I’m flattered to say that we received another research question from the Pattern Room, and a bit dejected to say that once again it was something I couldn’t provide a good answer to. However, the information that is available is certainly interested by itself, and perhaps someone reading this will recognize the gun and be able to tell us more about it.

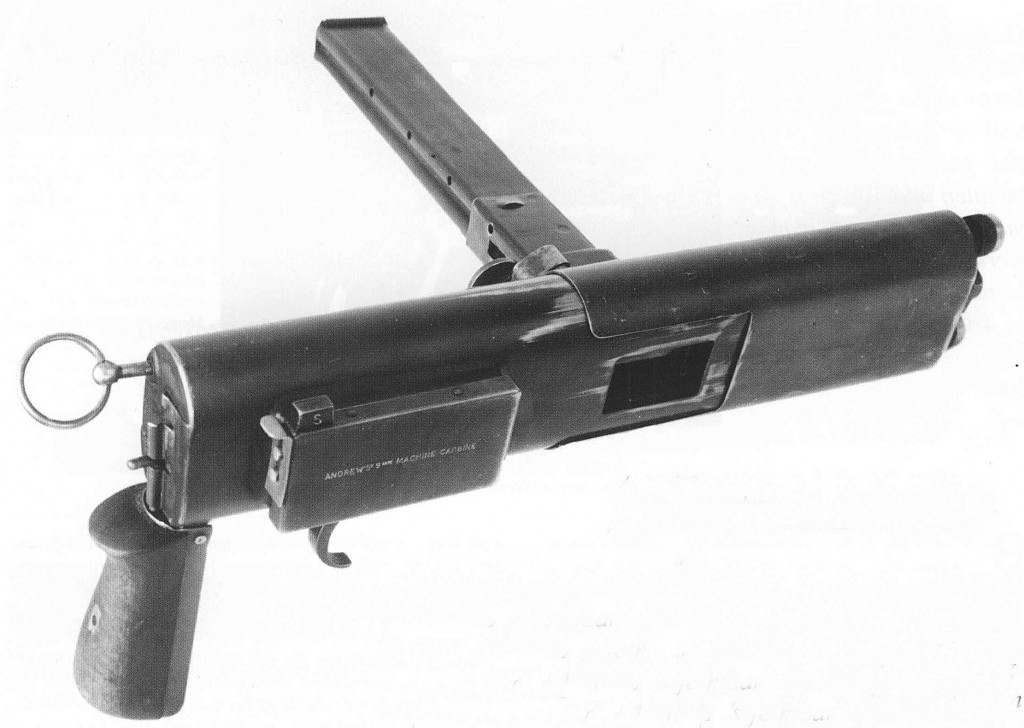

The gun is the Andrews Machine Carbine:

This photo (and the other two below) came from a Dutch gun magazine, where they accompanied an article which said, basically, “we have no idea what this thing is an no other information on it”. One of Ian Hogg’s books does actually reference it, and that is really the only source of information about it, aside from inferences made form the photos. So, here are the data point that Hogg mentions:

- It was designed by an Australian, named Andrews

- It is chambered for standard 9mm Parabellum cartridges

- Prototypes were made in 1943 by BSA, for British Army trials

- It used two full-length guide rods, one above and one below the barrel

- The guide rods carried a pair of recoil springs, as well as carrying the bolt inside the receiver

In addition to this information, a couple things are apparent:

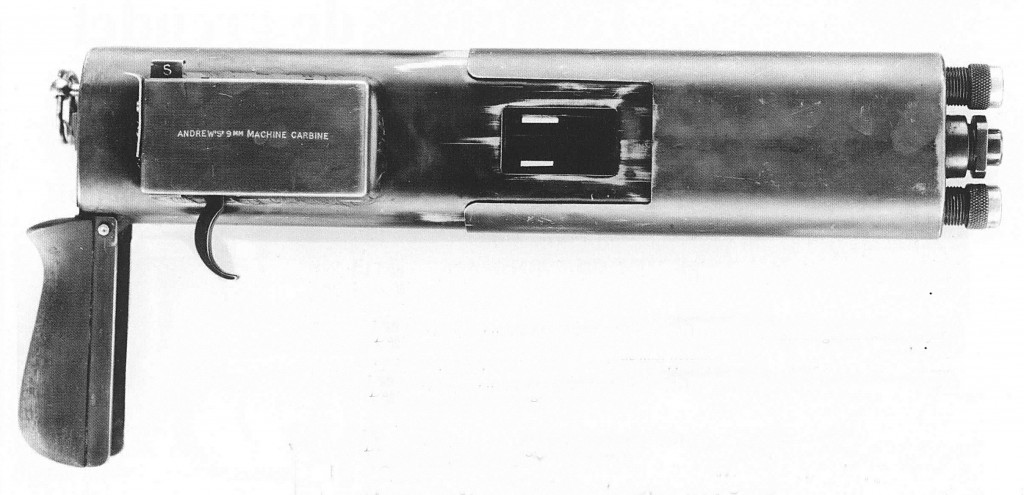

- The gun uses standard Sten magazines

- The bolt occupies the full volume of the inside of the receiver, thus requiring the firing mechanism parts to be mounted on the outside in a separate housing

- It has a sliding dust cover to close off the ejection port. Not clear if it is manual or opens automatically when firing

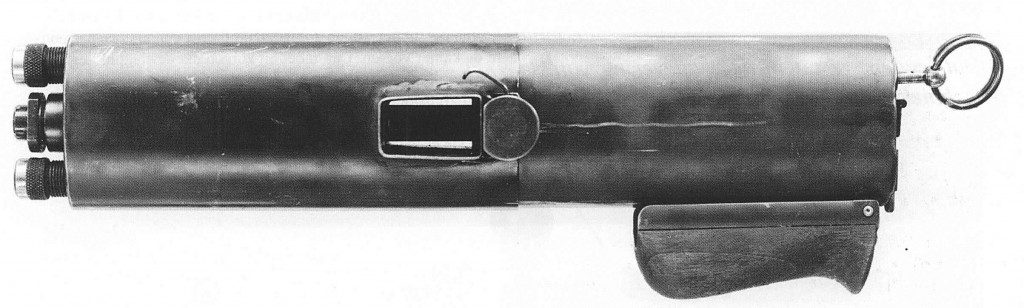

- The grip folds up, although is does not cover the trigger (which is offset on the right side of the gun)

- It is equipped with a sling or lanyard loop on the back of the receiver

So much for the facts. Now, for my speculation…

The compact design, folding grip, and sling loop and suggest to me that this was intended to be a covert weapon intended to use by the Cloak & Dagger folks. With the grip folded and no magazine (and presumably without have “MACHINE CARBINE” engraved on it), this would not look like a firearm to the casual observer. It could be carried hanging under the arm, rather like a Bonnie & Clyde style whippit gun.

Mechanically, it appears to be a pretty straightforward blowback submachine gun. The trigger group being mounted on the side looks unusual, but really isn’t any more complex than the standard mounting position under the receiver, and does reduce the overall dimensions of the piece. Presumably the threaded guide rod connections at the front would have been much similified once the gun went into serial production (which never actually happened)…although perhaps they were intended to make the gun look less like a gun.

As far as anyone can tell, this never went past prototype stage, and most likely there are no surviving examples of the gun. If anyone knows more about it, we would be very interested to hear from you!

I would hate to imagine firing this awkward gun. But then again, if it could have a suppressor fixed to it, things would take a different turn. Could you disguise this as a gift-wrapped present? Oh, boy, would I like to get this thing… And it would not be good for the person on the receiving end of the suppressor-Special delivery, anyone?

Sort of a overt, Welrod.

Like it…

Are the recoil springs running along the guide rods being compressed by the front of the bolt like a slide rather than them sitting behind the bolt if you follow me, the bolt “telescopes” over the barrel so I was wondering if the springs do also.

Can’t say for sure, but I would suspect the springs are behind the bolt.

I think the enlarged front section collapses over the narrower rear “receiver” half. And the recoil rods have two separate springs over each, with a plate running over the rods to the front which is attached to the front of a telescopic bolt over the barrel “with the springs above it” behind the two front springs on either rod is a further plate running over them.

This can be locked in place towards the front of the inner “receiver” section, and drilled so the telescopic bolts outer fits through it.

At this point if you imagine this plate was locked, and one is pulling back the bolt, its forward plate will compress the springs running along the rods, via there rear coming to a stop on the plate aforementioned.

Now if a further set of springs sat behind this plate, the bolt could be compressed as aforesaid but the springs to rear of it could also be compressed if the plate was unlocked via the rear of the rods running through a further plate behind the end of the rear set of springs via this plate being attached to the inside of the inner receiver towards it’s rear.

The rods would pass freely through them when the outer section “through which the front of the rods protrude, and are presumably attached to” is compressed over the the inner section, allowing the gun to collapse with the bolt cocked separately from the tension imparted on the collapsed section which is locked into place.

By say a pin, anyway pull this pin out and the rear springs can expand the rods to the rear compressed by there springs slide forward through the rear plate… The front section is now forward, but the bolt is still to the rear under pressure from the forward springs.

Need a pen and paper, anyone kind of following me? I must confess I’ve lost myself, in regards the locking of the middle plate somehow!

Ian, I agree and follow. I have some ideas on this one.

The lanyard loop looks to be the charging handle. The whole thing looks like it’s designed to stop dust from getting to components, so the bolt is covered and that’s the only way to cock it. Good for sandy volcanic beaches?

My speculation is that the telescoping portion slides back first and noticed that the magazine well would move back with it completely covering vital components. The pistol grip would then be folded against it. Maybe the trigger somehow folded up in to the housing that probably held the safety and firing mechanism. Looks like the bolt is forward in the images. Could be when stored the barrel and guide rods were either exposed or somehow telescoped (seems too complicated for wartime expedience) or even removed (too complicated for combat). With those rods and the barrel exposed it could also performa cocking action, but that rod connected to the loop clearly goes in to the receiver. I’m imaging a hook on the end of that rod going in to the bolt to lock it back.

I could almost draw this on paper, how I think it might work. Thinking like a World War minded arms designer, this has to be almost stupid simple.

My first impression is that the “lanyard loop” may actually be used to cock the weapon as I see no other means of retracting the bolt. Looks fairly awkward…

“My first impression is that the “lanyard loop” may actually be used to cock the weapon”

I think that is exactly right. I’ve seen a similar arrangement (minus the ring) on at least one other submachine gun, if I recall correctly, the one vaguely shaped like an Uzi with an M3 stock, which takes MP40 magazines.

Just figured out which gun has a similar cocking mechanism: the Atchisson M1957. It’s almost exactly the same sort of rear protruding rod, minus the ring.

A firing port weapon for tankers? The Austen and Owen would be a bit large for that application.

It would have been handy for that probably.

Well, you’ve got me. This is the first I’ve heard of this one, let alone seen it.

I agree it looks suspiciously like a black ops weapon. The old Welrod silenced pistol, with its magazine removed, looked enough like a bicycle air pump that you could probably toss it in a tool bag on your bike and not attract too much attention from the average German soldier in occupied France.

As for its operating procedures, that “sliding dust cover” up front seem to have the magazine housing rather firmly attached to it on the left side. I’m wondering if it isn’t in fact a cocking slide, rather like the one on the BSA prototype 9mm SMG of 1949. (Small Arms of the World, 10th ed., p. 260.) “Andrews” may have worked on that project, as well.

The tab marked “S” atop the lockwork box on the right side may be the safety. Pull “up” exposing the “S” for Safe, push “down” flush for Fire. I’m not sure if the tab on the two rivets (?) behind it is connected to it. Could that be a semi/auto fire selector?

The fact that there are no sights tells me that this is a toolroom job. The idea being to see if it actually would work.

Finally, the mounting and securing system around the muzzle and the two recoil spring guide rods makes me suspect that this weapon was to be fitted with a detachable sound suppressor, rather like the one on the single-shot “Sleeve Gun” member of the Welrod “family”.

Such a suppressor would probably have had the same “elliptical” cross-section as the gun body, and might well have used the principle of a baffled “tube” that bled high-pressure gases into a pair of vented expansion tubes parallel to it, as per the Eugene Thurler patent of 1911. ( Firearms Silencers, by Donald B. McLean, Normount Armament Co., 1972. Vol 1., pp. 84-85.)

McLean notes that at least some limited production of suppressors to this pattern took place in Europe between the wars, and post-WW2 a Walther PPK 7.65mm using a similar suppressor was issued to CIA units in Europe. (CIA Special Weapons and Equipment by H. Keith Melton, Sterling Pub., 1993, p. 23.)

Yes, this is all speculation, take it for what it’s worth.

😉

cheers

eon

Good point about needing some sort of cocking mechanism – I didn’t think about that. Could the the lanyard ring, like DR says, or the sliding cover…

The lanyard (cocking?) ring appears to be in a different position closer to the receiver in the third pic insinuating it moves back and forth at least a little… and also, I wonder, does the magazine well move with the dust cover? In addition to the finish wear 2″ or so behind the cover, there is a longitudinal scratch backwards from the rear midpoint of the mag well in figure 2. Perhaps you pull back on the mag well?

I think you cock it by the holding the magazine and pulling it rearwards also, in so doing you cock a telescopic bolt wrapped around the barrel via it staying to the rear so it can fire from an open bolt, when the outer returns forward under it’s own spring pressure as alluded to in another post of mine which admittedly is somewhat rambling. Anyway you then lock the outer into this forward position for firing, via the moving the “ring pull” in some manner. I also think you can depress the outer over the inner, so it collapses the gun into half its size, again facilitated by the pin.

I may be wide off the mark, but I can’t imagine cocking a Sten gun with a ring pull without a fair deal of strain.

Me neither. I’m inclined to think that ring aft is for a “dummy cord”. For those not into OSS slang, that was an elastic cord like a modern bungee, but not as strong.

The Sleeve Gun had a similar attachment. The drill with it was to loop the other end of the cord around your shoulder like a lanyard under your jacket, and thread it into your jacket sleeve. It would hold the Sleeve Gun securely inside the sleeve with the muzzle just above your wrist. When you wanted to shoot, pull it out with your off hand, grasp it with your “shooting” hand, fire, and then just let go of it. ZIPP- the dummy cord yanks it right back up your jacket sleeve and out of sight.

With a suppressor on the gun (it was a .32 ACP single-shot), unless someone was looking straight at you when you deployed it, you and the target would probably be the only ones who realized that a shot had even been fired. Incidentally, the Sleeve Gun and suppressor were sturdy enough to make a decent truncheon, too.

This weapon’s ring might have been intended to secure it to a parachutist’s harness, since it’s just a bit too big to go in any of the pockets of an SOE jump smock or “jumpsuit” (see Visual Dictionary of Special Military Forces, Dorling Kindersley, 1993, p. 9).

As Edwin Tunis said of the M1A1 carbine, it would have allowed an agent jumping into “Festung Europa” to land shooting if necessary- with something a bit more emphatic than a silenced .22 High Standard HD or a .32 Colt 1903, and easier to hide afterward than either one.

For “ground” duties, the ring could have allowed the Andrews gun to be suspended down your pants leg. Keep in mind that back then, most men’s trousers were what we’d call “relaxed fit” today. They were loose enough that something the size and shape of a submarine sandwich wouldn’t make much of a bulge hung next to the thigh on the outside.

What I’m finding a bit confusing, though, is the gadget next to that ring on the backplate. It’s very likely a latch to secure the pistol grip in the unfolded position, but I can’t quite work out how it works. The lateral slot would seem to indicate that it works like a door-bolt (possibly spring-loaded?), but there doesn’t seem to be any way for it to move up or down. (Unless the “tube” is open on the left side above the stud, which we can’t see in the photos.)

It could be a rotating “hook” latch, I suppose, but I’d suspect an M1921/28 Thompson-type push-button (the one that holds the stock on) would have been simpler.

All in all, one very esoteric bit or ordnance. The later “folding SMG”-

http://en.wikipedia.org/wiki/ARES_FMG

– has a lot in common with this beast.

cheers

eon

The “ring pull” thing, does appear to be in different positions on different pictures i.e. closer or further away to the rear of the receiver, which may just be a coincidence a sort of swivel pin slotted in to hold said dummy cord. I have heard of that sleeve gun, I think… When I saw the picture of this gun with a magazine as the stock, It stuck me as a image I recognised somehow but couldn’t at all place, most peculiar. Anyway, the OSS use as you outlined I think fits its looks, in that it doesn’t overly resemble a gun really. On the ejection port side, the sort of case deflector thing may also possibly be a latch, there maybe a scratch running inline with it to its rear and if you look at the rear of the receiver were this would catch if the gun collapsed there are perhaps indentations suggesting this. One would release said latch so it didn’t catch, and the gun would expand.

Oh, that’s the magazine catch.

I really should were my glasses, still it could act as outlined above possibly… The toilet style door bolt must fit into a hole, within the grip which isn’t visible I thought.

lol Ian , didn’t see your comment before I’d noticed the same things…

I possibly saw it in a Commando comic years ago, they had weapon pictures on the inside of the covers periodically maybe in a SOE episode. The Russian pp2000 also has the spare magazine as a stock, I might be thinking of that.

I have met ANDREWS – a few years ago now, in Tucson AZ. I believe he worked at Enfield during WW2 and was in the design department where he probably experimented with the weapon illustrated. It may well have been his design.

At some time after WW2 he emigrated to the USA and continued design work on SMGs. He did design at least one which was innovative and showed potential but it never went anywhere. Eventually, after his death, his personally-owned prototypes were collected by an RAAF C-130 and taken to Australia !

Great story, it’s too bad he’s no longer with us to explain it himself!

Fascinating piece of equipment, be super if one exists somewhere…

Though its complete speculation, other period SMGs with folding capabilities were generally intended for use by airborne troops. If some were indeed trialed by the British Army this may well have been the intended use. Otherwise, I would have to agree with other speculation that such a weapon could easily have been made for the SOE or some similar organization in the UK, or for use by partisan forces in Europe and elsewhere.

Distal……I think you are right…the lanyard loop cocks the breech bolt, and has to be pushed forward. If the small rod it is attache to gets bent…the weapon couldn’t be fired. Also I have another idea…The bolt is retracted with the left hand holding and pulling the magazine to the rear. As the magazine housing is attached to this sleeve. Look at the wear pattern of bluing, the sleeve that the magazine is attached to….you can see that it has been drawn to the rear enough to wear the finish. That way both hands never have to move from the “ready” position, when firing the weapon.

David

I would think that the tab prevents the safety “button” from moving to the fire position when it is in the UP position; push the tab down allows the safety “button” to move to the rear into the fire position. Reason is that there is no wear marks forward and if you look at the tab body you will see the slot what allows the tab to move up and down. That slot just barely clears the safety “button” in the down position.

Just my 2 cents.

http://www.thefirearmblog.com/blog/2014/01/22/common-illicitly-homemade-submachine-guns-brazil/

Heh.

I have found a wee bit of extra info from FWA Hobart’s “…Sub-Machine Gun”. The version in the book differs from the one pictured here in that it uses a spare magazine as the shoulder-stock(!); it has a very skinny little pistol-grip; a trigger-guard; and a slightly longer barrel. The text also states that it feeds from the right, but this isn’t apparent from the photo. (Just posted the pic on my blog, here: http://mickimahoney.blogspot.co.uk/2014/01/andrews-smg.html )

It was trialed against the Welgun, Patchett, Austen, Owen and a modified Sten Mk4 twice. Once at Pendine from 22nd Sept. to 5th Oct. 1943 and again at Bisley by the Small Arms School in Nov. 1943. In the first trial, users complained that the casing was too thick for a comfortable hold and the magazine-stock contrivance was liable to come loose — nonetheless, they placed it second, alongside the Austen and Patchett, so it must have had some merit. The second test at Bisley was conducted simultaneously with a test of the Vesely V43, which came out on top.

If the Pattern Room wants to peruse these tests for any more info on the Andrews SMG, Hobart quotes the Ordnance Board: “OB Proceeding Q1755 dated 20 December 1943.”

Looking at the picture you have provided with an extra magazine being utilized as a stock, I am further convinced it was not designed for conventional forces.

Rather for S.O.E or indeed as some form of “liberator” weapon idea.

Well done!

Awesome info, Micki – thanks!

Nae probs — just vaguely recalled the reference and dug out the book, really. Would totally recommend Hobart’s book as a source for Forgotten SMG info, though! I just looked and you can pick up a used copy for under $20 on Amazon.com, or £15 on Amazon UK.

Re: the potential clandestine use of the folding-grip/stockless Andrews in the original post; that does indeed seem likely, in a roundabout way. It looks to me as if the Andrews SMG pictured in Hobart was probably the original and was simply intended as a more compact SMG, rather than anything covert. All the weapons competing in the September-October Pendine trials, (the Andrews, Welgun, Patchett no. 001, Owen Mk2, Austen Mk2 and Sten Mk4B,) had either collapsable or detachable shoulder stocks and were more compact than the Sten Mk2. Although I haven’t read the original report, this rather suggests that the Sten Mk2 was considered overly lengthy for what it was and in need of improvement.

Although it failed to generate any interest, the Andrews was rated equal second-place in the Pendine test, which must have given the designer some confidence. I’d surmise that after orders were not forthcoming, he redesigned it slightly to appeal to the SOE, hence the odd setup above.

Well done Micki you’ve hit the bullseye, there it is.

None of the photos show it collapsed completely. The central idea seems to be shortening the receiver by the recoil travel of the bolt. The cutout on the RHS of the front allows it to clear the trigger housing. Collapsed fully it would be about as long as a Sten magazine.

That would also explain the “rods” on the sides. Extension rather than compression springs.

The ring has to be a non-reciprocating cocking handle. Such a long stalk just for mounting a sling attachment makes no sense.

Weapon for the backup man in an assassination team? Shooter w/ a Welrod and backup w/ an SMG if there’s trouble. The collapsed weapon should fit an overcoat pocket w/o being seen. Which would also explain the lack of sights.

All pure speculation of course.

A collapsible SMG Reg, that would perhaps explain why the trigger mechanism is on the side because the barrel presumably would sit were it usually would.

Maybe that is what the “ring pull” does, opens it out, perhaps it is collapsed under tension and locked, pull the ring and the front section pops out. Like Eon said, the magazine housing appears to be attached to said section. And there are markings on the inner, receiver part to the rear of it which suggest it may move over it.

sounds plausible, depending on the tension required to overcome the catch, it could still be used to attach a dummy cord…pull it into position, it opens..

I do think it is somewhat similar to the Welgun, the imperial war museum mentions a welgun machine carbine as a separate weapon no picture though. A search for it pulled up a Experimental Machine Carbine “It also had an ingenious hinged magazine housing which could be pivoted backwards to allow jams to be cleared without having to remove the magazine and to facilitate cleaning” one quote about it, and another “Interestingly the weapon lacks a bolt handle, instead the EMC was cocked by pushing the foregrip forward and then pulling it back – this pushed a bar which pushed the bolt back and cocked the weapon. The grip was then rotated slightly to disengage the bar and allow the bolt to cycle once fired” might have some bearing on the Andrews as it is later design.

The Andrews barrel, which is protruding possibly appears to be inside a sleeve… And what is the sort of oval nut on its end, maybe it is a thumbscrew you turn it to lock the gun in the firing position or something.

Going back to Small Arms of the World 10th edition, there’s a photo of the Welgun at the bottom of p. 258. It makes an interesting comparison with the postwar French MAT 1949 9mm SMG, which almost qualifies as a true “machine pistol”.

On the facing page (259) is a full-page spread of the EM2 SMG prototype, which absolutely is a machine pistol. And may have been the very first SMG design with the “overhung bolt” we are familiar with today. EM2 was intended specifically for SpecOps forces, and with a suppressor would certainly have been handy for the SOE/OSS groups.

On p. 262 are two photos of the Sten MK IV A and B prototypes. Yes, there was a “MK 4”, between the “3” and the “5”; it was a short-barreled Mk II with first a rear-mounted and later (B) midship pistol grip. Both versions had a stock working rather like that of a Karl Gustaf M45, except with no top strip. The later Sterling “pistol” version of the Patchett-designed SMG owed a lot to this one, I’d say.

The point being that very compact 9mm SMGS were something the Royal Army and SOE were apparently very interested in at that time.

The much later Parker-Hale PDW prototype;

http://guns.wikia.com/wiki/Parker_Hale_PDW

had a lot of “grandfathers”.

cheers

eon

I have read about the Polish chaps EM2 weapon. BSA again like this Andrews, and the EM1 I was having a peruse of patents couldn’t really find anything of specific relevance. The EM1’s unusual cocking method may be in some way connected to this weapon given it sounds plausible via BSA and the mention of a sort of “pump action” This weapon is from 43, one wonders if this accidently created the wrap around bolt. For the purposes of making the weapon collapsible not shorter as it were, then it developed into that.

The upper and lower guide rods resemble the patented arrangement of the XM235 LMG. But the patent was for using the rods (tubes, actually) as the receiver; the external sheet metal casing was nonstructural.

For some od reasons the andrews and the Owen submashineguns, was invited to the swedish tests in 1945, but sqampels nrwer turned up.

Some further observations:

There appears to be a mechanism to latch in the extended position. The LHS has a scratch from it. It’s probably an extension of the magazine catch. This would be required if the springs are extension springs to prevent the weapon folding when cocked. One would need a latch in the closed position if it used compression springs, however, there’s no notch at the end of the scratch on the LHS.

The highlights and scratches in the photos suggest that the receiver cross section is a D. The LHS looks round. That would make internal guide rods superfluous.

It’s got a very short barrel.

The fitments on either side of the barrel are increasingly puzzling. The extent of the “thread” between the “nut” and the front of the receiver don’t make physical sense. The “thread” should be on the other side of the “nut”. But it’s also hard to imagine a fastening for an extension spring that could take that form.

Based on the comment by the reader who met Andrews in the US, I’d be cautious assuming mention of an “Andrews Machine Carbine” meant this weapon. He may well have designed other weapons more suited to general use. This looks rather too exotic, especially with the magazine buttstock arrangement.

More information about the Dutch gun magazine article or any other references would be nice.

Intriguing isn’t it Reg, I am of the opinion it’s purpose was as you alluded to “a concealable, back up gun for Welrod outings” to that end, I think it is a collapsible design as you have inferred. I’ve been drawing how I think it works on paint all day “quiet at work” and I think have partially managed, just about, to draw what I initially conceived as a possible functioning mechanism for it. This is what I outlined in another post, more or less. Anyway by drawing it, I came up with the notion the forward section wouldn’t need a hold open locking latch if it was under spring pressure. And in my mind it is, via the use of separate springs “compression springs” a forward set for a telescopic bolt, and rear set which are compressed via them sitting behind the front panel of the forward section to which the guide rods are attached to via the end caps. In theory “the end caps, are oddly shaped as you suggest” but say they were just holding the rods into the front panel aforesaid, the rear of the rods could sit inside holes in a plate which is attached to the inside of the rear receiver. The rods could pass through if pushed through from the front but they would have a nut on them behind said plate, this would allow the forward section to collapse yet keep two halves of the weapon together. It would collapse under this spring pressure therefore when open the forward section would be fully sprung, so stable enough for a bolt to operate within it. The bolt must be telescopic if it is to collapse in my opinion, in order to fit. I’m going to draw it some more, also in my understanding this would allow you to cock the bolt by pulling the front section rearwards as it would push the telescopic bolt back. The bolt would lock to the rear via a sear in the side mounted trigger mechanism, yet the front section could return forward aligning the magazine back up with the position required for feeding upon the bolts return. If it is a collapsible design I think it is quite exiting, it’s pretty small and innocuous looking.

I do need to draw my suggestion more, I am not suggesting it isn’t making me scratch my head and ponder various issues : )

Just guessing;

1. The rods might indeed be guide rods, assuming that the bolt is rather like that of a MAC 10. There would be two recoil springs housed in tunnels in the bolt itself, bearing against closed forward ends with a smaller hole in each for the guide rods. This would probably ensure smoother bolt movement and more reliable feeding. Incidentally, a weapon with a receiver this short would probably have a relatively light bolt; without some sort of buffer assembly at the rear I’d expect a fairly high ROF, again like the MAC 10.

2. Those front “nuts” might be a combination of a front securing nut and a guide tube co-axial with the rod, probably telescoping as per the recoil spring housing on the MP-40. Why? I suspect that the sliding part, if in fact a cocking slide, had its own set of extension springs mounted ahead of the bolt to return it to the forward position (like the slide of a Browning-type pistol), and keep it there. Since the magazine housing is apparently welded to it and not the frame, some means of securing it in the forward position would be a must to avoid jams in the IA.

This alone might have caused the gun to be rejected for production; simply put, too much complication.

3. As to what to call it, well, it does say “Andrews 9mm Machine Carbine” on the lockwork box.

😉

cheers

eon

Ah, upon firing… The “judder” in conjunction with your hold could misalign the mag, if the front section was just held forward by spring pressure. I was looking at my drawing and I thought “it isn’t holding the front forward, after writing a previous post” I then thought it needed the spring to rest on it’s own lug attached to the rod sat behind the plate to achieve said forward impetus, in my initial conception of how the design might work I thought well the plate aforementioned will need to be locked into position in order for the forward spring holding the bolt to compress against it. And unlocked in order for it to be cocked, and collapsed. Which I imagined might have something to do with that “ring pull” a sort of disengaging rod acting upon a locking piece for the above, the two halves would need to remain in place for sure… The plate could also function as a locking device, it could tilt or something when pulled back by the rod hmmm! He he.

Nelson & Musgrave Machine Pistols and Submachineguns of the World, Vol. IIa (1st ed. 1980), page 472-473 has a minute paragraph on the Andrews at the end of the “Various BSA projects” sub-chapter, simply stating that during WW2 BSA made a prototype SMG for an Australian inventor called Andrews (not to be mixed with another Andrews, an American from Cleveland, who also designed an SMG, covered there on pp. 96-98) which had two return springs on the rods above and below bbl, and used Lanchester mag as a stock – which is shown in a photo on p. 473.

Other than that and Hobart’s book already quoted above – a complete blank.

Would the barrel be screwed to the front panel of the forward section, inside a threaded ring welded to said panel secured by a sort of nut does anyone think? Looking at the picture, the barrel appears to be inside a sleeve of some sort and it has a kind of oval shape on it.

Very possible. The Whitney Wolverine .22 pistol used such a setup with a barrel nut (the modern Olympic Arms recreation has the same arrangement), as did the Beretta M12 9mm SMG.

I’m seriously wondering if this weapon might not have had an “overhung” bolt, due to the position of the ejector port and magazine housing. They are almost exactly where the same setup is on the M12, and it has such a bolt, like the Uzi, Cz23-26 series, etc. It would also be consistent with a twin guide rod system, as on the MAC 10.

Due to the layout, instead of the bolt looking like a long “L” turned on its side;

________

[___]

It might look more like a thick-stalked “tuning fork”;

__________

[___]_____

In some ways, if you thing of this weapon as a MAC “turned on its side”, it makes a good deal of sense. The magazine is feeding up to the barrel between the guide rods, it’s just turned 90 degrees to the left compared to the Ingram design. With the ejection port directly “above” the magazine, rather than at an angle to it, like the Sten and some other first/early second generation SMGs.

Just a guess.

cheers

eon

Well Eon I read your suggestions, and had a wee doodle.

Big smile on my face, as it has fitted together seemlessly using the Mac10 type wrap around bolt and I am confident the guide rods are indeed telescopic hence the funny end caps.

The weapon collapses into roughly half it’s size, about the length of a magazine.

Ahem, well six hours later… Seamlessly, seems something of an exaggeration

This has become my favorite thread here. I really enjoy reading about all the speculation and deductive reasoning into how this gun may have functioned and how such a design might be utilized. I hope more information, or even the location of the prototype comes to light as a result of the interest shown here.

Commendably compact buzzgun, but I share the concern about controllability. Just another dead end in small arms development. I have never seen one of these, indeed never heard of this design before, but I think I would find it much as I regard the Ingram, an interesting way to convert ammunition into noise.

This is the coolest web site ever for people who like odd guns. I saw a holster review on another website, but what struck me about it was not the holster, but the question that came to mind, “who the heck carries a Ballester-Molina?” Then I checked the byline and it made perfect sense. (Great pistol, an unheralded masterpiece.)

http://i1142.photobucket.com/albums/n607/patrickmurphy3/1a/and1_zps6197bf69.png

Above is a link to my photobucket album, were I have put a picture up, illustrating how I think the Andrews may work.

“If the link works”

Well the link appears to have worked, so I will explain the picture. I am working off the assumption that the threaded ends which are visible in the likely location of the guide rods are actually attached to the front panel of the forward section, I am also guessing the barrel sleeve thing is located here as well.

The threaded ends “sockets” are just attached to the front panel as is the sleeve, the barrel is screwed into it, and the guide rods are slotted inside the ends “the guide rods end in a threaded rotatable cap”

The rods are telescopic, essentially a tube threaded at the end you insert through the socket, they pass through a bolt which is wrapped around the barrel. At the end of this a nut is screwed around them, given the bolt recoil spring is behind this nut and to it’s front is the bolt via a hole through it. When you pull back the bolt, the spring would compress on the nut. Inside this tube runs a guide rod which runs to the rear of the receiver, this also has a spring around it which stops via the rear of the nut. If the gun was in the fully collapsed position see the lower picture the forward section is under spring tension via this, if the gun is fully open see the top picture you could hold the magazine and pull the forward section over the rear one via depressing this spring. See the second from bottom picture, by doing this you would pull back the bolt. The bolt would remain to locked “via a sear in the side mounted trigger mechanism” and if you let go of the magazine the forward section would return leaving the gun ready to fire see second picture from the top.

In theory… He he!

Hmmm, possibly a problem with the forward section returning when the bolt is cocked on that model… Which hadn’t been a problem with other ones, what had been was the rods needing to telescope.

I suppose you could put the rear spring inside the guide rod as a possible solution to the above, i.e. the rear rod would “squash” it against the end cap, when you pull the forward section rearwards. Think I’ll have another go, can’t find any more info on it. Apparently BSA was a sort of conglomerate who’s main factory got blew up by ze Germans, so they had lots of places knocking out weapons all over could have been made anywhere. You would imagine there’s one lying around somewhere…

Overall, it looks good. As you suspect, I’m pretty sure this was an open-bolt design using fixed-firing pin, advanced primer (slamfire)ignition.

Putting the guide rods in front with the recoil springs being compressed between their rear end caps and the fronts of the bolt’s spring tunnels is basically the MAC system “in reverse”. Or more precisely, a reversal of the Max Gera AutoMag variant of the pre-WW1 Grant Hammond / High Standard .45 prototype.

It means that in recoil, the bolt relies on the receiver housing for linear guidance, like a Sten, M3, etc., while the spring guide rods mainly provide stiffness in addition to handling the recoil spring loads. This probably explains their front anchorages, i.e., you’d want to be very sure neither rod “unscrewed” itself or vibrated its nut loose while firing. I’m wondering if those odd “double” nuts might not be a locknut arrangement for that reason.

The setup would allow the entire weapon to be collapsed lengthwise, as you show. If so, its “closed” OAL would be about eight or nine inches, or about the size of a medium to small Thermos bottle. It could be tucked inside a jacket, or in a lunchbox or tool box, without much chance of being noticed.

The fact that when in this “collapsed” mode, the solid left wall of the rear receiver would be between the magazine well and the barrel would be an extra bit of safety. Especially considering that, with the lockwork (searage) mounted on the right rear, retracting the front half to close the weapon up would also automatically sear the bolt, bringing it to ready-to-fire mode.

BTW, if you look at the picture with the pistol grip folded, the channeled cutout in its front has just enough clearance under the rear receiver to allow the front half to slide shut under it.

As the old saying goes, “By George, I think you’ve got it!”

🙂

cheers

eon

Well that’s spiffing Eon old bean, tally ho! Onto victory for Blighty and whatnot, golly gosh : )

Pip pip, and all that! 😉

PS- If the gadget works as you diagrammed, that ring-bolt probably is a catch. It may hold the forward section latched all the way back; pull it, and the catch releases allowing the forward section to slide all the way forward and lock.

If there is a double spring (inner and outer) in the guide rod system to run the slide forward, pulling on the ringbolt would SNAP the gun open in a split-second. There might be a spring to snap the pistol grip down to firing position, too. (A simple “mousetrap” spring in the pivot would do it.)

If so, an SOE agent jumping into France or debussing from a Lysander could land with this hanging off his jumpsuit with a 20-rd Lanchester box in position. German soldier pops up with an MP-40, SOE man (or woman)pushes down on innocuous-looking “thing” against snap-hook hanger- and with a SNAK sound, has a loaded and cocked 9mm SMG in hand.

Mind you, said SNAK would probably induce German with MP-40 to start the fireworks. But he’d have lost his firepower advantage.

cheers

eon

A model to test the “double spring (inner and outer) in the guide rod system” proposal would be interesting. A functioning model of the weapon, out of say wood or something. I think the method is plausible looking at the layout of Andrews as available, and in principle the suggestion would impart the appropriate types of tension on the bolt and forward section simultaneously while facilitating the collapsible nature of the weapon. In which case the ringbolt must have a purpose other than that of a cocking handle, because it is cocked by pulling the front section rearward via holding the magazine. And I concur that moving it in some manner is likely to open the gun from a collapsed position, doubling as a lanyard loop with said lanyard being utilised thus even. If the magazine catch doesn’t double as a locking method between the two sections “via some modification to it, or some other method” then there may be a kind of lock knife locking bar between the collapsed sections which engages when they expand, then the ringbolt could be used by say pushing it forward to depress said bar allowing you to collapse it again. The bolt in the cocked position would be around the right area of the trigger mechanism, so one assumes it would be simply held back by it somehow.

So to that end, as I haven’t got access to a computer currently. The drawing/plan is to modified thus, 1. The springs shown around the inner guide rods to the rear are defunct, and therefore they are to be removed. 2. The forward guide rods are to be modified, instead of a “tube” type guide rod being inserted into threaded sockets attached to the front panel of the weapons forward section. The tubes themselves will have threaded ends, both ends – and they will be inserted through holes in the front panel and welded in place so the front threads protrude as shown, the bolt will run these guide rods. Springs will then be placed over them so they rest behind the hole in the bolt for the rods, two nuts “which fit inside the holes in the bolt for the rods” will then be attached to the rear threads of said rods, so they sit behind the bolt as shown.

3. The springs removed from the rear guide rods are placed inside the front guide rod via it being a tube, were they rest on the top of the rear guide rods which are solid, these rods will compress the springs when a threaded end cap is screwed onto the protruding front threaded section of the forward guide rod. 4. You are to dress as a stereotypical French peasant Onion seller and run a cord tied onto a piece of dowell held in your hand, while stood up with your arm against your side, through your coat sleeve, over your shoulder, behind your neck, down over your chest were it is to be tied onto the “ring pull” of the Andrews. A further cord formed into a slip knot at one end will be tied onto said ring at the other, this loop will then be put over your other shoulder with the slack “enough to become taught when the Andrews would be around waist height” hanging below it. You are then to practice releasing the dowell so it shoots up your sleeve allowing the gun to fall out of your coat at the bottom from being tucked under your armpit, in so doing the pin will be pulled by the other cord becoming taught and the gun will conveniently expand in your hands at the hip were you will slam in a magazine and make noises such as “KANNNA! KANNNANNNA!” with appropriate firing replication movements at imaginary Germans who will make noises such as “AIEIEEE!, ARRRRGH! NEIN LIBERFRAUMILCH!” etc. Congratulations you won the war solider, treat yourself to a cup of tea.

You know, I think we may have determined that internally, this widget would have been slightly more complicated than a Hagelin M209 cipher machine. That might have been what killed it.

Quite aside from the potential for something not working, there’s the cost factor. SOE was interested in items that could be rapidly mass-produced, preferably cheaply. Their prototype 9mm “folding revolver” of 1942 was a good example. (See Ezell, Handguns of the World, pp. 515-16.)

Similarly, the Welrod was only about as complex as a .22 bolt-action rifle. Even its suppressor was mostly made of stampings (the baffles).

This gadget would have probably required machining, etc., equal to about three Sten MK IIs. They probably couldn’t have produced enough of them to be worthwhile in the time, and with the resources, available.

It falls into the “incredibly interesting, but questionably practical” category. OTOH, Andrews may have come up with the overhung bolt principle before anyone else did (except maybe the team that developed the EM2 machine pistol), so he gets kudos for that.

cheers

eon

I think your right Eon. So well done Mr Andrews, your good self and everyone else.

Huzzah!

I am pretty confident we have established a potential mechanism which would allow it to cock, and collapse in a viable manner. However how are the two sections held together? Because it appears they are fairly flush with each other, I think the answer may lie in the inner telescopic rods to the rear which are attached to the back panel of the receiver in my opinion. At there top they could have a threaded hole in them, and the forward rods which pass over them could be wider than required for this via there bottoms being blocked and drilled with the appropriate sized hole for the telescoping rod to pass through it. A threaded Phillips head bolt could then be dropped through the top via the end caps being unscrewed and screwed into the hole in the inner rod, the bolts head gripping the section around the hole at the bottom of the lower rod and therefore attaching the two sections together in the middle. Which to my mind presents a solution, also the mechanism for unlocking the two sections really must be to do with magazine catch given you cock the weapon by pulling the front section rearward “having to pull the pin to achieve this would be problematic” far easier via moving the catch in some manner with your thumb say.

To that end the “ring pull” may well serve no other function than that of a lanyard ring, although why it appears to move is somewhat bemusing.

Oh wait, it moves to unlock the two sections d’oh! But how? That still needs to be potentially established, that’s what I meant.

Who here has the facilities to construct a model, I’ll put my money were my mouth is in regards a design I will supply.

“After a conversation on the matter, etc”

$1000 it wants to replicate what is shown on the photographs while incorporating my proposal for the internals should you deem it feasible. I don’t require it to fire, aluminium no problem however it should replicate the external images as much as possible and have a functioning action.

Upon completion, you can jolly well keep it for posterity.

Bok, bok, chicken.

$1000 up what have you to lose, if you have the tools not going to cost that is it.

You keep the model.

On the photograph “Andrews machine carbine, ready to fire” you can see some sort of catch, latch, something above what is presumably the magazine release catch, yet on the “grip folded for stowing picture” this piece appears to be absent, in it’s place is what appears to be the end of some form of spring. I suggest this is the magazine release, and the other part is the mechanism to lock the two sections together.

Actually, it may well just be “thin” said piece, but that would imply there’s two pieces, which appear to have some mechanical function separate from one another.

Or in some form of symbiotic relationship, with separate functions.

Pull ring cocking feature I’ve already seen on some russian homebrew, also clandestine and compact looking smg;

(scroll to the end 2 pages)

http://amodestpublication.wordpress.com/2009/05/08/russian-homebuilt-submachine-guns/

I have some other articles on that design, it’s a real genius work when you see it disassembled.

One who made it used fairly simple methods and tools, but due to the probably extremely high skill, results are impressive…

Hmmm, I saw the ring pull one Storm. Interesting page that… Makarov rounds like, although there’s been smaller 9x19mm blowbacks. However I am inclined to believe the ring pull on this model had a purpose, other than that of cocking the bolt personally. Due to other visible attributes, such as marks on what appears to be a inner section of the weapon etc. Actually I am confident, about a potential design as aforementioned. Your sort of slamfire idea I like, in general though “thinking shotgun”

Back to front, upside down… Sort of…

Didn’t see it in the comments,

what if this is some kind of a strange open bolt blowback, where actually whole end portion (along with a grip) serves as a bolt that slams into the front portion, containing barrel (which must be held with left hand for the system to work) ?

Magwell is of course on the front portion.

Wear marks go way too far (on both sides, look at the magwell side!) to be just a “dustcover”. That is also why the trigger group is mounted on the side, so that the cutout on front portion fits over the trigger group, which can be placed only in this awkward way when you use end receiver portion as a bolt and handle.

Maybe in the end the action is somewhat similar arrangement as Hiro Komuda blow forward pistol.

If you turned the Andrews on it’s side, and had the magazine loaded from the top. Using a helical drum mag, via a method to facilitate this. The Andrews has a longer barrel, and more room for a bolt than say a Mac in the available space “Andrews folded” trigger group underneath, bit of polymer some rails…

Andrews’ SMG looks like a short-range ambush/assassination weapon.

It does not look like telescoping the gun reduces length by a significant amount …. barely the length of a pistol cartridge. The key advantage is closing dust covers.

This gun needs two sets of springs. One set forward of the bolt to extend the gun. Recoil springs are behind the bolt. Ideally springs simply wrap around guide rods.

Here is my speculation: the rear ring serves two functions, especially when firing single-handed.

A – first it helps “extend” the weapon. It would be attached to a shoulder strap (similar to an “X” armpit holster harness).

Carry the Andrews SMG inside your coat with the magazine laying horizontal across your belly.

As you approach the Nazi, you open your coat and push the gun forward.

A: tension on the ring unlocks the two outer pieces, allowing the barrel (and front grip) to slide forward. It slides forward slightly longer than the length of a (9 X 19mm) cartridge). The barrel (and fore grip) remains forward as the gun fires.

B: The ring serves as a (1-handed) cocking handle. If it jams – or you empty the magazine – you push forward (on pistol grip) again. The barrel remains a finite distance from your shoulder, while the rear portion slides forward (relative to the front grip) also pushing the bolt forward. When you release tension (on the ring) the barrel and front grip slide forward, but a sear holds the bolt back.

The bolt only moves forward (under spring pressure) when you pull the trigger.

When you let go of the pistol grip, the SMG swings back into your coat and you have both hands free to facilitate your getaway. Removing the (empty) magazine further reduces your profile.