automatic trigger safety, there are no further safeties at all! This was infamous as a very failure-prone safety, though, and many accidental discharges were noted after bumping the stock on the rubbles in a ruined city. There is no fire-selector either, but heavy bolt keeps the rate of fire low enough to make squeezing-off single shots relatively easy.

The stock has twin struts made of steel flats and cast aluminum stock plate. The stock is folding underneath the receiver, and its length of pull is governed by the measurements of the receiver, which makes it rather short for the average shooter. A different butt-plate, U-shaped to clear the magazine (like in AKS-47) would have helped to lengthen the stock. Here again the ignorance of the designers and the strength of the MP 40 influence is obvious – it folds under the receiver, even though a top-folder like the Soviet PPS 42/43 or a side-folder, like Reising 55 or Sten Mk IV, would enable to use a longer, more comfortable, stock.

The sights were rudimentary, with a peep sight rear and inverted V, very low front post, difficult to shoot precisely at anything more than possibly 30 yards away. These are clearly patterned after the Sten sights, but reveal little experience with the peep sights on part of the designers. This is hardly surprising, as these were a novel feature for the Polish military weapon – in fact Błyskawica was the first and only Polish peep-sighted martial firearm until the advent of the PM-84P of 1990s! The peep itself was much too wide, of almost ghost ring proportions, while the pyramid front post was way too small, making it hardly possible to aim precisely. The peep is located on the end cap stop, on top of a dovetailed projection of the lower receiver, while the post is situated on the barrel plug, bolted to the receiver. The placement of sights on separate parts with a degree of play between them made precise aiming difficult.

The magazine is of typical Schmeisser double-row-single-position system, employed for the German (MP 28, 38/40/41), as well as the British (Sten, Lanchester), the American (M3 Grease Gun), Romanian (Orita) and Soviet (PPSh 41) SMGs. It has a wide body, containing a staggered row of rounds, culminating with a conical upper part, channeling the two rows into a single position feed. Inside the body runs a sheet-metal follower, propelled by a follower spring. The magazine is closed with a magazine bottom plate, locked by a projection of the spring plate inserted into the bottom plate opening. Most reliable and coveted were the airdropped originals, as the Polish copies thereof often lacked in quality, mostly because of the follower springs made of improper – but more readily available – wire.

Action of the mechanisms

With the loaded magazine in place and bolt (5) retracted, the gun is ready to fire while the automatic safety (21), incorporated in the trigger mechanism, renders it (relatively) safe.

With firing finger inserted between the trigger (11) and the safety lever, the latter is being pushed forward, thus extracting the blocking projection from the matching notch in the trigger mechanism casing (25) and putting the safety off. Upon pulling the trigger, it is rotated forward, pushing on the trigger bar (10), which rotates the sear (9) in turn. The sear nose is thus being retracted from the sear notch, freeing the bolt to move forward under the power of both driving springs – the long one (6) actually propelling it, with bumper spring (8) helping to overcome the inertia. The bolt is chambering the cartridge from the magazine, firing it while getting into battery. The expanding gases throw the bolt back, compressing the driving spring. If the trigger is released, the returning bolt engages the sear and thus the firing cycle is interrupted. If the trigger is held back, the cycle repeats itself until there are cartridges in the magazine. There is no bolt hold-open device, so after the last shot is fired, bolt stays forward.

Elementary disassembly procedure

1. Unload, clear, check and double check the weapon.

2. Unscrew receiver end cap bolt.

3. Unscrew the lower receiver retaining screw, then slide down the lower receiver until it separates from the upper.

4. Unscrew the upper receiver end cap and withdrew the springs.

5. Unscrew the cocking handle retaining screw, separate the handle from the bolt and remove, then withdrew the breechblock.

6. Unscrew the barrel jacket and take the barrel out of the receiver.

7. If necessary, unscrew the trigger pack retaining screws from the lower receiver and take the mechanism casing out.

No further stripping is needed or recommended.

To assemble, reverse the above procedure.

Imperfect, but genuine

For years the Błyskawica has often been mistaken for a German gun, which it never was. Even if authors do recognize the Polish pedigree of the gun, then they most often mistakenly label it as a Sten copy – which is simply not true, either. The Sten magazine and barrel were incorporated into the design only because these parts were already being manufactured by the underground factories in huge quantities, and so the choice was governed by logistical factors, not a need – or desire – to copy them.

The chief disadvantage – especially in the dusty urban warfare conditions – was a time-consuming and complicated field-stripping procedure, calling for driving out numerous, small, easy to loose screws. The micro-grooved threads were vulnerable to dust, often jammed and got torn-off during field-stripping or reassembly if excessive force was used. The worst idea of it all was the aluminum barrel jacket. In theory, it was designed to transfer and dissipate the heat from the barrel, but in reality no one in the underground had enough ammunition to make the barrel glow anyway… The downsides of the aluminum barrel jackets were numerous, but just these two should be enough to get rid of it. First, it was left silver and shined on, prematurely warning the enemy of the shooter’s position. This is confirmed by the original Warsaw Uprising imagery, both stills and footage – in most cases a shining barrel jacket is the first thing enabling one to recognize the Błyskawica submachine gun held by an Uprising soldier. Second, it was held by the same micro-grooved thread that secured all other components, and thus – if the dirt was enough to jam and damage the threads cut into steel components, then steel thread was sure to scratch and tear the aluminum barrel jacket. These were frequently damaged, and as the threads got obliterated, the gun could be thrown away as well – it was the barrel jacket that held the barrel inside the receiver and took the hammering from the heavy bolt if dry-fired. Some late September – early October 1944 photos show at least one Błyskawica fitted with an exposed barrel and a short steel plug screwed into the receiver instead of the aluminum barrel shroud.

The abysmal sights could have been easily rectified, by placing both of them onto the upper receiver. The sighting radius would be shortened by no more than an inch, and both would be finally placed in line. With a smaller peep and higher, shrouded front sight post, the Błyskawica would be a very nice and a lot more accurate gun indeed. As I fired a rare shootable survivor (held at the Police HQ Forensic Lab, unfortunately not allowing photography) it was a real pleasure to shoot, well balanced, and grouping nicely – even if a foot up and to the right off the aiming mark at 15 meters.

For no obvious reason the cocking handle of the Błyskawica was a very complicated affair, set into a dovetailed machined channel on the outer surface of the bolt and screw-retained there, with no provisions for securing the cocking handle in battery or retracted position to preclude slam-fire accidents. This is unreasonable at best, especially as Sten with its rod-like cocking handle was one of the ‘organ donors’ – if the Mk5 handle with its projection inserted into the receiver hole was copied, many later accidental discharges could have been avoided.

But generally speaking, for the first gun ever designed by the two men never even remotely connected with the arms industry, it is a remarkably original and successful design feat. Despite the primitive technology, surviving examples show exceptionally good workmanship and standard of fit and finish.

These guns were not enough to win the victory for the insurgents, who fought a 63-day long gallant and deadly battle, left to fend for themselves by the approaching Soviets, who were watching idly the city’s ordeal from the other side of the Vistula River. Stalin ordered his huge summer 1944 offensive to a screeching halt, in order to let the Nazis sort out the Poles before he occupied their capital. Betrayed insurgents paid a tremendous price for their audacity, as the Germans pummeled the city with shells and bombs, burned, and methodically blew up street after street with controlled demolition (often on top of the inhabitants herded into cellars). As many as 200 THOUSAND people died (just imagine –9/11 repeated day after day, for 63 consecutive days in just one city), 90% of them civilian non-combatants, caught between the rock and a hard place. The Western Allies have proven unable – or unwilling – to make their Uncle Joe change his mind and save Warsaw. A mere 700 submachine guns – be they even of the most technically advanced model – were not enough to secure the victory against such tremendous opposition.

Weapon designation: Błyskawica

Country of origin: Poland

Caliber: 9×19 Luger

Type of operation: Blowback

Type of fire: Fully automatic

Cyclic rate of fire: 450-500 rpm

Length with stock extended: 730 mm (28.74 in)

Length with stock retracted: 556 mm (21.89 in)

Barrel length: 197 mm (British Sten barrel)

Weight, unloaded: 3.22 kg (7,1 lbs)

Weight, loaded: 3.83 kg (8.44 lbs)

Type of feed mechanism: Stamped sheet metal box magazine, staggered row, single position feed

Magazine capacity: 32 rd (British Sten magazine)

Weight of loaded magazine: 0.615 kg (1.355 lbs)

Number of lands and grooves: 6

Rifling twist direction: RHS

Approximate muzzle velocity: 360 mps (1180 fps)

Sight, front: Blade, inverted V

Sight, rear: Fixed aperture, set for 100 m (110 yd)

Safety arrangements:

The spring loaded safety lever blocks the trigger unless rotated forward by a finger reaching for the trigger. No other safety arrangements.

Means of controlling operation:

The retracting handle is located on the right side of the receiver.

You can see all the photos of the Błyskawica here (click to download both galleries as a high-res archive):

[nggallery id=156]

We also have several vintage photos of Błyskawicas in use:

[nggallery id=157]

Thanks You! It’s very impressiv! Ukraina Kiev

What a great article. Thank you very much.

Amazing article ! Great job Leszek and thanks to Ian for posting it!

Such a shame I don’t understand Polish and can’t read Strzal 🙁

An incredibly enlightening and fascinating in-depth article on a rare and often-ignored weapon, and the courageous endeavours behind its design, manufacture and usage under appalling conditions. Leszek has done a terrific job from a technical, historical and humanistic standpoint. I don’t think we could thank him, and Ian, enough for sharing this unforgettable piece of history.

Great article on a truly forgotten weapon. Congratulations to both the site owner and the author, for making this available to a wider audience.

I have a small question for Leszek regarding the Błyskawica finish: what sort – if any – of surface finish was originally applied by the brave makers? The photo at the end of the text, depicting three young fighters, two lads and a young lady, seems to indicate some kind of blueing.

Great article indeed.

The specimen I once saw at the collection of the German Federal Police was blued (except the barrel shroud of course).

@ JPeelen: thanks for the description of the specimen you saw. It pretty much confirms the impression one gets from the photo.

“For no obvious reason the cocking handle of the Błyskawica was a very complicated affair”

Au contraire, very obvious reason for this arrangement was the design of recoil spring that along with the recoil spring carrier in the back, penetrated the bolt body in rearward movement.

Usual and simple Sten type cocking handle made on the lathe could not be used here, as it would get in the way of the recoil spring carrier and spring itself, protruding in the empty space drilled in the back of the bolt.Remedy to this is not easy fixable, for example,

simply drilling and tapping a hole to use some kind of threaded cocking handle would not be a good solution since the thickness of the bolt material is not enough to provide enough threads per inch, so that cocking handle would unwind and fall off easily.Here it is indeed drilled tapped but with smaller screw and cocking handle is held not to fall out with dovetail arrangement, so it is a little better. Maybe if they invented (rather modded a little to achieve) system like thats used on Sterling smg it would work out better; by simply placing the round part on the end of the spring resting in bolt, with hole drilled perpendicular to the same hole drilled in the side of the bolt, so this is the place to insert the rod-like cock. handle.

But given the circumstances of this gun production, everything is remarkable by itself !

I have to disagree with many of the comments in this article, for instance in the “Let’s Roll Our Own” section I am left with the impression that the MP 40 is almost considered a completely different gun that the Sten when in fact the Sten is essentially just a side fed MP 38/40.

The Polish gun seems to be an attempt to reinvent the wheel which just made it more complex without any advantage in the process.

Very cool! I’d love to see a video on this and even more, a video of you firing one!